Command sequence-based method for displaying processing state information of digital control machine tool

A processing state and instruction sequence technology, applied in the field of numerical control, can solve the problems of small surface defects, difficult analysis and diagnosis of processing conditions, and inconvenient processing, and achieves high real-time performance, simple and clear observation, and comprehensive information and data acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

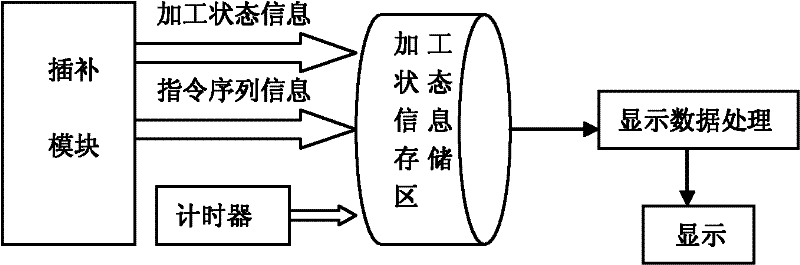

[0021] Such as figure 1 As shown, a method for displaying processing status information of CNC machine tools based on instruction sequences provided by the present invention includes the following steps:

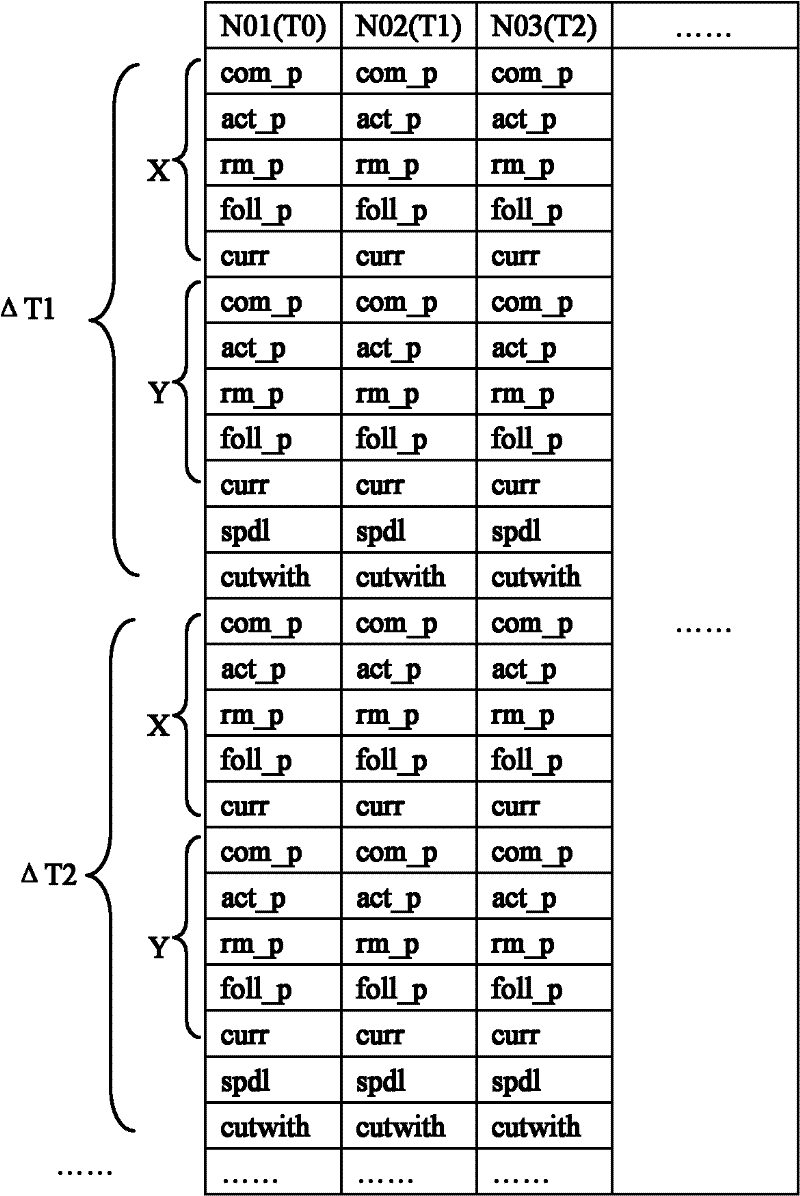

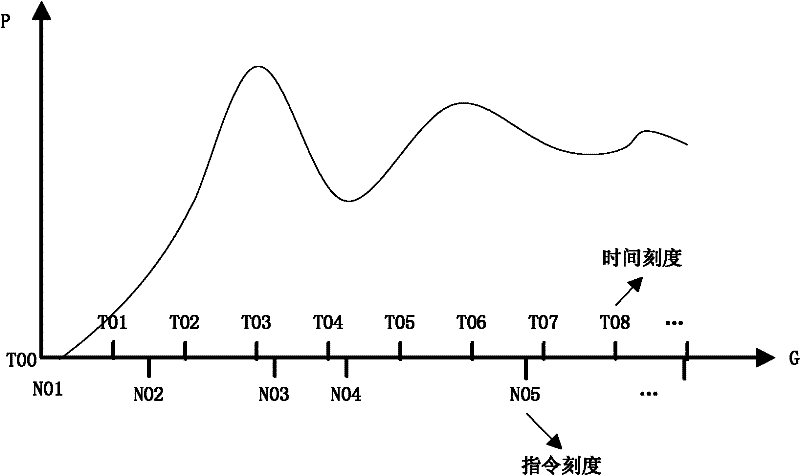

[0022] Step 1: During the operation of the CNC system, obtain various processing status information and instruction sequence information for each interpolation cycle, and use the executed program segment number as the group index, and each group contains the information obtained during the execution of the program segment In the group, the processing status information obtained by each interpolation cycle is used as a group, and one interpolation cycle corresponds to a group, and each group arranges the processing status information in the order of the axis number. This record and save the processing status information to the storage area. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com