Rotor for the compressor of a turbine engine comprising a centripetal air-collecting means

A technology for turbines and compressors, which is applied in the cooling of gas turbine devices, machines/engines, and engines. It can solve problems such as inability to reduce heat loss, and achieve the effects of reduced consumption rate, small width, and lower temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

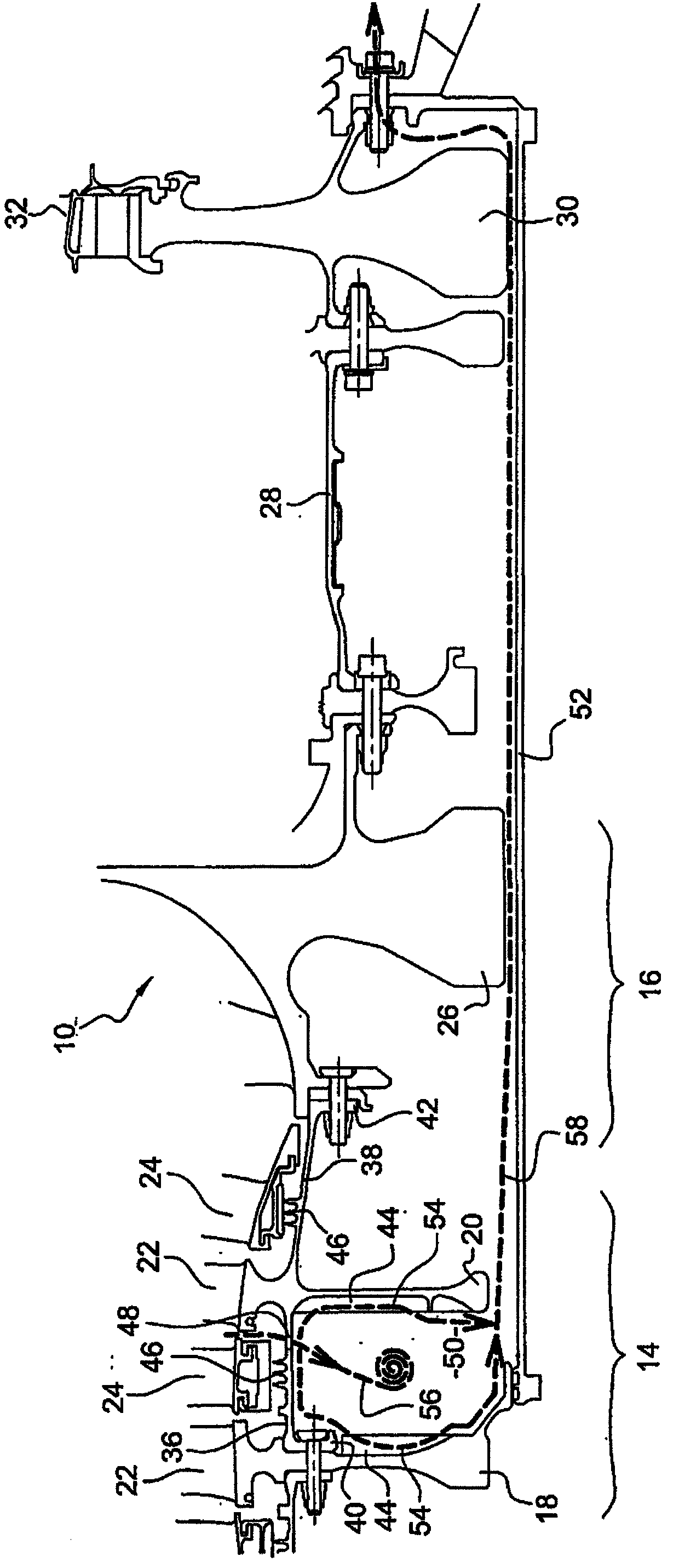

[0029] see first figure 1 , which shows part of a turbine fitted with a prior art centripetal air discharge mechanism 44,48.

[0030] The turbomachine specifically includes: a compressor, a combustion chamber and a turbine. The compressors 14 , 16 are partially shown and include an upstream module having a plurality of axial compression stages 14 and a downstream module having a centrifugal compression stage 16 . Each axial stage 14 of the compressor comprises: a rotor wheel formed by disks 18, 20 carrying blades 22 at their outer peripheries; and a nozzle 24 located downstream of the wheel and passing through an annular row of stationary nozzles Leaf formation.

[0031] The rotor disks 18 , 20 are mounted on an axis common to them and to the impeller 26 of the centrifugal stage 16 , which is itself fastened to the rotor wheel of the turbine by the inner cylindrical casing 28 of the combustion chamber. The wheel of the turbine is formed by a rim 30 which carries blades 32 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com