Rice production line

A production line and rice technology, which is applied in the field of kitchen equipment, can solve the problems of high failure rate, lack of practicability, insufficient to meet application needs, etc., and achieves the effect of improving coordination, good practicability, and reducing human operation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the rice production line of the present invention will be described below with reference to the accompanying drawings.

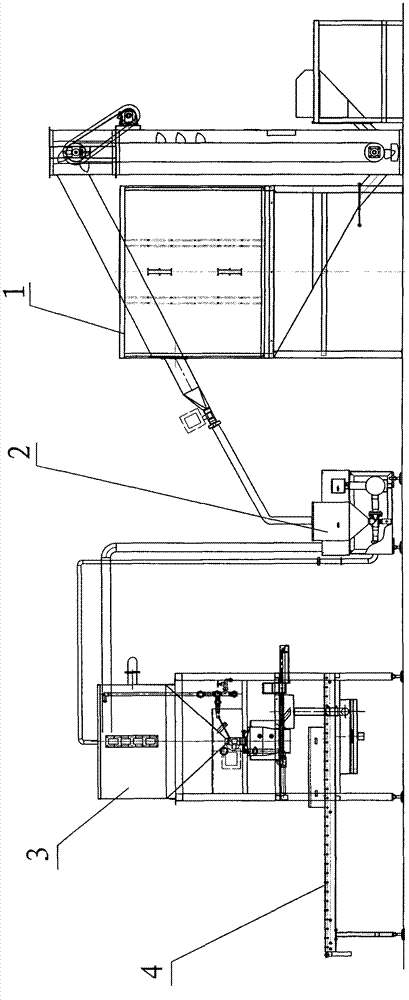

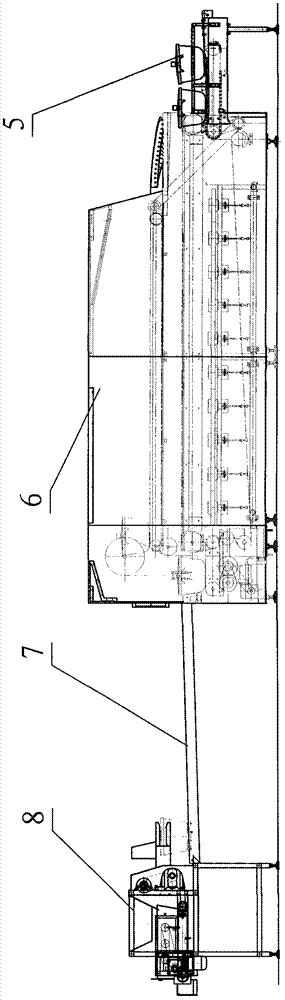

[0027] Such as figure 1 and figure 2 As shown, the rice production line of the present invention includes a rice storage bin 1, a rice washing machine 2, a metering filling machine 3, a first unpowered track 4, a cooking and stewing machine 6, a second unpowered raceway 7, and a turning and loosening machine connected in sequence. Machine 8.

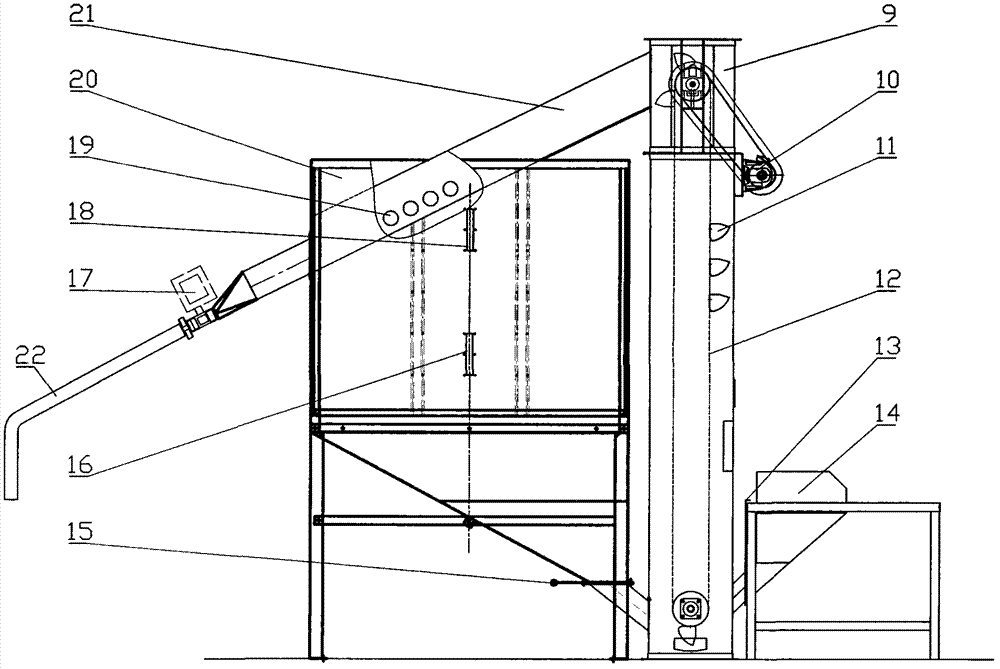

[0028] see image 3The above-mentioned rice storehouse 1 includes a rice bucket 14, a rice warehouse 20, a rice lifter 9, a rice chute 21 and a quantitative pump 17, and the rice bucket 14 and the rice warehouse 20 respectively pass through the first manual gate 13 and the second The manual gate 15 is in operative communication with the rice extractor 9 . By the operation of the first manual gate 13 and the second manual gate 15, rice can enter the rice extractor 9 from the rice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com