Organized wiredrawing protein and preparation method thereof

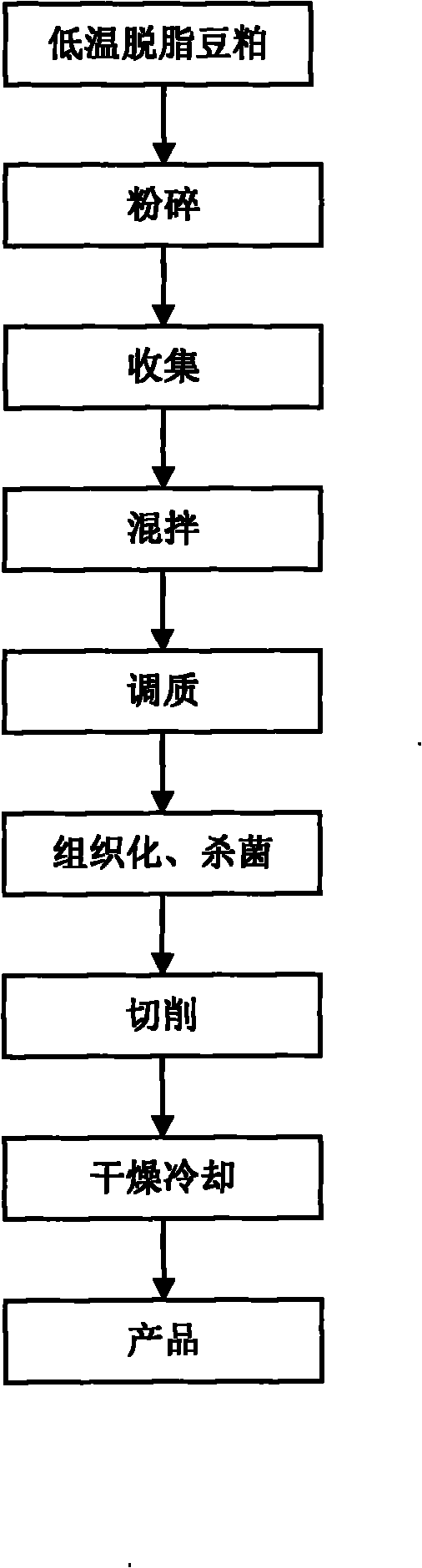

A technology for drawing protein and separating protein, applied in the direction of texturization, vegetable protein processing, etc., can solve the problems of low protein content, single protein source, immature taste and appearance, etc., and achieve the effect of ensuring color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

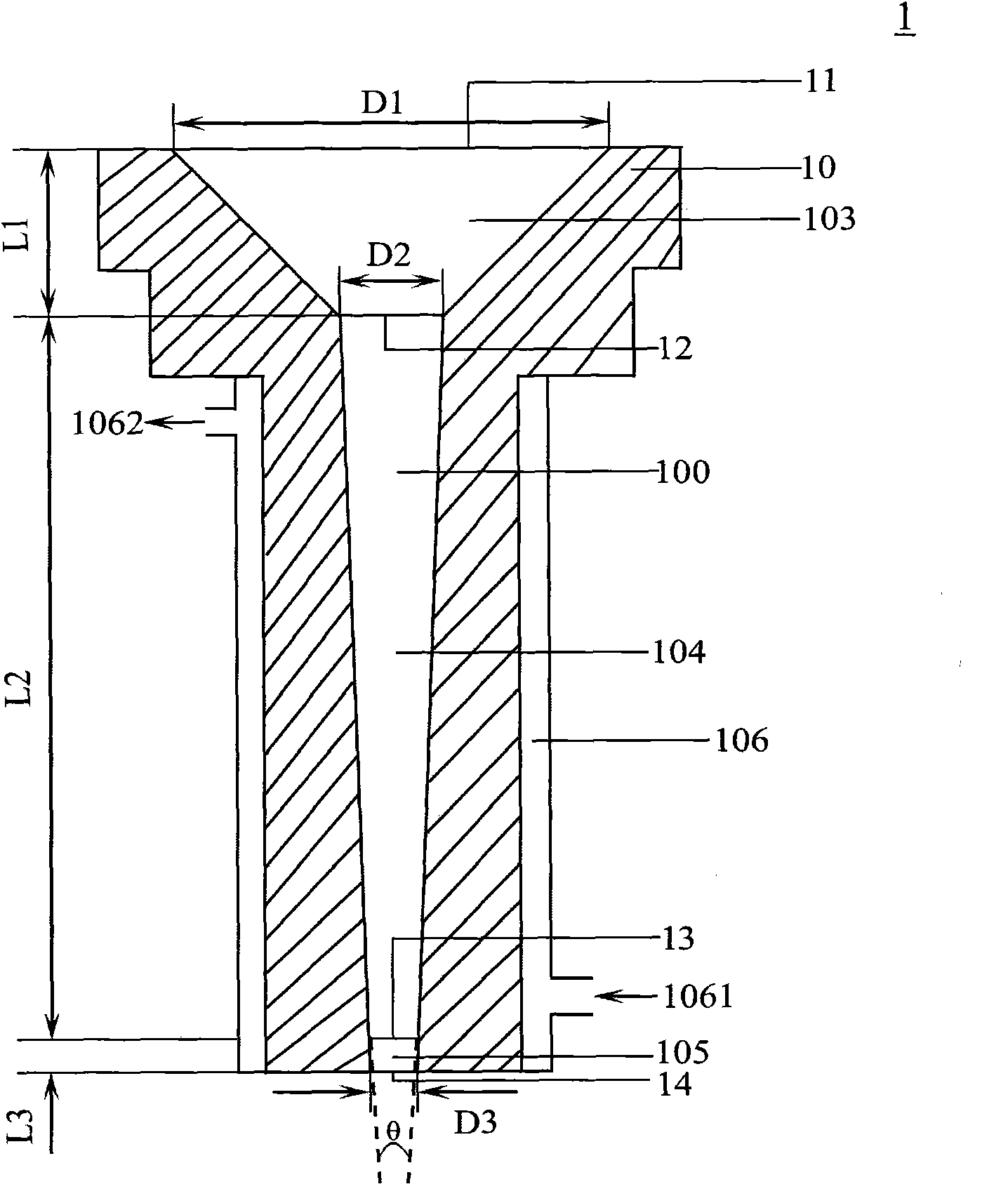

[0046] Preparation example 1: Preparation of wire drawing export mold (die 1):

[0047] In one embodiment of the structure of the self-made wire drawing outlet die of the company described in the present invention, the structure of the wire drawing outlet die 1 of the extrusion extruder is as follows: the mold cone cavity 103 is connected to a cylindrical cavity 105 in sequence, wherein the cone cavity The diameter D1 of the upper edge 11 of 103 matches the outlet of the extruder, the length L1 of the cone cavity 103 is 740mm, and the lower edge 12 (diameter D2) of the cone cavity 103 is connected to the upper edge 13 of the cylindrical cavity 105 (diameter D3), the diameter D3 of described cylindrical cavity 105 is 12mm, the length L3 of described cylindrical cavity 105 is 5mm, the upper edge of described cylindrical cavity 105 is 13, the lower edge is 14, the upper edge 13 and the lower edge 14 The diameter is D3.

preparation example 2

[0048] Preparation example 2: Preparation of wire drawing export mold (die 2):

[0049]In one embodiment of the structure of the self-made wire drawing outlet die of the company described in the present invention, the structure of the wire drawing outlet die 2 of the extrusion extruder is as follows: the mold has two continuous cone cavities 103, 104 and a cylindrical cavity 105 are connected in sequence, wherein the diameter D1 of the upper edge 11 of the cone cavity (first cone cavity) 103 with a larger diameter matches the outlet of the extruder, and the length L1 of the cone cavity 103 with a larger diameter is 50 mm. The lower edge 12 (diameter D2) of the larger cone cavity 103 of the diameter is connected to the upper edge 12 (diameter D2) of the smaller cone cavity (second cone cavity) 104, the smaller cone cavity 104 of the diameter The cone angle θ is 4°, the length L2 of the smaller diameter cone cavity 104 is 800 mm, the lower edge 13 of the smaller diameter cone ca...

preparation example 3

[0051] Preparation example 3: Preparation of wire drawing export mold (die 3):

[0052] Such as image 3 As shown, the specific dimensions are:

[0053] D1: match with the outlet of twin-screw extrusion extruder;

[0054] D3: 10mm;

[0055] L1: 50mm;

[0056] L2: 600mm;

[0057] L3: 15mm;

[0058] θ: 5°;

[0059] In addition, a sheath 106 with a liquid inlet 1061 and a liquid outlet 1062 is provided on the outer periphery of the smaller diameter cone cavity 104 and cylindrical cavity 105 of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com