Production equipment for anaerobic digestion liquid organic compound fertilizer

A kind of production equipment and anaerobic digestion technology, applied in the direction of organic fertilizer, bio-organic part treatment, fertilization device, etc., can solve the problems of odor emission, difficulty in popularization, and reduced fertilizer efficiency, so as to improve enzyme activation and fertilizer efficiency, and improve economic efficiency. Benefits, the effect of purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

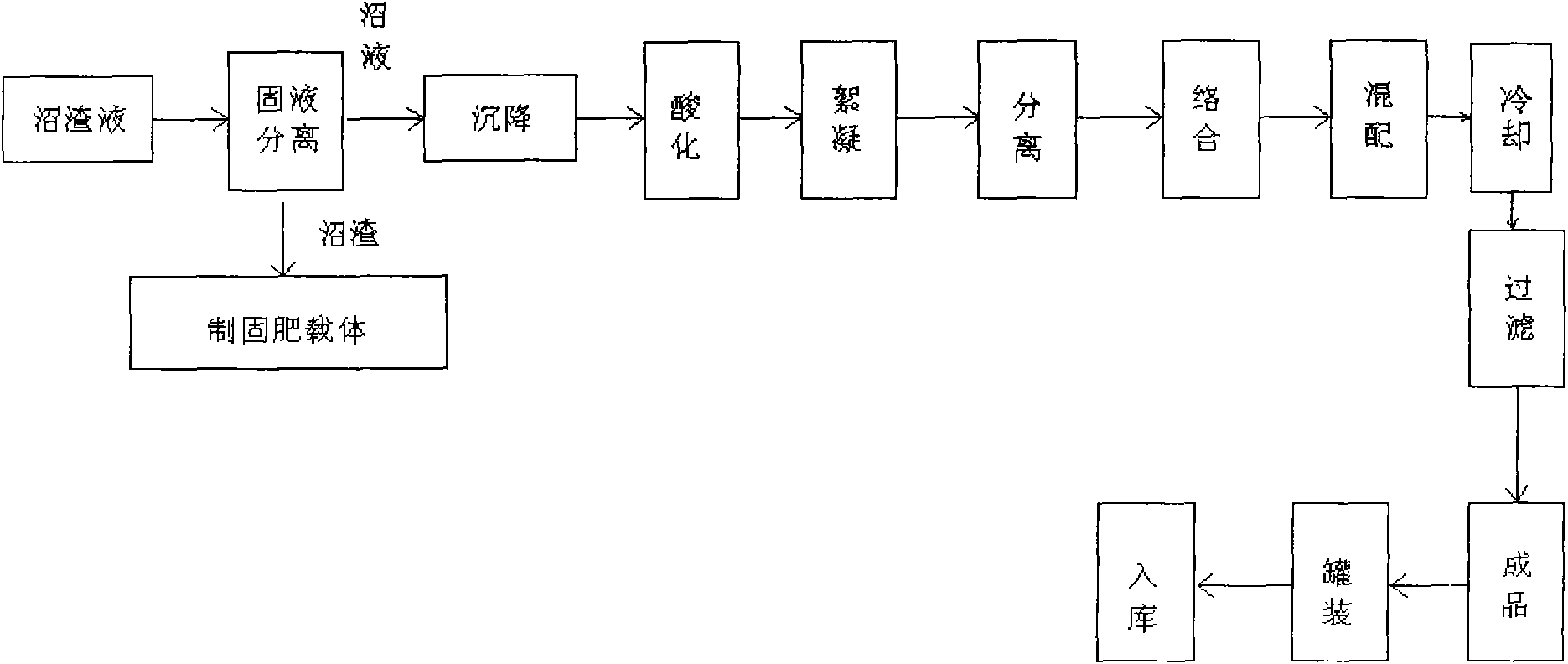

[0020] Such as figure 1 As shown, the general idea of the present invention is as follows: first, solid-liquid separation of the biogas residue is carried out, the separated biogas residue is used as a carrier for making solid fertilizer, the separated biogas slurry is settled, and the biogas residue is further removed, and then The biogas slurry is acidified, flocculated, separated, complexed and mixed in sequence, then cooled and filtered to obtain the finished product, and finally the finished product is canned and put into storage.

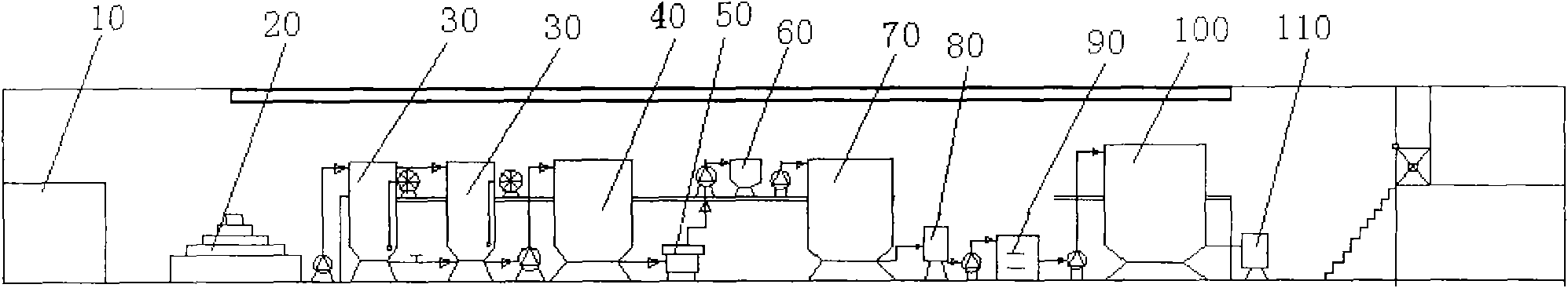

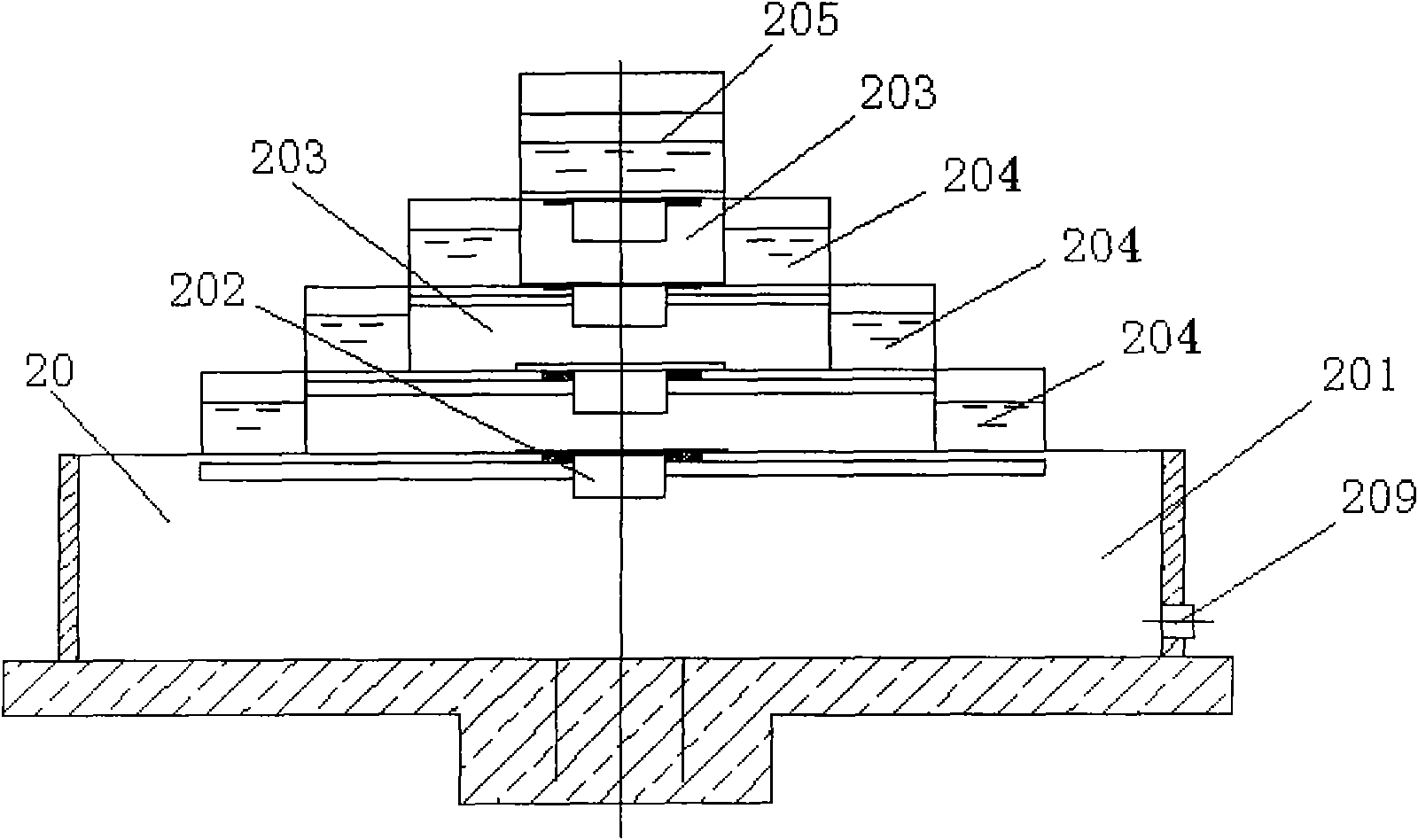

[0021] Such as figure 2 As shown, based on the above-mentioned design, the device of the present invention mainly includes a solid-liquid separation device 10, a sedimentation filter tower 20, a re-fermentation (acid enrichment) device 30, a flocculation sedimentation device 40, a high-speed separation device 50, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com