Scuffing detection

A cylinder and two-stroke technology, which is applied in the field of detection of wear in large two-stroke diesel engines, can solve the problems of expensive countermeasures, expensive cylinder lubricating oil, power reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

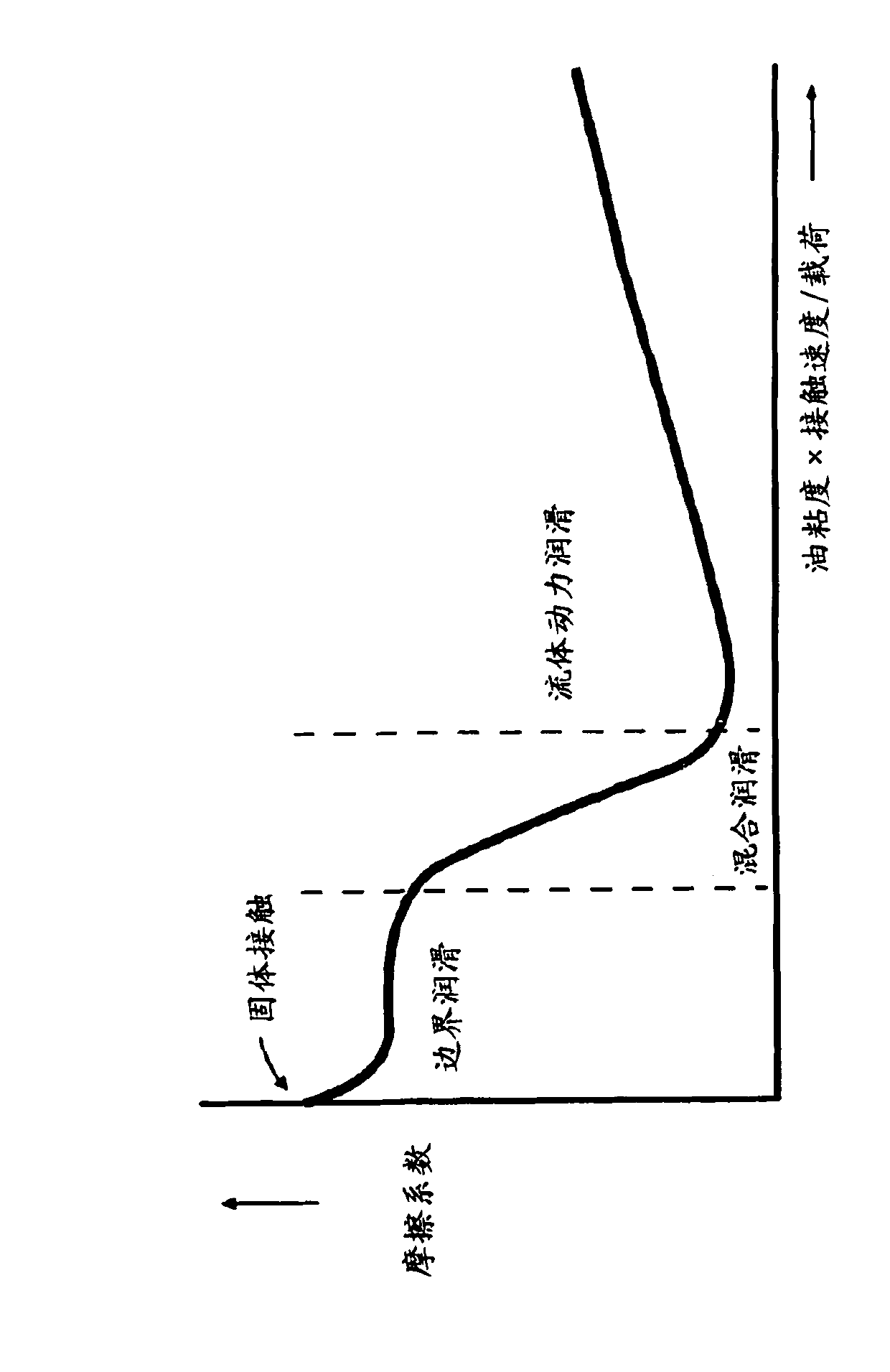

[0034] figure 1 The so-called Stribeck curve is shown. Piston ring and liner surfaces experience all three wear mechanisms as described by this curve, which relates (viscosity, load, velocity) to the coefficient of friction. The three mechanisms are boundary lubrication, mixed lubrication, and hydrodynamic lubrication. Hydrodynamic lubrication is the condition where surfaces are completely separated by an oil film. If the load is carried only partly by oil film pressure and partly by contact with asperities, the condition is called mixed lubrication. If the entire load is carried by the asperity and the only separation is a thin molecular oil film, then the condition is called boundary lubrication.

[0035] In large two-stroke diesel engines, boundary lubrication always exists to a lesser extent around top dead center (TDC), where the speed of the piston approaches zero. Where bore grinding is taking place, the amount of boundary lubrication will rise to the point where we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com