A ground instruction transmission method for controlling rotary steering drilling tool and an apparatus for the same

A technology for rotary steerable drilling and tools, applied in directional drilling, earth-moving drilling, flushing wellbore, etc., can solve the problems of deposition, adhesion to the surface of tools, prolonged drilling operation time, increased operation cost, etc., and achieves simple structure and controllable The effect of improving precision and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

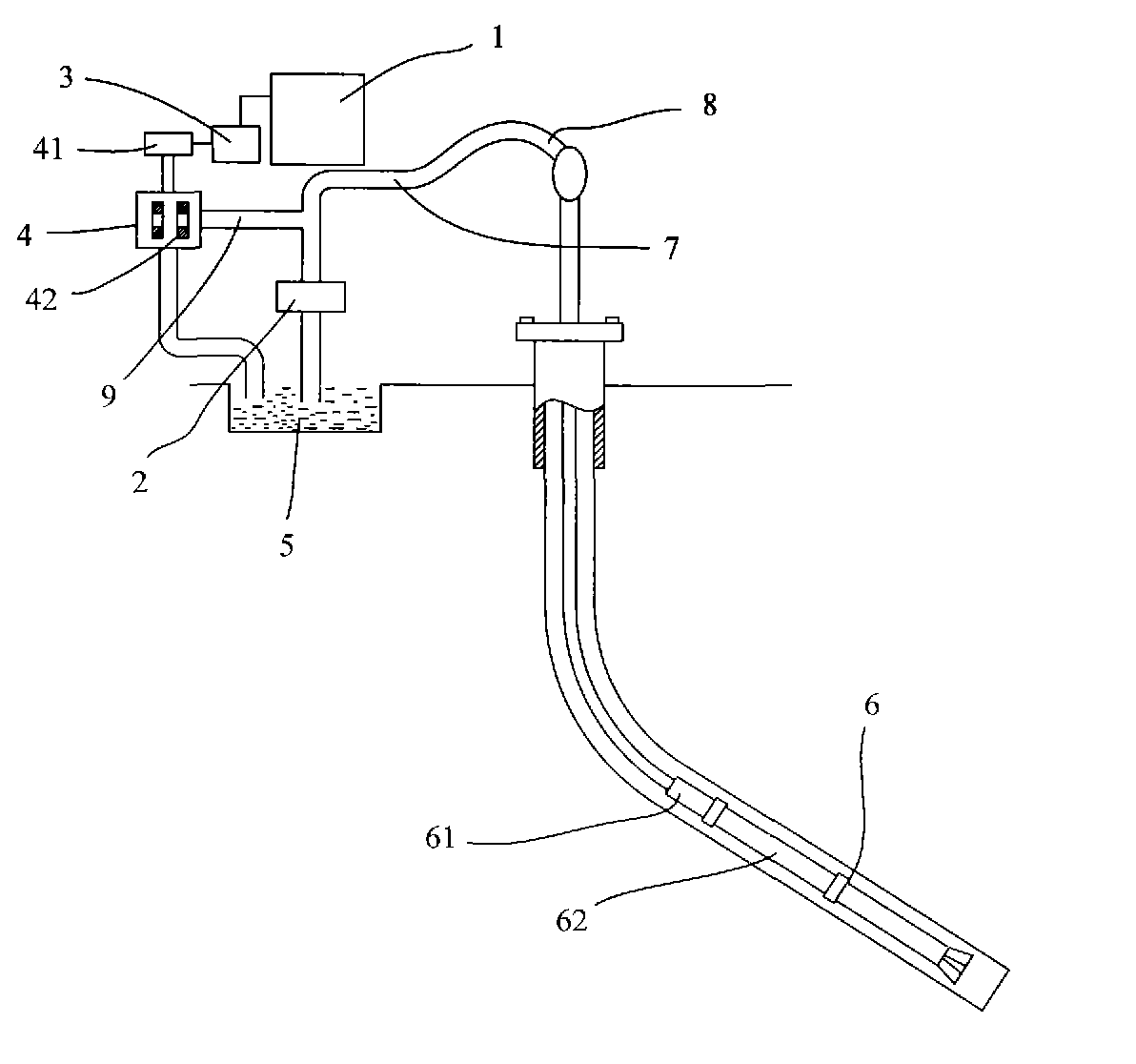

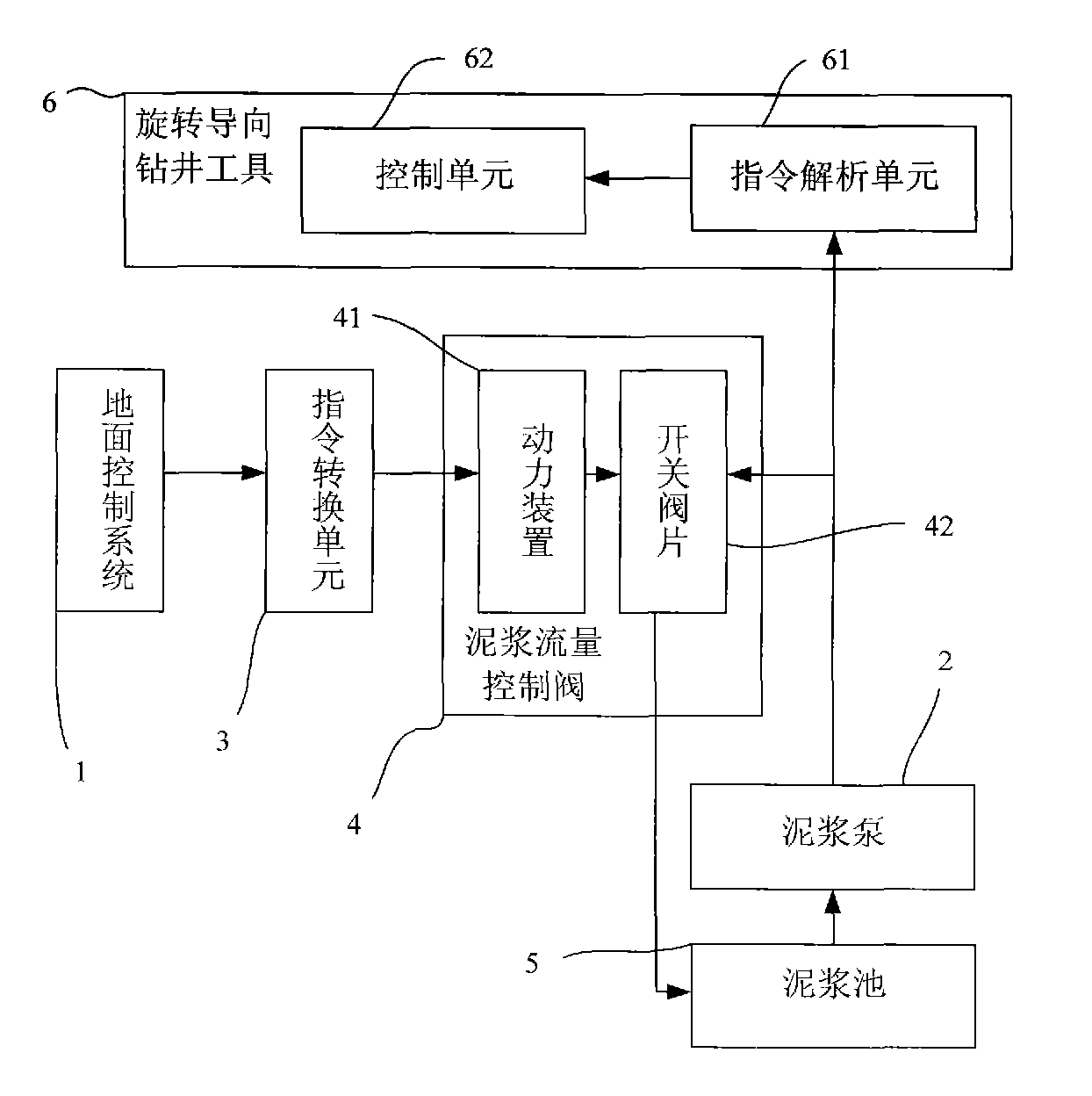

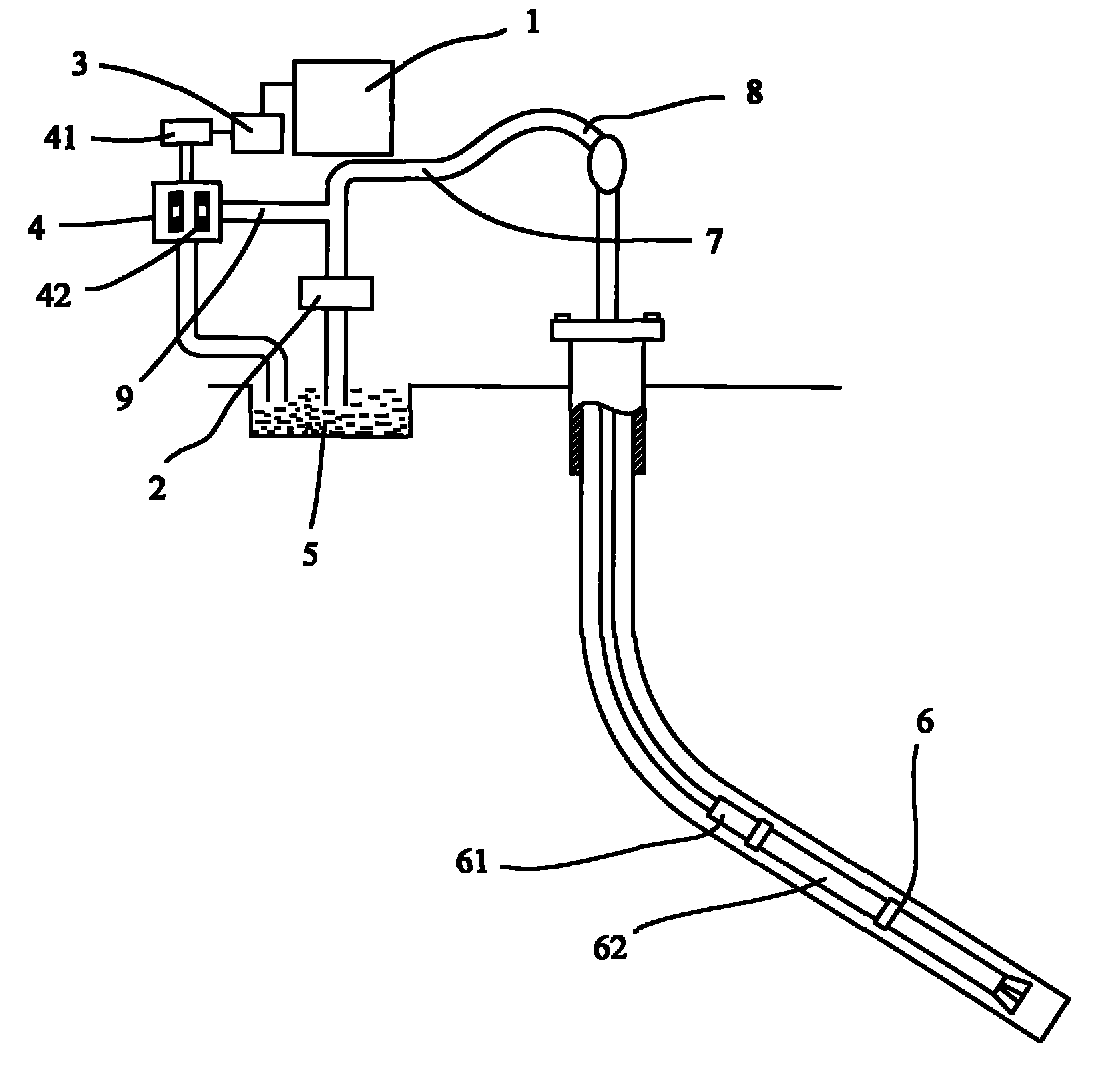

[0027] The present invention comprises the following steps:

[0028] (1) The ground control system sends ground control commands to the mud pump and command conversion unit;

[0029] (2) The mud pump is started under the control of the ground control system to pump mud to the rotary steerable drilling tool;

[0030] (3) The command conversion unit receives the ground control command sent by the ground control system, converts the command into a time flow change parameter, and sends it to the mud flow control valve;

[0031] (4) The mud flow control valve acts according to the time flow change parameter sent by the instruction conversion unit, and diverts the mud pumped by the mud pump in step (2);

[0032] (5) The command analysis unit in the rotary steerable drilling tool receives the diverted mud, and analyzes the ground control command according to the time flow change of the mud;

[0033] (6) The instruction analysis unit sends the analyzed surface control instruction to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com