Defrosting control method for intelligent air cooling heat pump

A control method and intelligent wind technology, applied in the direction of refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of reducing the heating operation time of the unit, affecting the heating effect of the unit, and the influence of the heating effect, so as to achieve stable working temperature , shorten the defrosting time and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] After the unit starts running, detect the running time t of the compressor, the outdoor ambient temperature Ta, and the temperature Tc of the outdoor coil; the control parameters include: the unstable running time of the compressor t s , coil frosting temperature T s , Allowable frosting thickness temperature difference △T s ; Calculation parameters include: the difference between the outdoor ambient temperature and the outdoor coil temperature △T, the initial frosting temperature difference of the coil △T 0 .

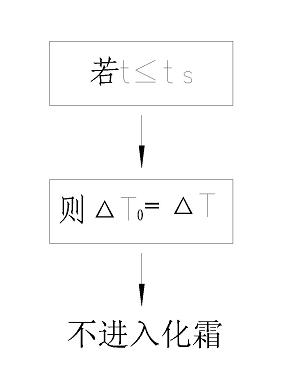

[0022] (1) if figure 1 As shown, when t≤t s , then △T 0 =△T, the system does not enter defrosting;

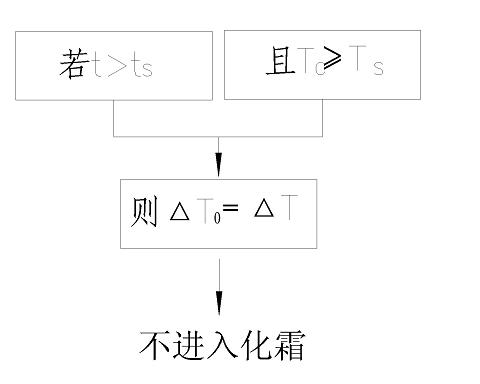

[0023] (2) if figure 2 As shown, when t>t s , and Tc≥T s , then △T 0 =△T, the system does not enter defrosting;

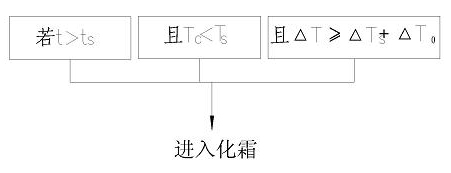

[0024] (3) if image 3 As shown, when t>t s , and Tcs , △T≥△T s +△T 0 , the system enters defrosting.

[0025] The above control logic is aimed at the characteristics that condensed water is generated on the surface of the outdoor hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com