An apparatus, a method for establishing a conductive pattern on a planar insulating substrate, the planar insulating substrate and a chipset thereof

A technology of insulating substrates and conductive planes, applied in the direction of conductive pattern formation, electrographic pattern formation, patterning and photolithography, etc., can solve the problems of non-customization, time-consuming steps, high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

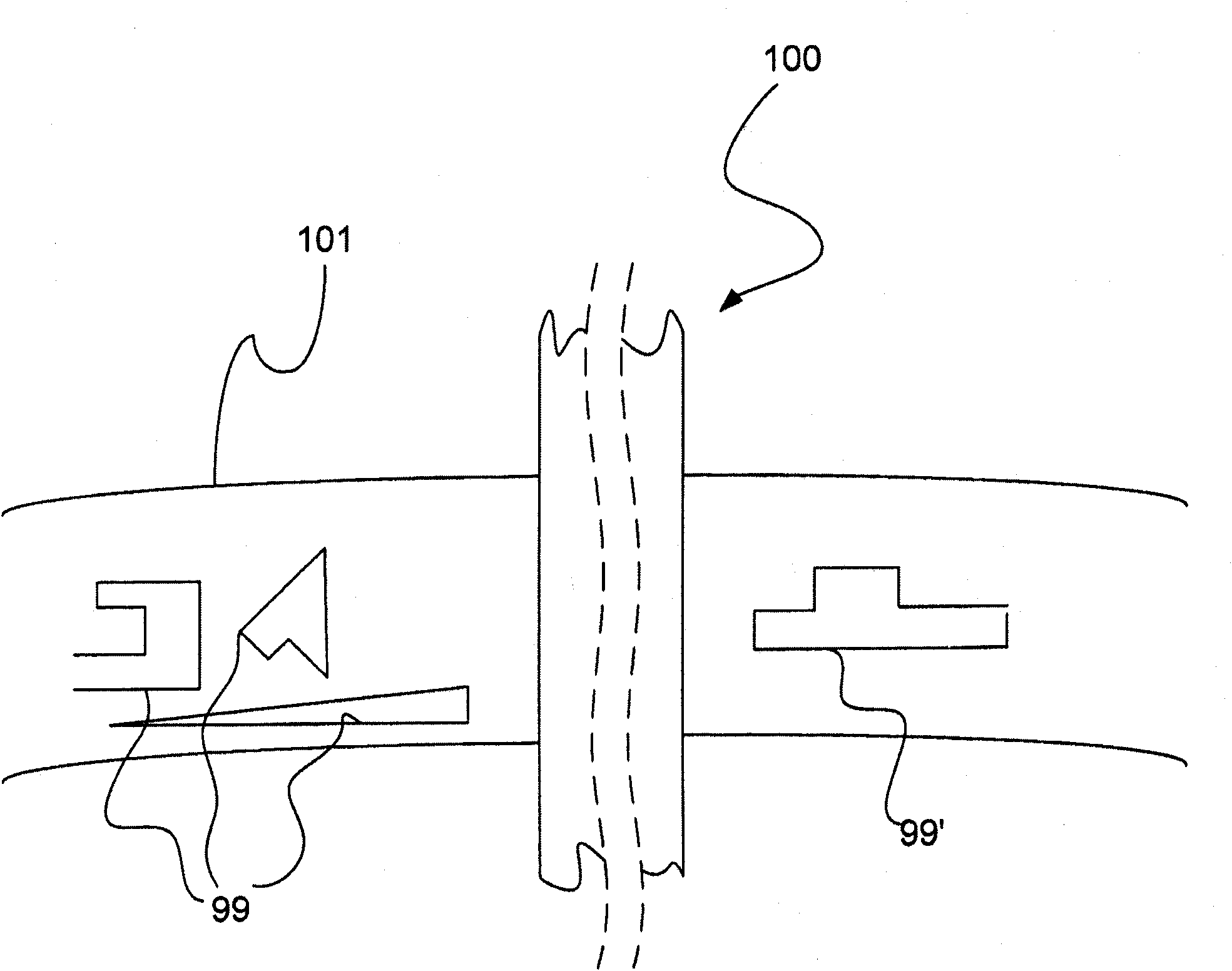

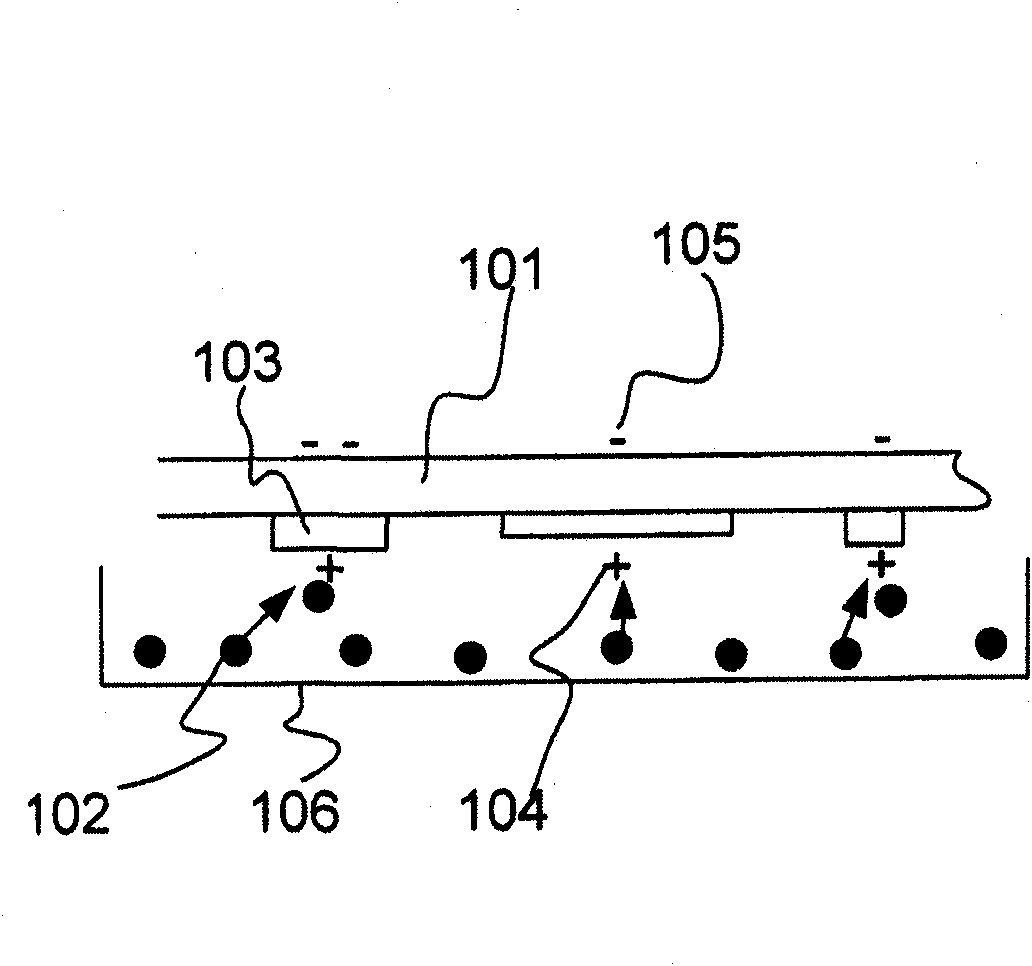

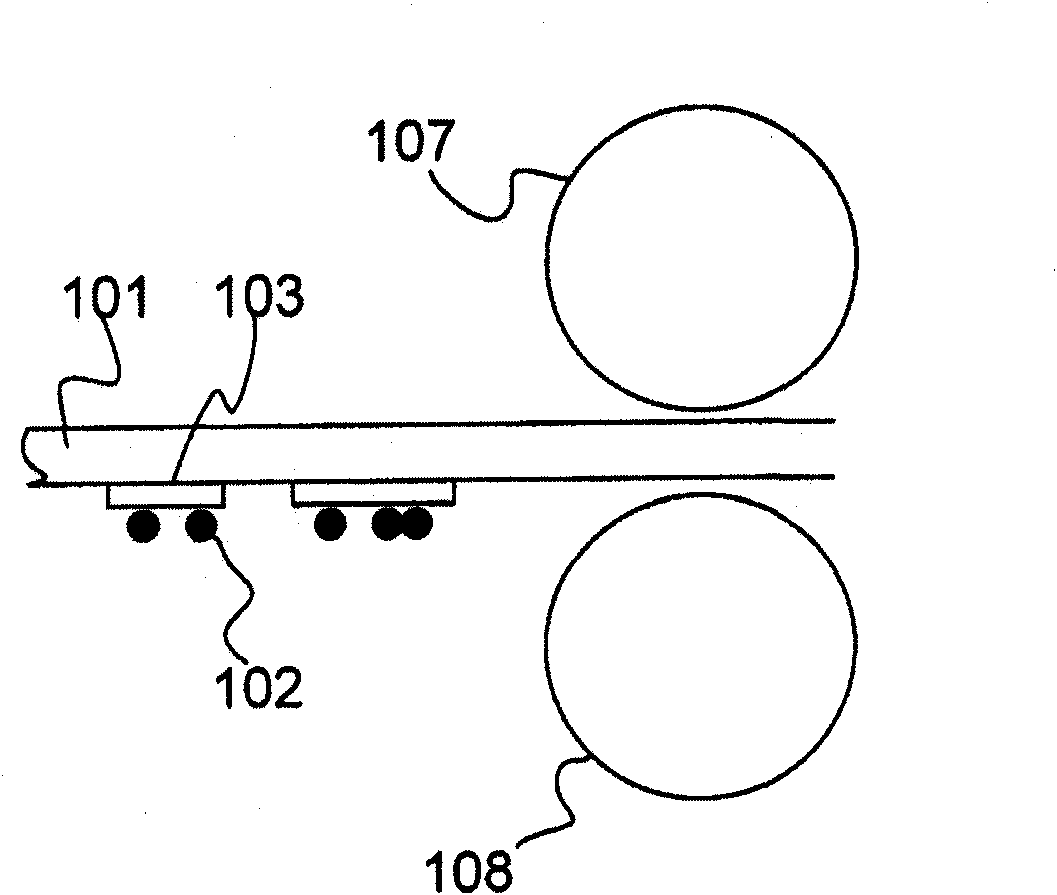

[0033] figure 1 A general view of a portion of a device 100 configured to form a conductive pattern 99 on a flat insulating substrate 101 is shown, wherein the pattern 99 is shown, in accordance with an embodiment of the present invention. Various embodiments of the invention are based on (micro)particles 102 (in figure 1 ), the particles can be deposited and permanently attached to various substrates 101 while increasing the conductivity of the pattern 99 being deposited. This can be obtained by means of at least one module of the device 100 configured to form a predetermined pattern 99 on the flat insulating substrate 101 so that the conductive particles 102 can gather according to the predetermined pattern 99 . Furthermore, at least one further module of the device 100 is configured to transfer the conductive particles to the flat insulating substrate 101, wherein the conductive particles 102 are arranged to aggregate according to a predetermined pattern. Furthermore, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com