Solar stills

A technology of solar stills and solar energy, applied in the field of solar stills, which can solve the problems of expensive solar stills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

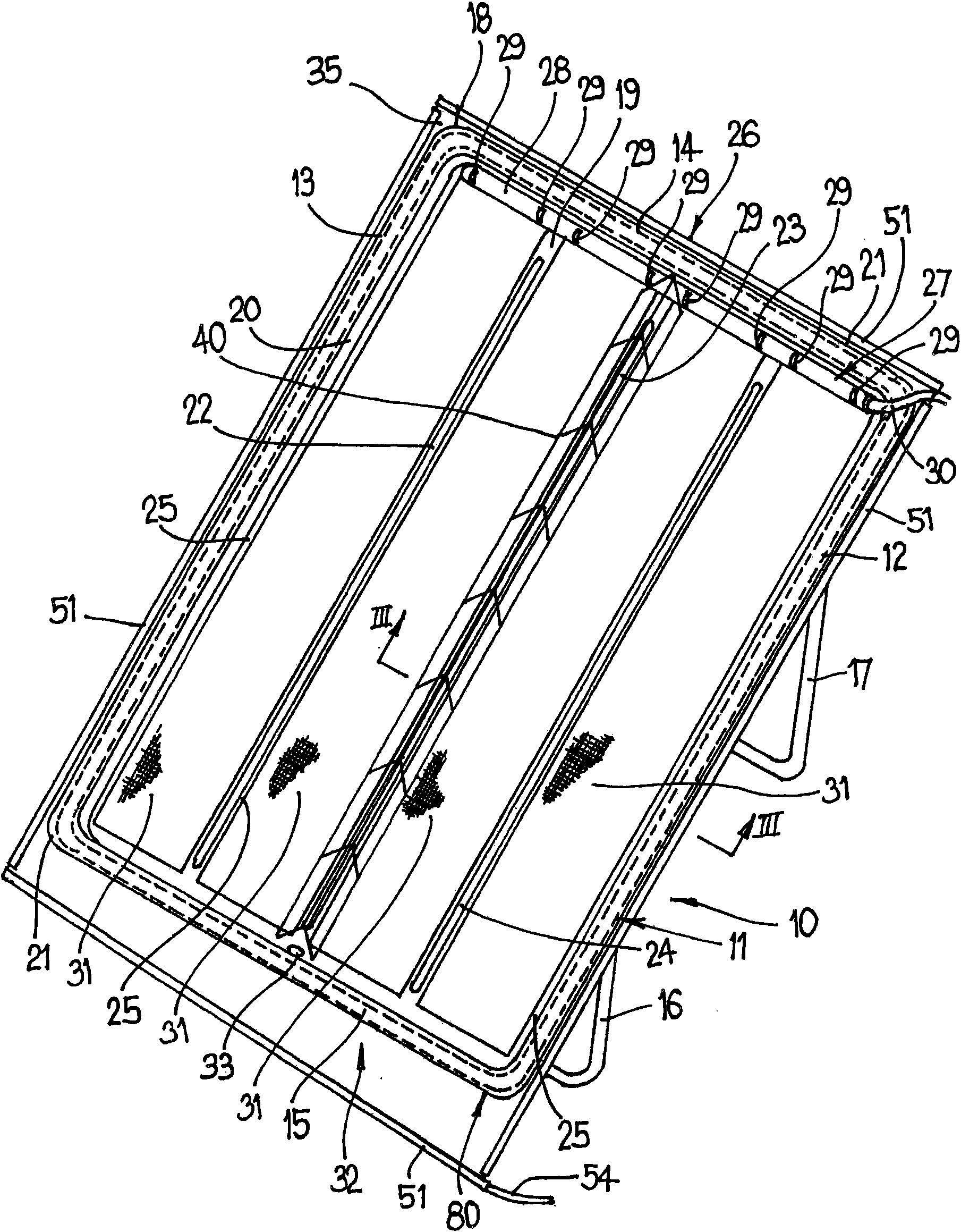

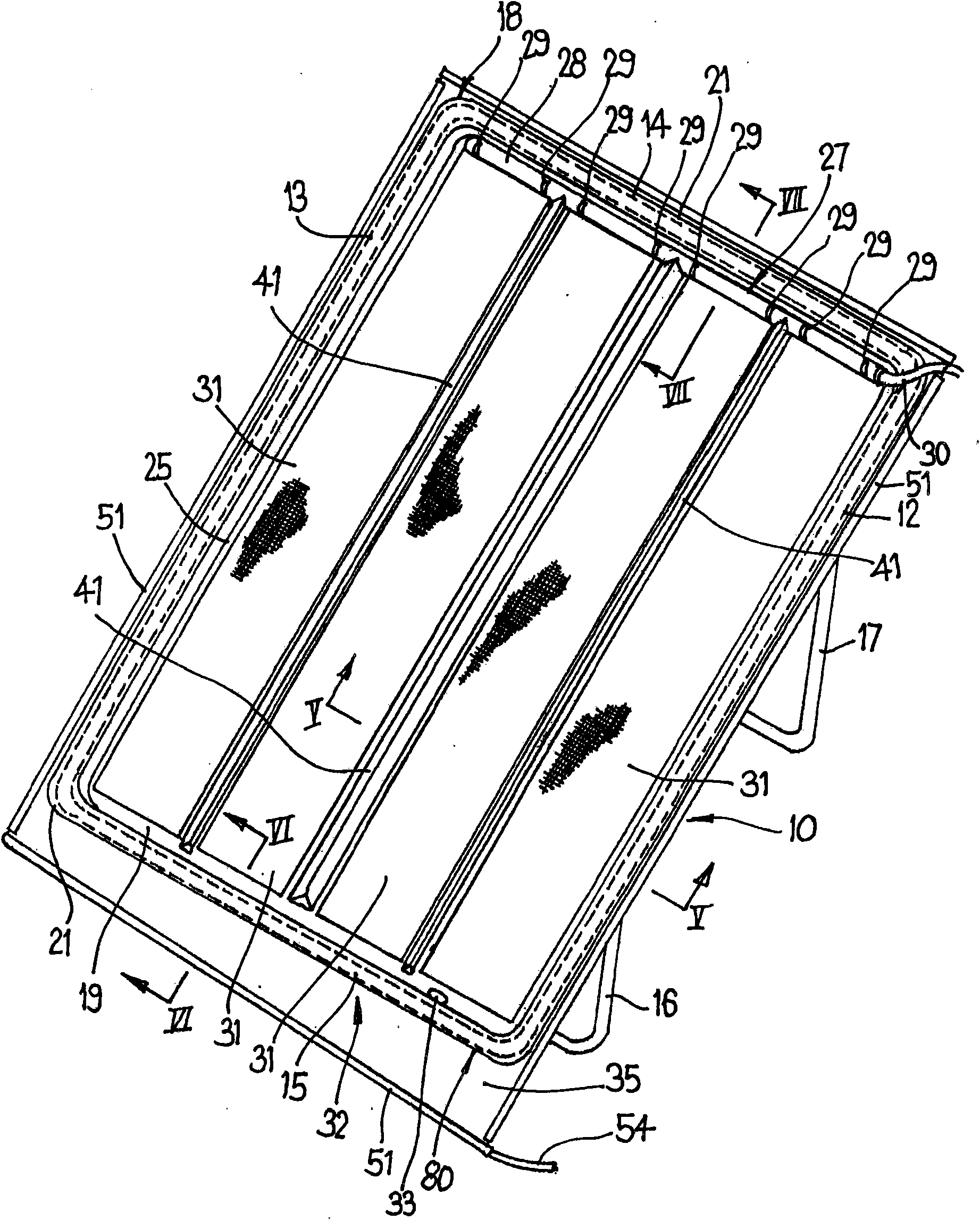

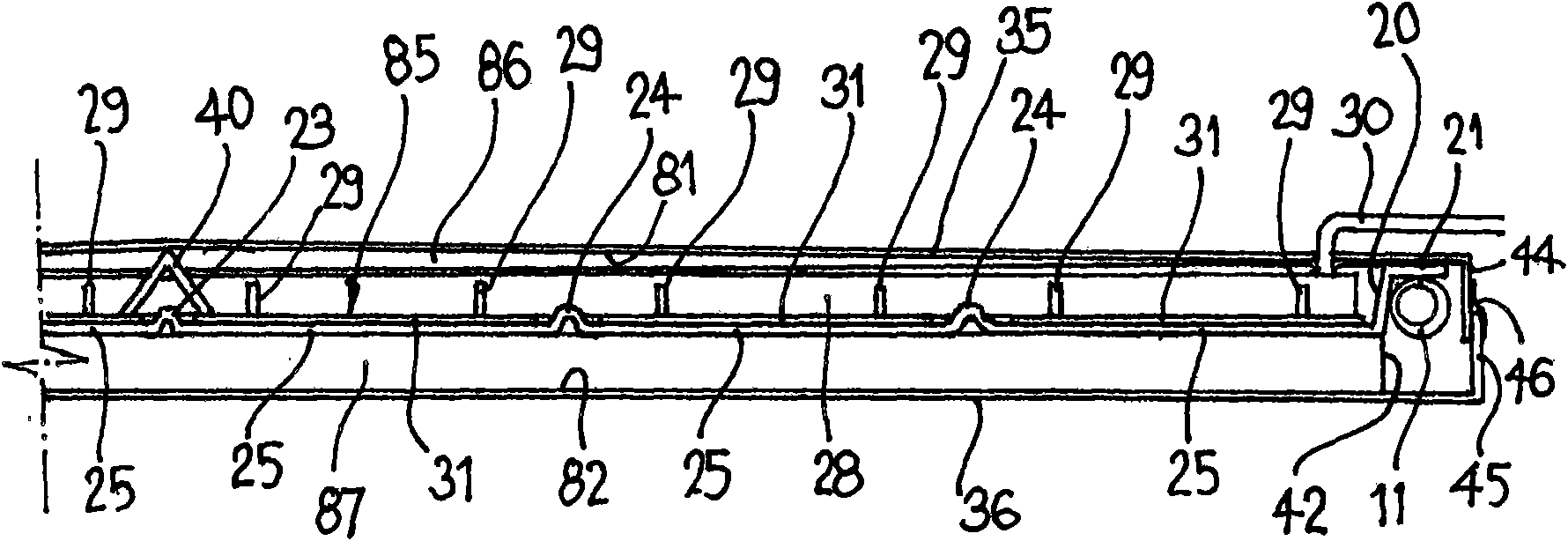

[0029] refer to figure 1 and 2 A solar still module 10 according to a preferred embodiment of the present invention has a substantially rectangular peripheral support frame 11 with longer side edge elements 12 , 13 and shorter end edge elements 14 , 15 . In use, the support frame 11 is supported by front feet 16 and rear feet 17 such that the support frame 11 and thus the solar still module 10 are supported at an inclined angle with respect to the horizontal. Any other form of support structure may also be used. Conveniently, the perimeter support frame 11 is formed from galvanized metal tubing or tubing, but any other form of elongated support frame material may also be used. In use, the angle of inclination is 10-50°, preferably about 30°.

[0030]A treatment panel member 18 in the form of a tray 80 having a base wall 19, an upstanding peripheral wall 20 and an upper outwardly extending flange 21 is provided with a method supported on a peripheral support frame 11. Lan 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com