Device for blow-moulding containers

A technology of prefabricated blanks, clamping elements, applied in the direction of household elements, applications, passing elements, etc., to achieve the effect of simple sliding and high reproduction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

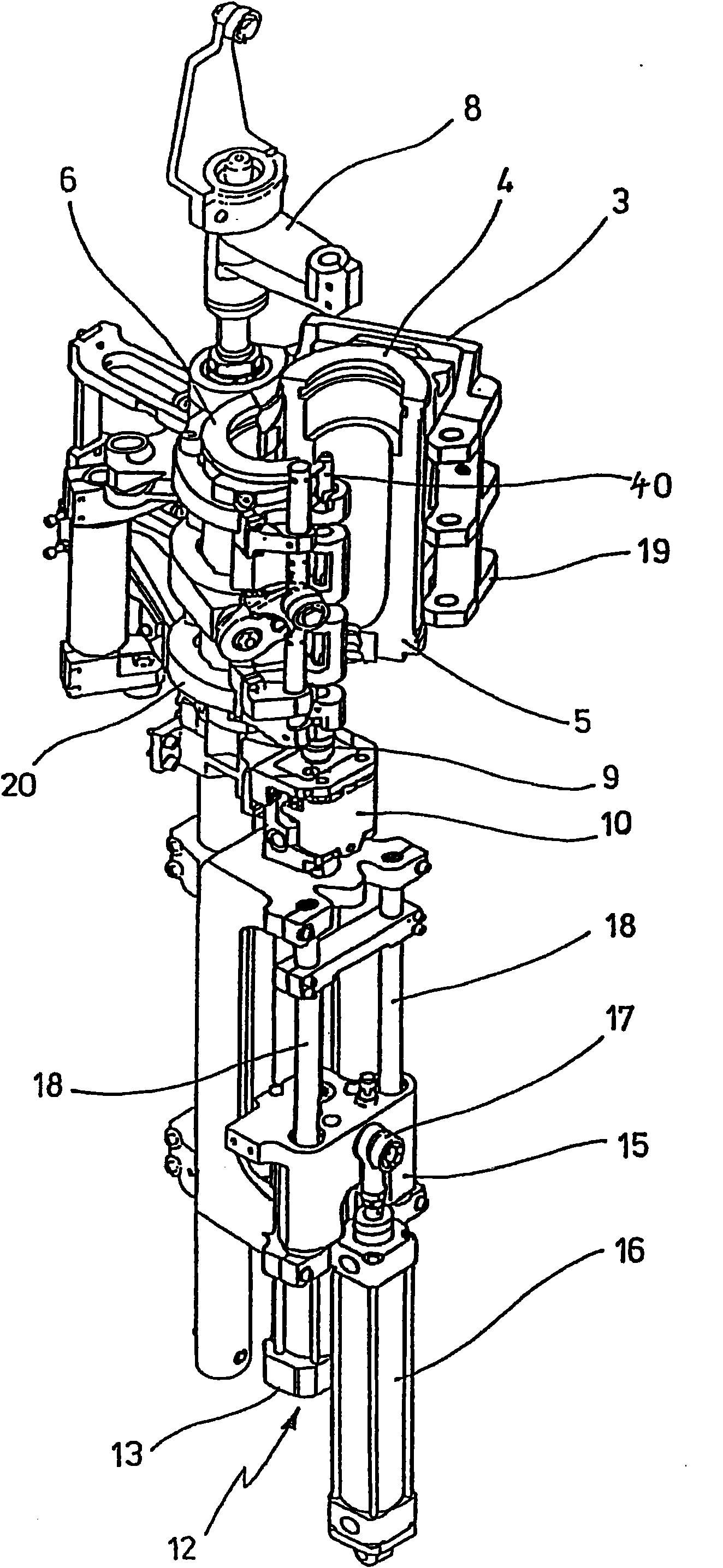

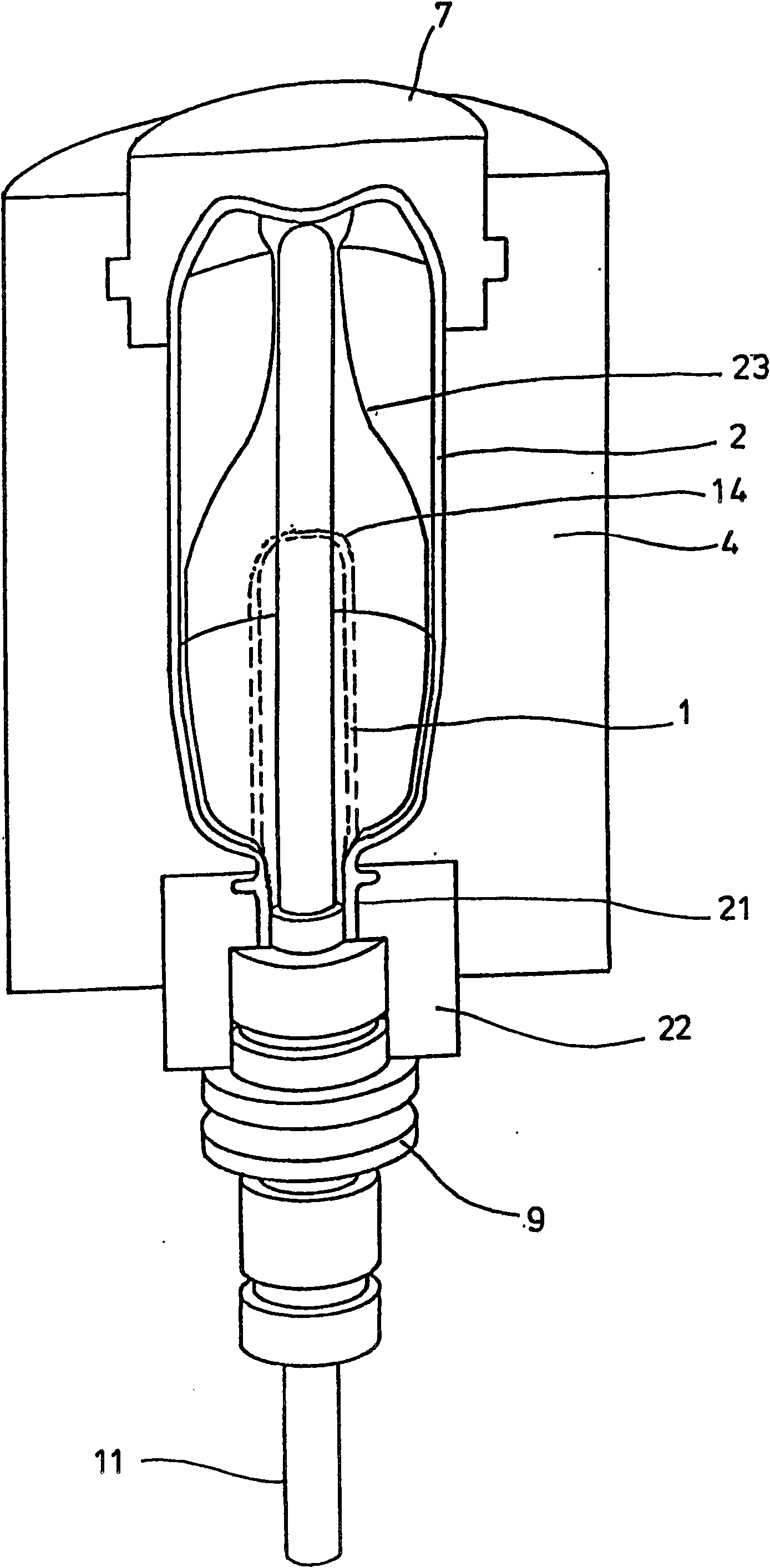

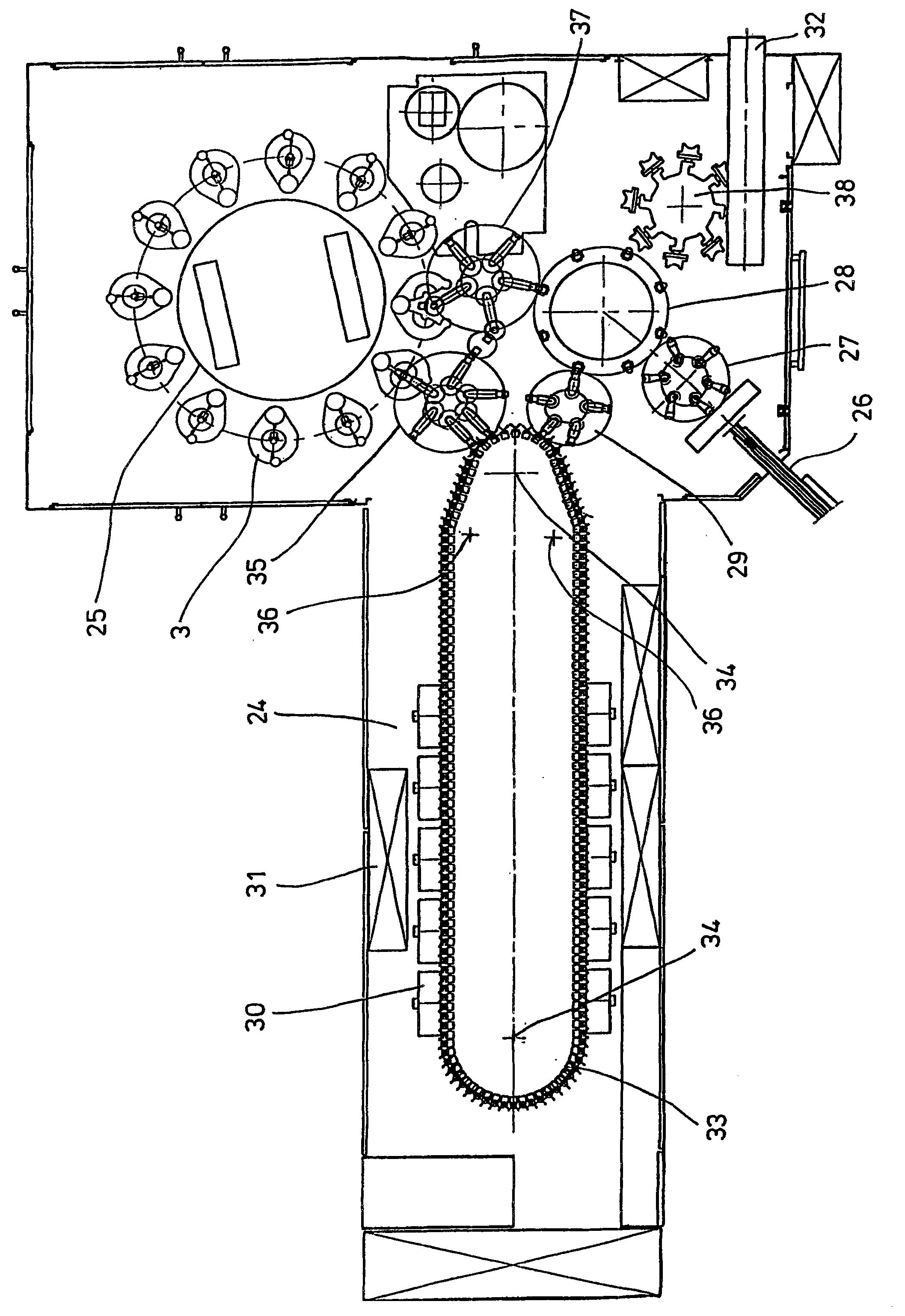

[0042] exist figure 1 and 2 The schematic structure of a device for forming a preform 1 into a container 2 is shown in FIG. The arrangement here can take place as shown or rotated by 180° in a vertical plane.

[0043]The device for shaping the container 2 basically comprises a blow molding station 3 provided with a blow mold 4 into which the preform 1 can be inserted. The preform 1 can be an injection molded part made of polyethylene terephthalate. In order to allow the introduction of the preform 1 into the blow mold 4 and to allow the removal of the finished container 2, the blow mold 4 consists of mold halves 5, 6 and a bottom part 7 which can be lifted by a lifting device. 8 positioning. The preform 1 can be held in the region of the blow molding station 3 by a holding element 9 . It is also possible, for example, to insert the preform 1 directly into the blow mold 4 , for example by means of clamps or another operating mechanism.

[0044] In order to allow the intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com