Method and device for recovering and/or enriching aqueous-phase mobilized lipases

A technology of immobilized lipase and lipase, which is applied in the direction of hydrolytic enzymes, etc., can solve the problems of increased energy consumption in the process of evaporation and reflux, high cost of immobilized enzyme preparation, and complicated treatment process, and achieve low energy consumption for recovery, no enzyme Effects of live loss and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

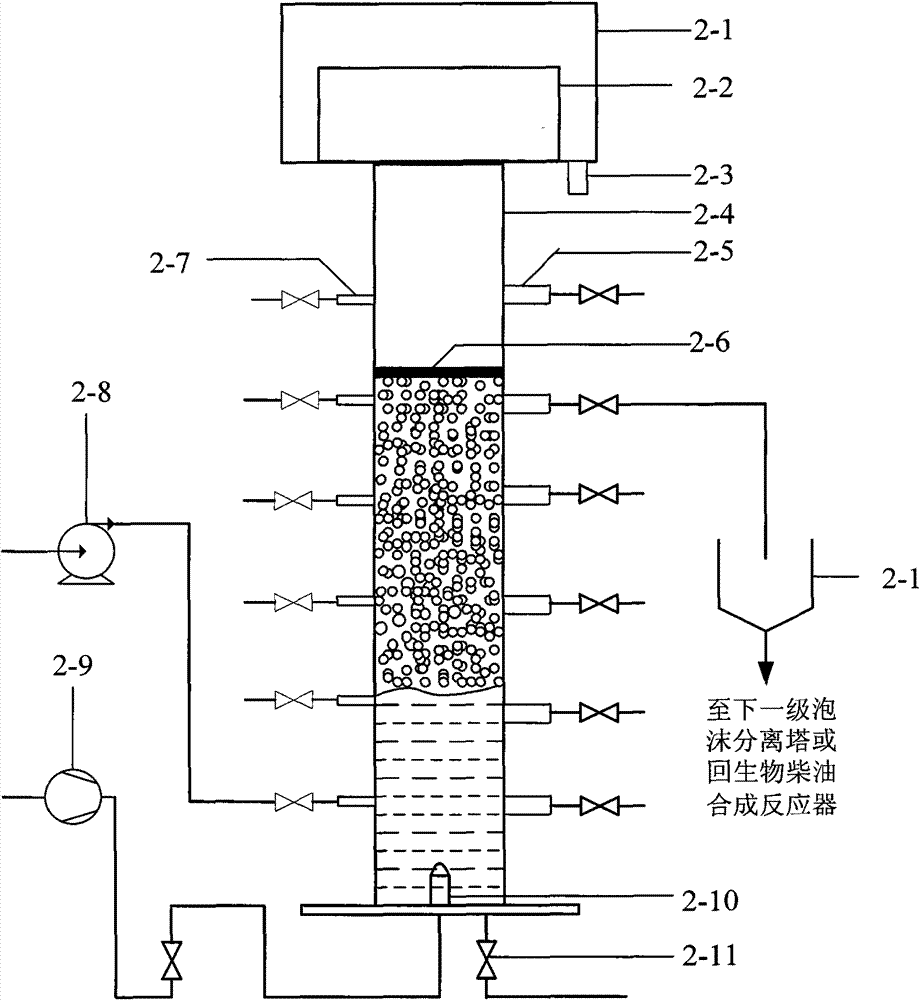

[0036] The lipase is produced by microbial fermentation, the enzyme activity of the lipase in the fermentation broth is 2000IU / ml, and the pH is 6.5. The foam separation device used in this embodiment can be found in figure 2 As shown, the specific details are as follows.

[0037] Through the external liquid feed pump 2-8, 4L fermentation liquid is pumped into the foam separation device from the foam column feed port 2-7 on the side wall of the foam column 2-4, and the external gas compression pump 2- 9 Pass the air into the foam tower 2-4 at a gas velocity of 10L gas / L liquid / h, and the gas distributor 2-10 provided at the bottom of the foam tower 2-4 distributes the air into tiny bubbles to generate foam, and the foam layer is When the height reaches twice the height of the liquid layer, start to collect the foam through the discharge port 2-5 on the side wall of the foam tower and the peripheral side line foam collector 2-1 connected thereto, and pass through the piston i...

Embodiment 2

[0040] The lipase is produced by microbial fermentation, the enzyme activity of the lipase in the fermentation broth is 2000IU / ml, and the pH is 6.5. The foam separation device used in this embodiment is the same as that in Embodiment 1.

[0041] Pour 4L of fermentation broth into the foam separation device. Air is introduced at a gas velocity of 10L gas / L liquid / h to generate foam. When the height of the foam layer reaches twice the height of the liquid layer, start to collect the foam, and always keep the height of the foam layer at about twice the height of the liquid layer. The total ventilation time was 90 minutes, and the volume of foam liquid and enzyme activity were measured every 15 minutes. The lipase activity of the resulting foam liquid at 15, 30, 45, 60, 75 and 90 minutes was respectively 7000IU / ml, 6000IU / ml, 4500IU / ml, 4000IU / ml, 3700IU / ml and 3500IU / ml; Enzyme enrichment ratios were 3.5:1, 3:1, 2.25:1, 2:1, 1.35:1 and 1.25:1; foam volumes were 0.17L, 0.53L, ...

Embodiment 3

[0043] 4L of lipase (Rhizopus oryzae free lipase) solution with a concentration of 100 μg / ml was adjusted to pH 5.0 with sulfuric acid and then poured into a foam separation device. The foam separation device used in this embodiment can be found in figure 2 As shown, the specific details are as follows.

[0044] Through the liquid feed pump 2-8 of the peripheral equipment, put 4L fermented liquid into the foam separation device from the foam tower feed port 2-7 on the side wall of the foam tower 2-4, and pass the gas compression pump 2- 9. Air is passed into the foam tower 2-4 at a gas velocity of 5L gas / L liquid / h, and the gas distributor 2-10 provided at the bottom of the foam tower 2-4 distributes the air into tiny bubbles to generate foam. After the foam rises to the top foam collector 2-1, it flows out from the top outlet 2-3 through the top guide tube 2-2. The output was collected and the aeration was stopped after 2 hours. The foam liquid is obtained after the foam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com