Granular-bed gas filtering device and filtering dust removing method thereof

A filter device, filter dust removal technology, applied in the direction of dispersed particle filtration, separation methods, chemical instruments and methods, etc., can solve the problem of incompatibility between high efficiency and low pressure drop, short dust filtration time of dust filter membrane, and fine dust filtration efficiency The problem of not being high enough to achieve the effect of increasing the dust holding capacity of the bed, reducing the back-blowing gas velocity and back-blowing gas flow rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

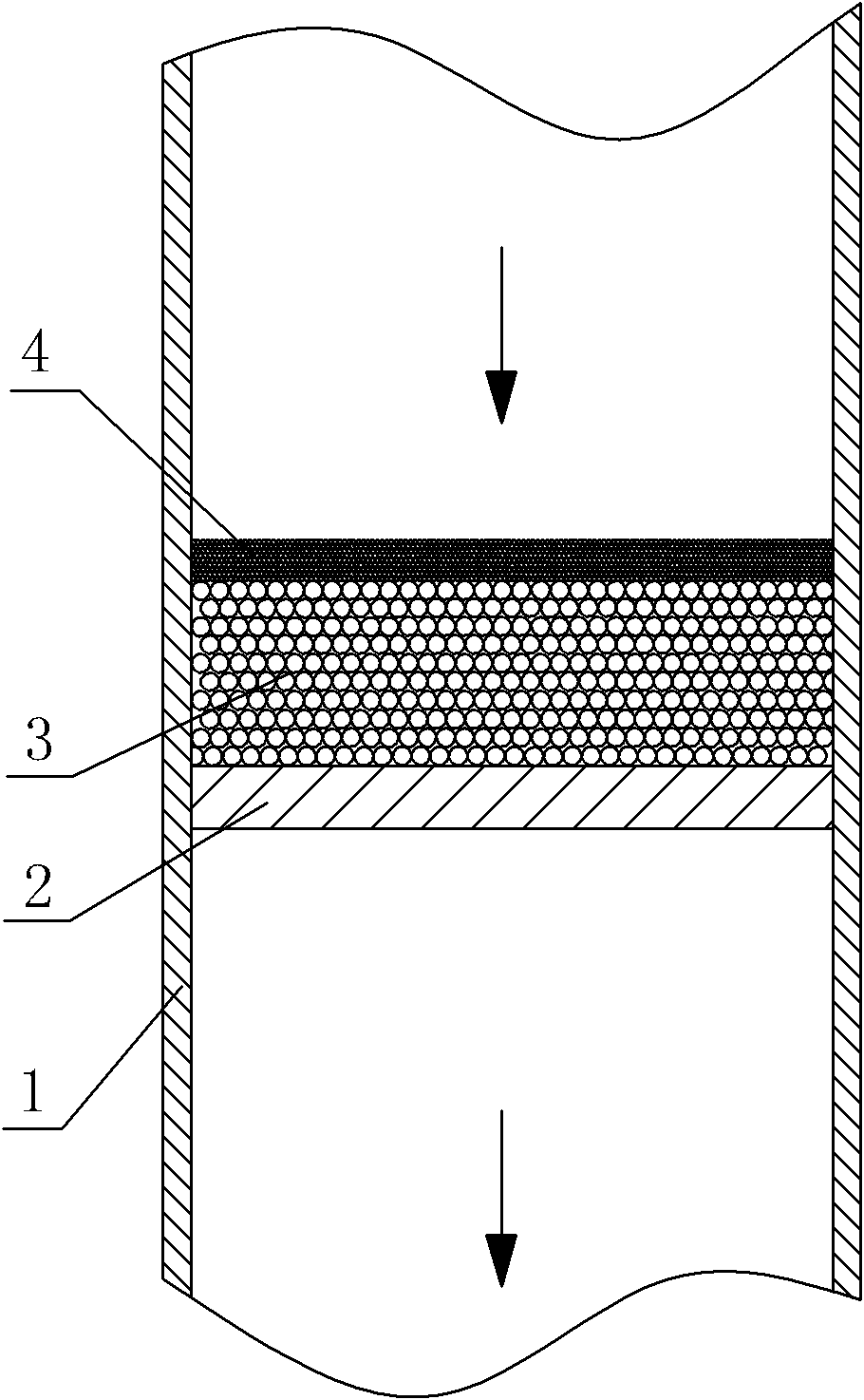

[0046] Embodiment one: if figure 1 As shown, a particle bed gas filter device includes a casing 1 and an air distribution device 2 arranged in the casing 1. A particle layer 3 is laid on the air distribution device 2. The particles in the particle layer 3 have a particle size of 0.3 to 0.5 mm of quartz sand, the thickness of the granular layer 3 is 35mm, the granular layer 3 is laid with a powder layer 4, the powder of the powder layer 4 is quartz powder of 150-200 mesh, and the thickness of the powder layer 4 is 8mm.

[0047] Utilize the filter device of embodiment one to carry out filter dust removal, concrete method is:

[0048] (1) The dust-containing gas is introduced from the dust-containing gas inlet of the shell 1, filtered through the powder layer 4 and the particle layer 3 from top to bottom, and then drawn out of the shell from the clean gas outlet of the shell 1;

[0049] (2) After filtering for a period of time, when cleaning dust, feed back blowing gas from the ...

Embodiment 2

[0057] Embodiment 2: Other structures are the same as Embodiment 1, except that the powder in the powder layer 4 is 200-250 mesh quartz powder.

[0058] Utilize the filter device of embodiment two to carry out filter dust removal, concrete method is:

[0059] (1) The dust-containing gas is introduced from the dust-containing gas inlet of the shell 1, filtered from the powder layer 4 and the particle layer 3 from top to bottom, and then drawn out of the shell 1 from the clean gas outlet of the shell 1;

[0060] (2) After filtering for a period of time, when cleaning dust, feed the back blowing gas from the back blowing gas inlet of the shell 1, and set the gas velocity of the back blowing gas to 0.08-0.13m / s, and the back blowing gas comes from the bottom While flowing upward through the air distribution device 2, the particle layer 3 and the powder layer 4, the powder layer 4 is in a fluidized state under the action of the back-blowing air while the particle layer 3 is station...

Embodiment 3

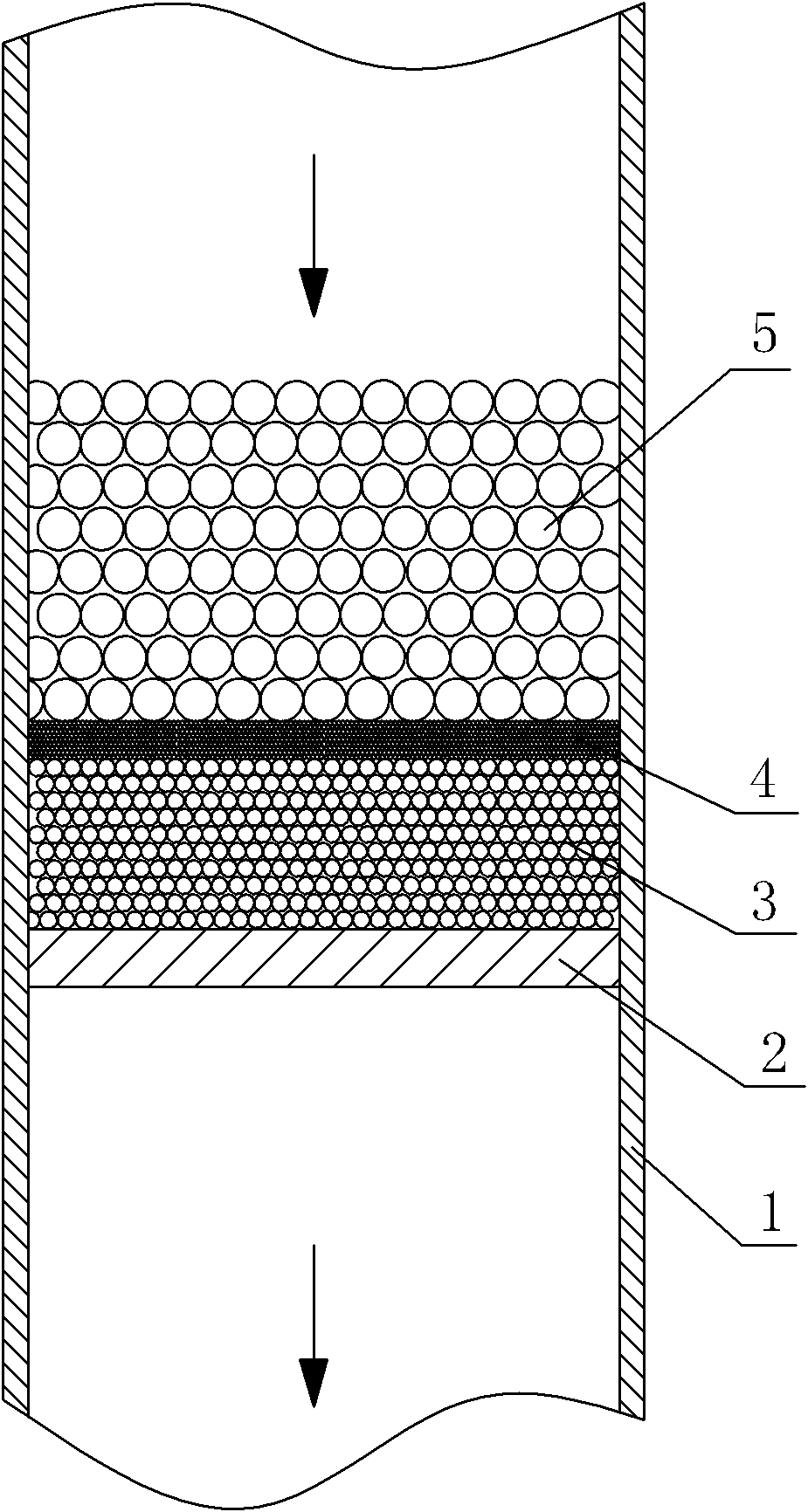

[0064] Embodiment 3: A particle bed gas filter device, including a housing 1 and an air distribution device 2 arranged in the housing 1, the air distribution device 2 is covered with a particle layer 3, and the particles in the particle layer 3 have a particle size of 0.5- 0.8mm quartz sand, the thickness of the granular layer 3 is 50mm, the granular layer 3 is laid with a powder layer 4, the powder of the powder layer 4 is quartz powder of 150-200 mesh, and the thickness of the powder layer 4 is 15mm.

[0065] Utilize the filter device of embodiment three to carry out filter dust removal, concrete method is:

[0066] (1) The dust-containing gas is introduced from the dust-containing gas inlet of the shell 1, filtered from the powder layer 4 and the particle layer 3 from top to bottom, and then drawn out of the shell 1 from the clean gas outlet of the shell 1;

[0067] (2) After filtering for a period of time, when cleaning dust, feed back blowing gas from the back blowing gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com