Pedal type continuous vibration piezoelectric generating device

A power generation device, vibrating pressure technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. problem, to achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

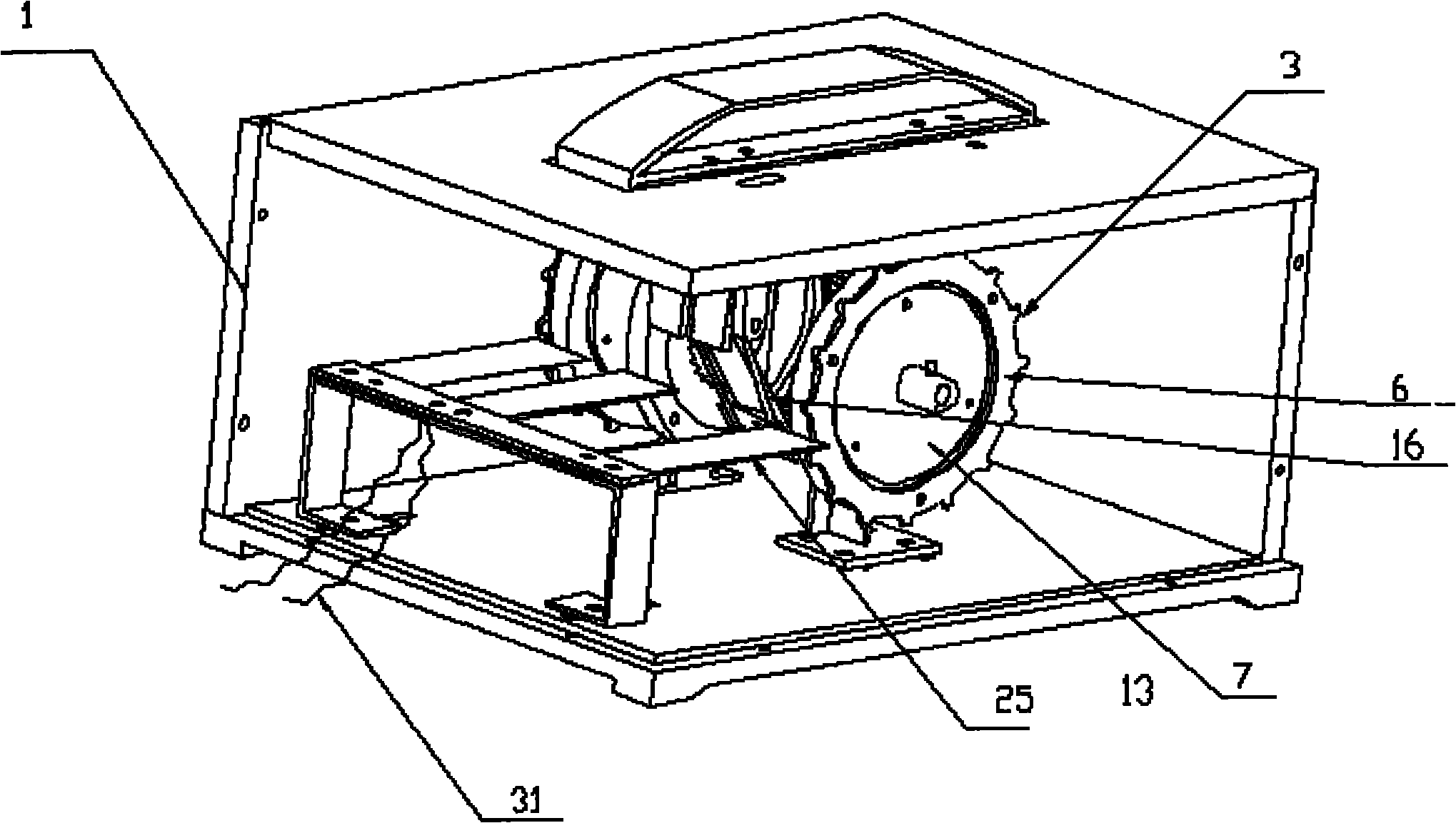

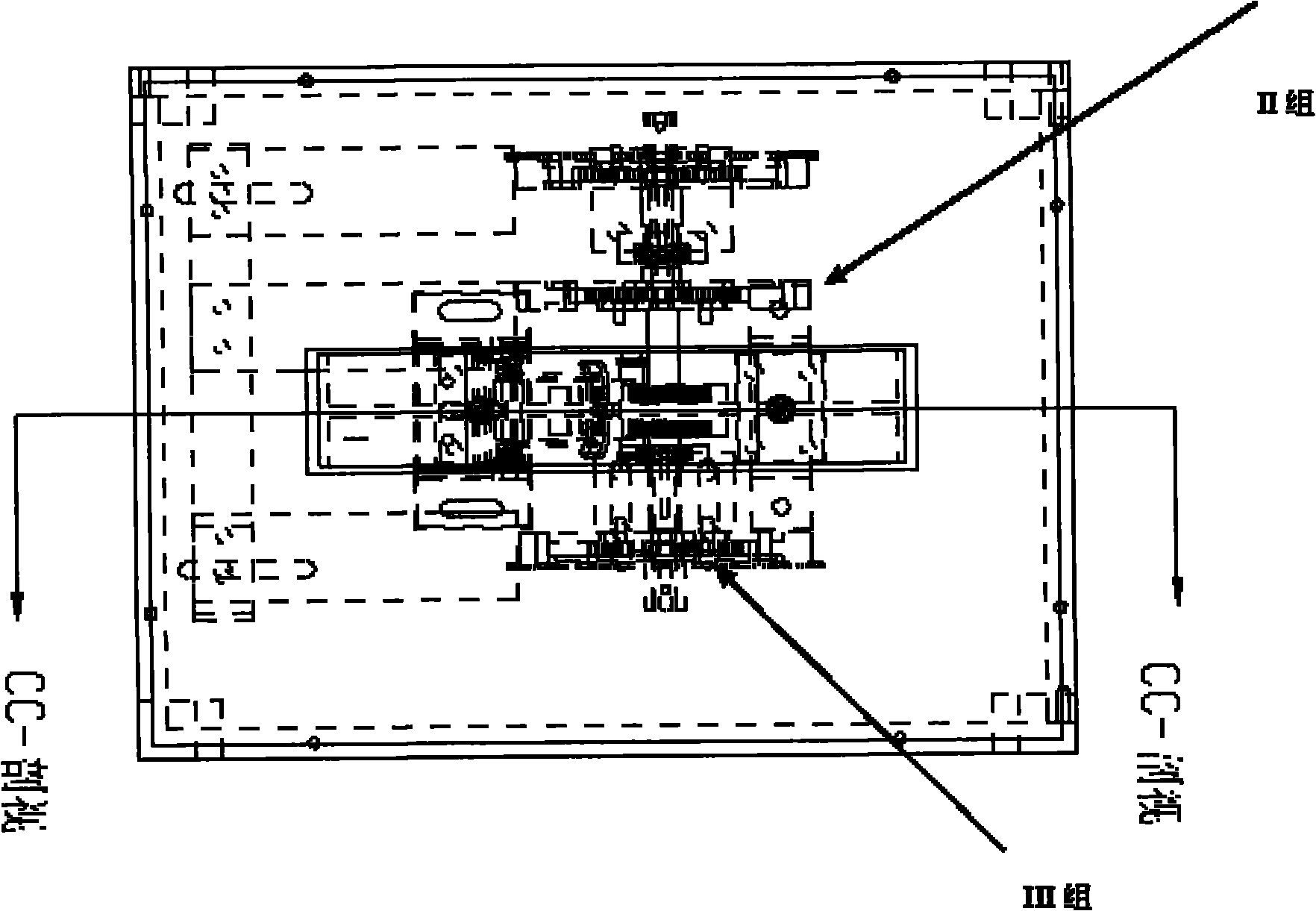

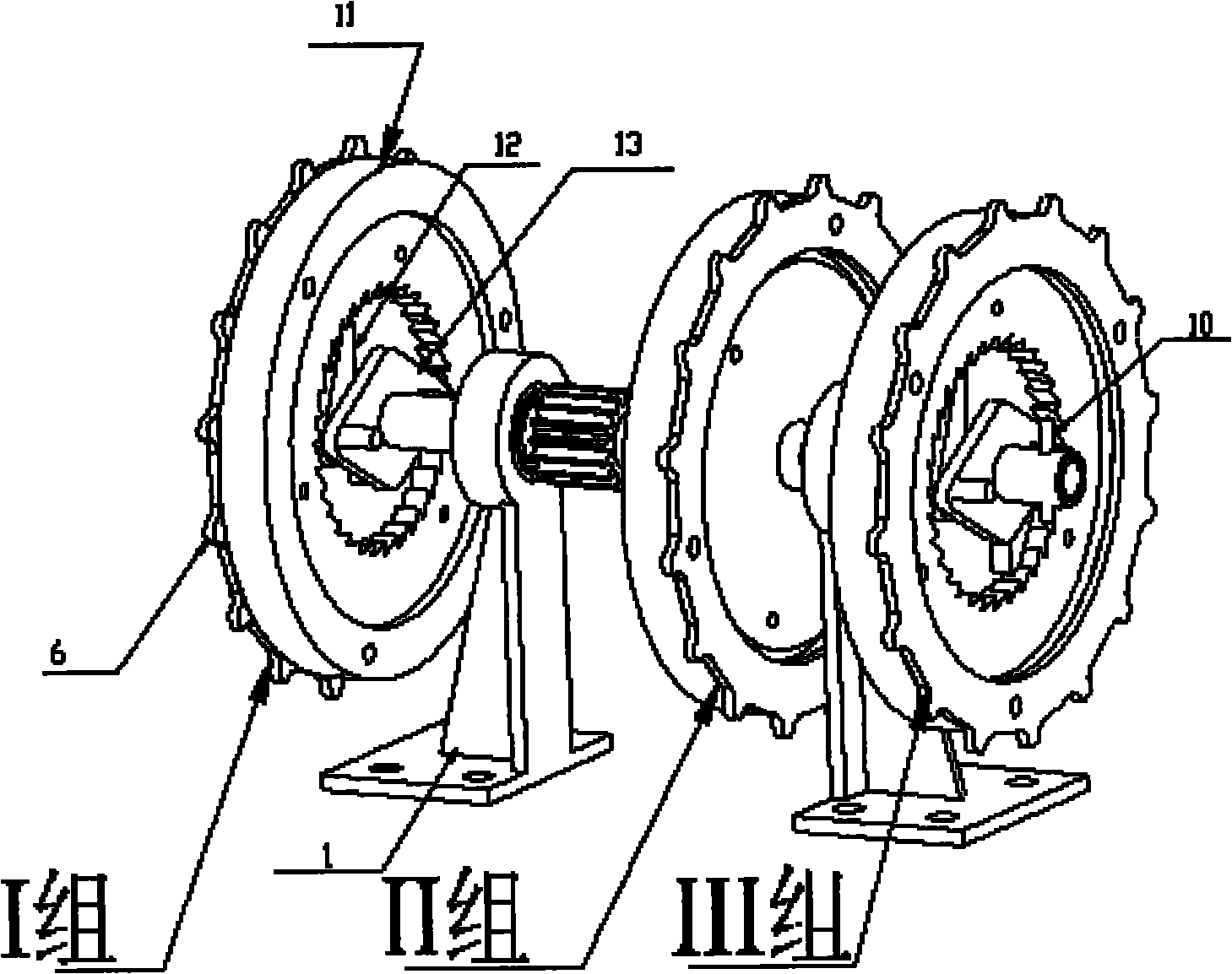

[0033] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 with Image 6 The stepping type continuous vibration piezoelectric power generation device is characterized in that it includes a central opening of the upper cover of the box body. The stepping pedal is installed through a spring mechanism, and the stepping pedal is driven by a gear mechanism to drive N groups of ratchet mechanism linkage stations. In the vibrating piezoelectric generator, N is a natural number except zero.

Embodiment 2

[0034] Example two, see Figure 1-Figure 11 , This pedaling type continuous vibration piezoelectric power generation device: a pedal 2 is installed above the box 1, and a spring 18, a small bearing 20, a gear mechanism 16 and a ratchet mechanism 3 are installed below the pedal 2. The spring 18 is installed directly below the two ends of the pedal 2 and the small bearing 20 is installed on the internal gear 21. The gear mechanism 16 is internally meshed with the pinion 15 on the gear shaft 8 by an internal gear 21 in a sector structure. The internal gear 21 is mounted on the lower end of the spring mechanism 23 through a pin 24. A reset torsion spring 22 is installed at both ends of the pin. When the pedal 2 is stepped down, the internal gear 21 is forced to rotate clockwise to drive the gear shaft 8, while the reset torsion spring is compressed; when the pedaling force disappears, the compressed reset torsion spring 22 resumes extension and drives the inner The gear 21 turns t...

Embodiment 3

[0035] Embodiment 3: This embodiment is the same as Embodiment 1, and the special features are:

[0036] The spring mechanism 23 is a support spring 18 installed directly below the two ends of the pedal 2. The upper end of the support spring 18 is supported on the upper flange of a guide rod 19, and the lower end is supported on a support plate 17. The support plate 17 is fixedly connected to the box body 1. The gear mechanism 16 is an internal gear 21 in a sector structure that meshes with a pinion 15 on a gear shaft 8. The internal gear 21 is mounted on the lower end of the spring mechanism 23 through a pin 24. The pin 24 A reset torsion spring 22 is installed at both ends, and a small bearing 20 is installed with the top end of the sector structure of the internal gear 21 and abuts against the lower surface of the pedal 2. When the pedal 2 is stepped down, the internal gear is forced 21 rotates clockwise to drive the gear shaft 8 while the reset torsion spring is compressed; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com