Stepless speed changer

A technology of continuously variable transmission and speed change mechanism, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of complex structure, low power and troublesome control of the continuously variable transmission, so as to extend the mileage between overhauls. , high average speed, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

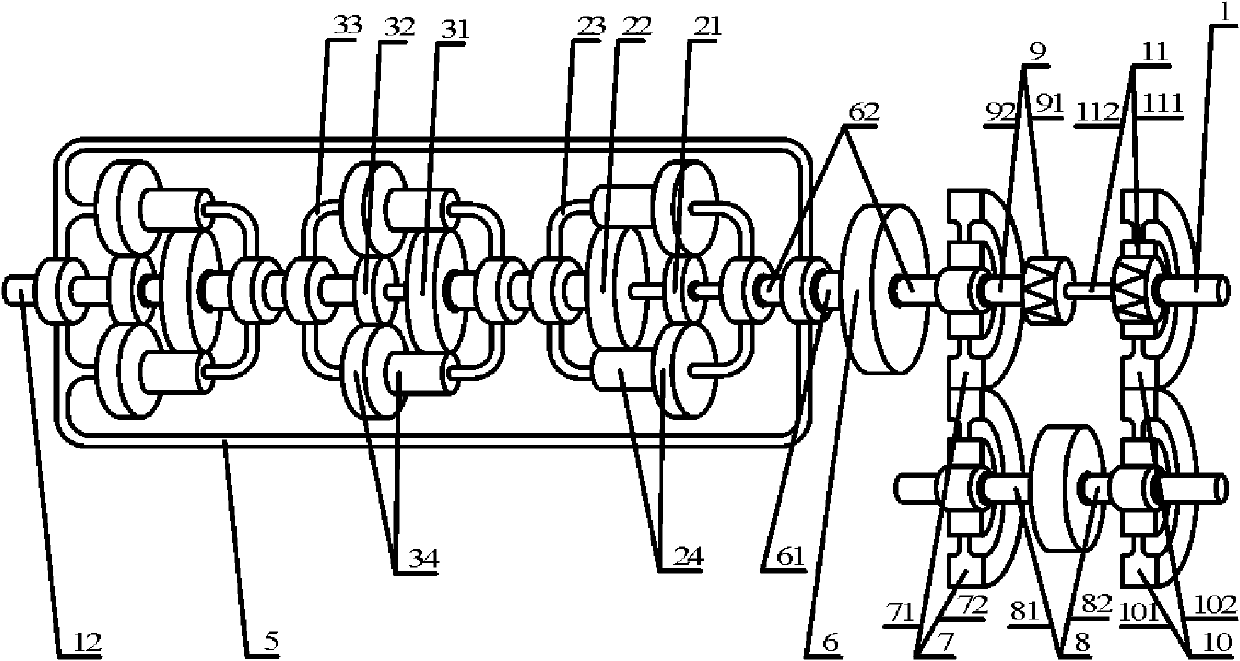

[0027] Such as figure 1As shown in , a continuously variable transmission includes an input shaft 1, a coupling frame 5, a transmission mechanism 6, an input gear pair 7, a coupling 8, a fixed one-way clutch 9, an output gear pair 10, a one-way clutch 11, an output shaft 12. The input end 91 of the fixed one-way clutch 9 is connected to a fixed element other than the present invention. Between the input shaft 1 and the output shaft 12, there are sequentially connected confluence units 2 composed of planetary rows and two The diversion unit 3, the diversion unit 2 includes the first diversion input element 21, the diversion output element 22, the second diversion input element 23, the diversion planetary gear 24, and the diversion unit 3 includes the diversion input element 31, the first The diversion output element 32, the second diversion output element 33, the diversion planetary gear 34, the confluence unit 2 is connected with the first confluence input element 21, the conf...

Embodiment 2

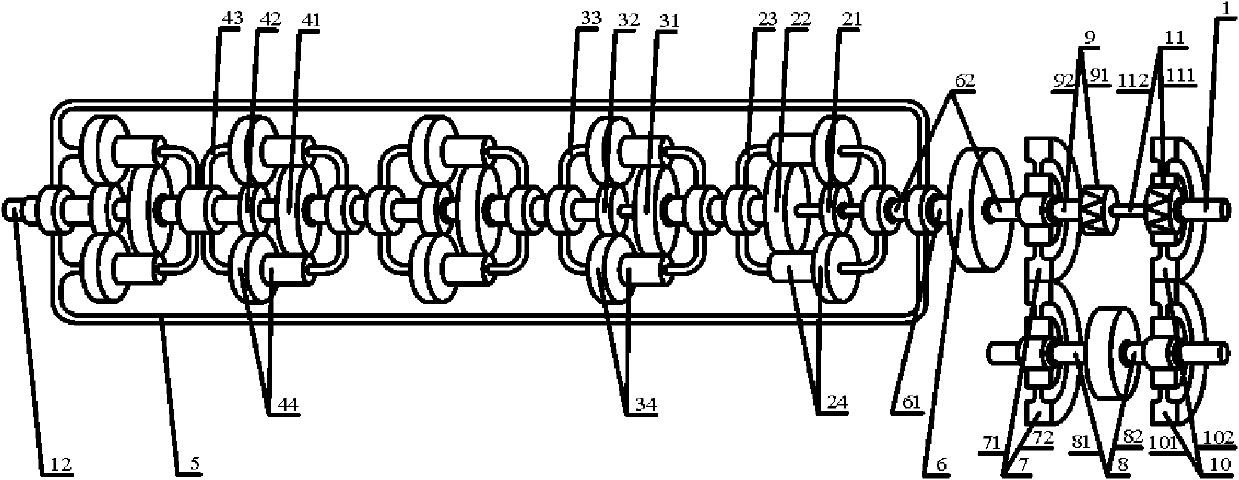

[0036] Such as figure 2 As shown in , it includes an input shaft 1, an output shaft 12, a transmission mechanism 6, an input gear pair 7, a torque converter 8, a fixed one-way clutch 9, an output gear pair 10, and a one-way clutch 11. The input end 91 of the clutch 9 is connected to a fixed element other than the present invention, and the input shaft 1 and the output shaft 12 are provided with a confluence unit 2 composed of a planetary row, two diversion units 3 and two The return unit 4, the return unit 4 includes a return input element 41, a first return output element 42, a second return output element 43, and a return planetary gear 44. The confluence unit 2 cooperates with the first reflow planetary gear 24 The confluence input element 21, the confluence output element 22, and the second confluence input element 23 are connected, the confluence output element 22 of the confluence unit 2 is connected with the diversion input element 31 of the first diversion unit 3, and...

Embodiment 3

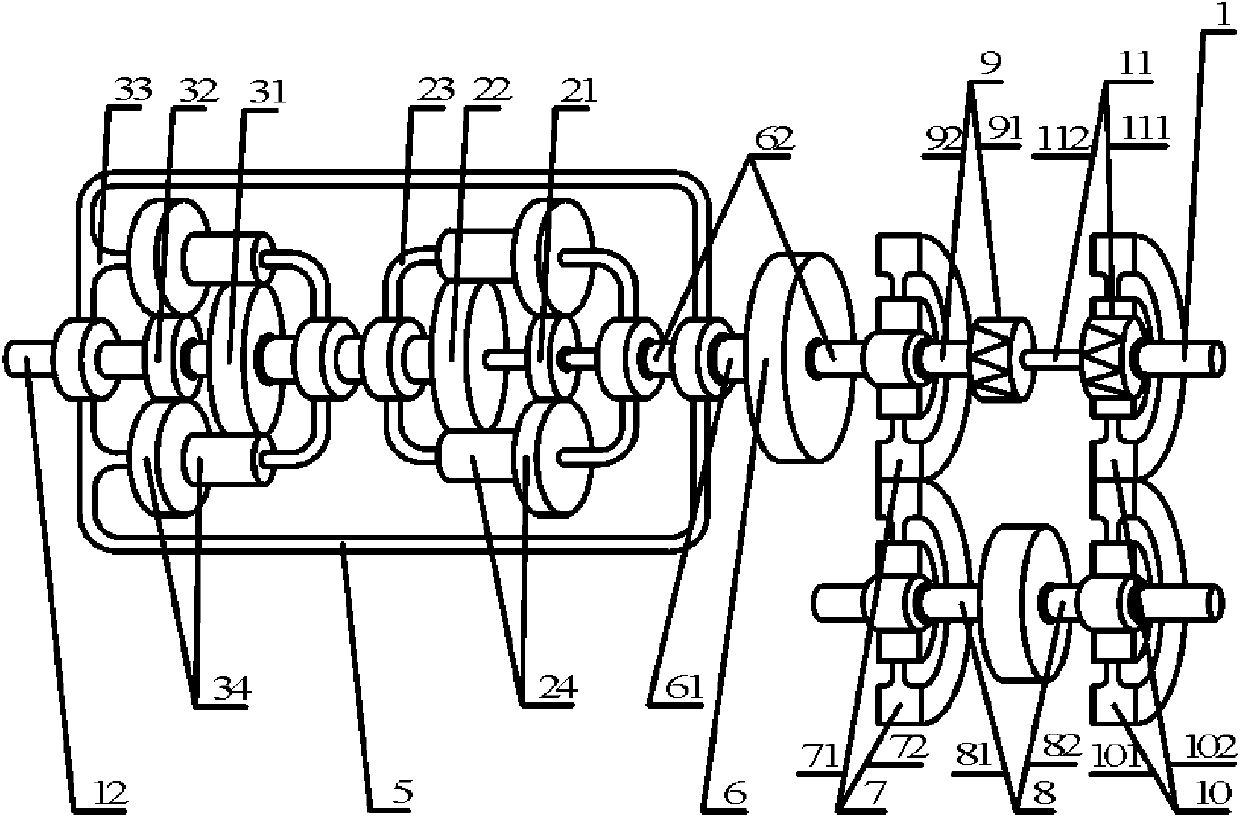

[0042] Such as image 3 As shown in , the present embodiment just replaces the two branching units 3 selected by the first embodiment with the same branching unit 3, and the branching input element 31 of this branching unit 3 is the branching input of each branching unit 3 of several branching units 3 Element 31, and is the branching input element 31 of first branching unit 3; The first branching output element 32 of this branching unit 3 is the first branching output element 32 of each branching unit 3 of several branching units 3; The first branching output element 32 of this branching unit 3 Two split flow output elements 33 are the second split flow output element 33 of each split flow unit 3 of several flow split units 3, and are the second split flow output element 33 of the last split flow unit 3, the connection object of each element replaced is the same as the original replaced one The connection object of each component remains unchanged, and its working principle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com