Airbag

A technology of airbags and sewing threads, applied in fabrics, vehicle safety arrangements, textiles, etc., can solve the problems of difficult practicality of airbags, increased airbag mass, complicated operation of auxiliary fabrics, etc., and achieve the effect of light weight and good containment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] The used warp yarn and weft yarn are nylon 66 filament raw yarn (the monofilament section is a circular section) with a denier of 310dtex / 96f, a tensile strength of 8.6cN / dtex, a tear elongation of 20%, and a boiling water shrinkage of 9.0%. The weaving density is 66 / inch, after weaving plain weave with water-jet loom, directly pass through the hot water shrinkage tank without drying, and then control the temperature T1 of the first stage to 120 by using a two-stage suction drum dryer. °C, the drying process of controlling the temperature T2 of the second stage to 125 °C is completed. The physical properties of the obtained base fabric are shown in Table 1.

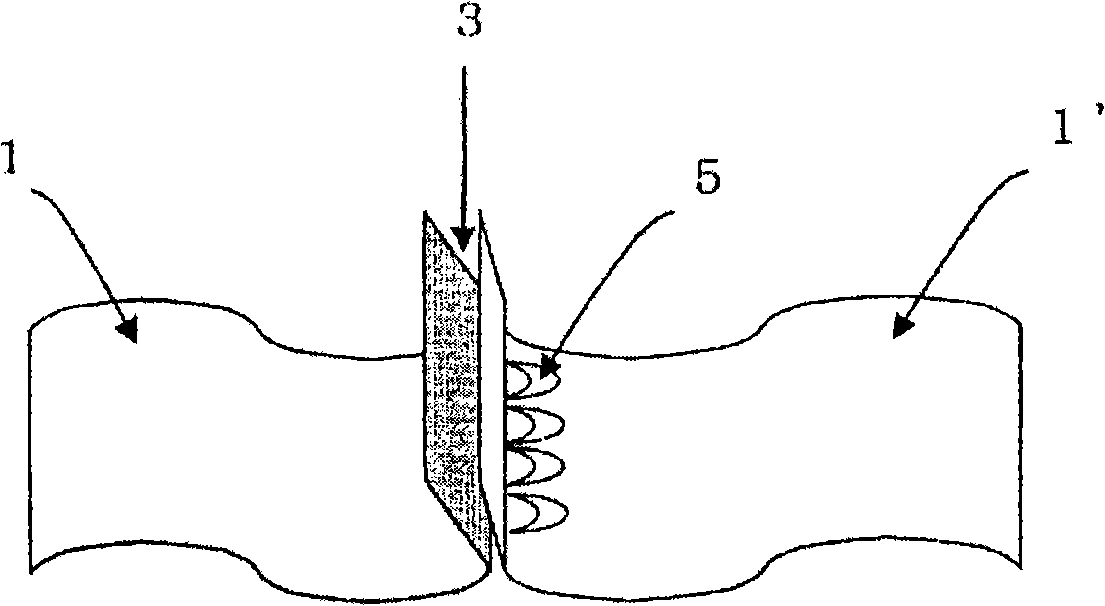

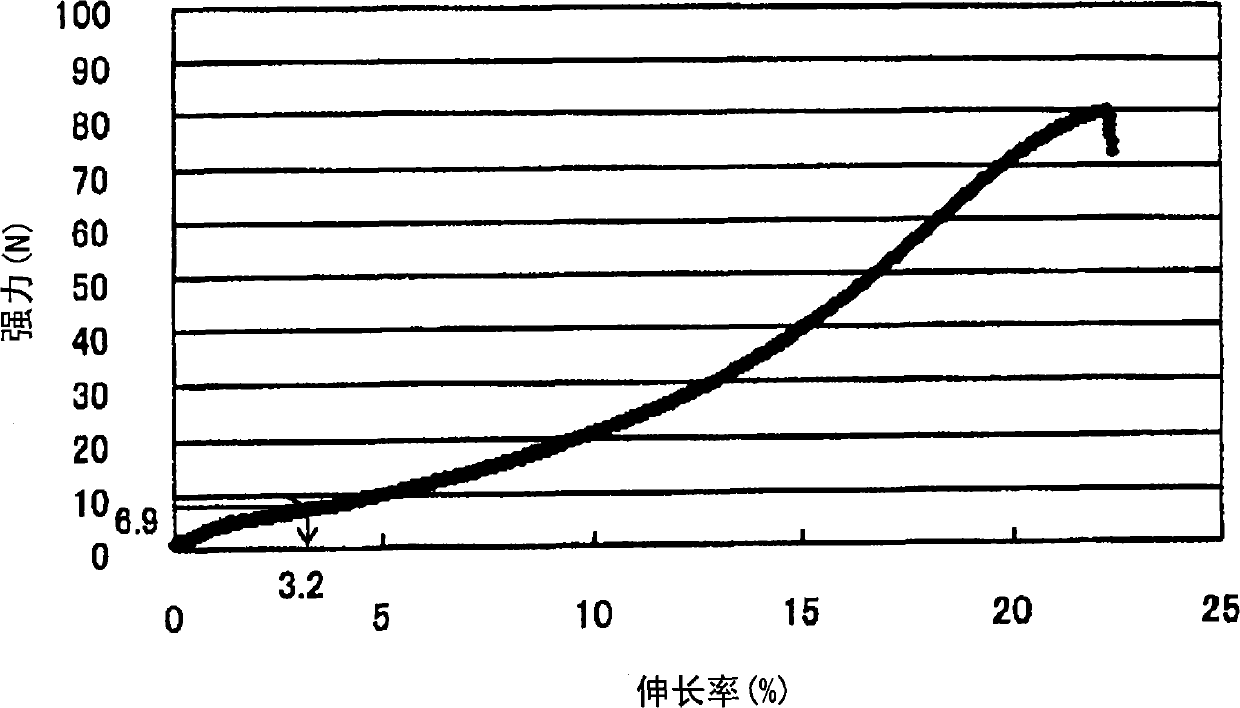

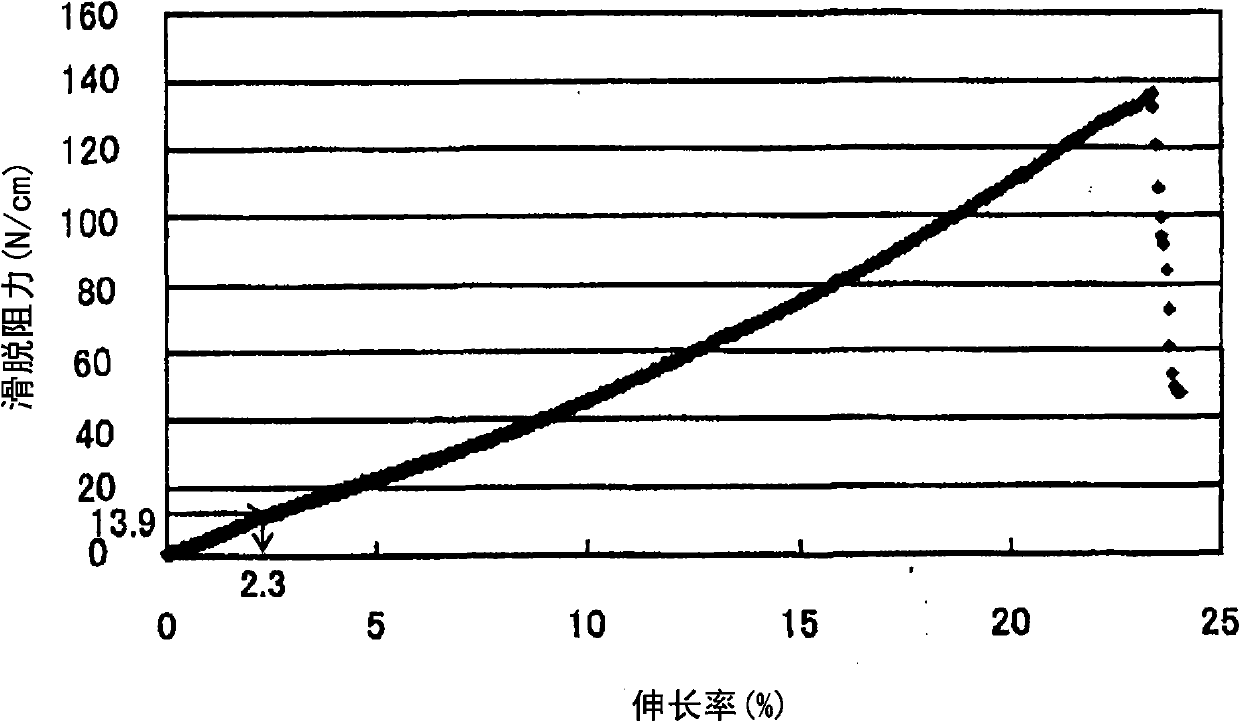

[0103] As the sewing thread, nylon 66 thread with a fineness of 920dtex, a tensile strength of 8.6cN / dtex, and a tear elongation of 22% is used for both the upper and lower threads. Flat seams are used, and the sewing needle density is 4.5 needles / cm. The above-mentioned base fabric is used. A sewn sample simulati...

Embodiment 2

[0105] A base fabric and a sewn sample were produced in the same manner as in Example 1 except that the warp and weft weave density was 63 threads / inch. Table 1 shows the results of evaluating the produced base fabric and sewn samples in the same manner as in Example 1.

Embodiment 3

[0107]Except that the used warp yarn and weft yarn are nylon 66 fine filament raw yarn (single filament section is a circular section) with denier 270dtex / 84f, tensile strength 8.6cN / dtex, tear elongation 19%, and boiling water shrinkage 9.0%. Except that the density was 70 counts / inch, base fabrics and sewing samples were produced in the same manner as in Example 1. Table 1 shows the results of evaluating the produced base fabric and sewn samples in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com