Safety electric pressure cooker

A technology for safe voltage and force cookers, applied in pressure cookers, cooking utensils, household utensils, etc., can solve the problems of welding process cost, poor safety, unreliable welding, etc., to achieve simple manufacturing process, reduced material consumption, The effect of fast cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

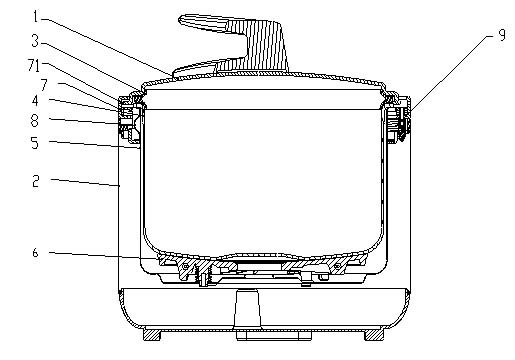

[0025] Such as figure 1 , figure 2 , Figure 4 As shown, this embodiment includes a switch 9 connected to the control circuit, an outer pot 5, an inner pot 4 that can be accommodated in the outer pot 5, a pot lid 1 with lid teeth that is fastened on the outer pot 5 and placed The heating device 6 on the bottom surface of the outer pot 5, wherein the outer pot 5 is a thin-walled structure with a pot wall thickness not greater than 0.5 mm, and the above-mentioned switch 9 connected with the control circuit is arranged below the edge of the outer pot 5. The outer pot 5 is fixedly connected with buckle teeth 7 along the outer wall. The main body of the buckle teeth 7 is a ring structure, and its lower end is screwed to the upper part of the outer pot 5. The main body of the buckle teeth 7 is evenly distributed with pot teeth corresponding to the lid teeth of the pot cover 1. , The pot teeth are arranged on the button teeth 7 and are screwed to the other end of the outer pot. I...

Embodiment 2

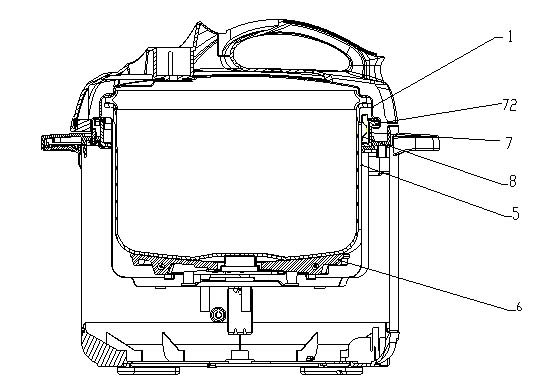

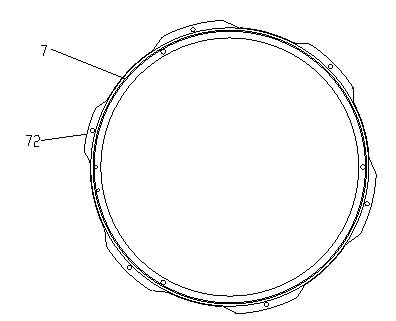

[0030] The difference from the first embodiment is the same, such as figure 2 , image 3 As shown, the pot tooth on the main body of the button tooth 7 in the present embodiment forms a boss structure 72, corresponding to this, the pot cover 1 covers the groove structure of the inner buckle, and the pot cover 1 is buckled by its cover tooth. The groove structure is fastened on the boss structure 72 of the pot tooth and connected with the outer pot 5, that is, the connection between the pot cover 1 and the outer pot 5 adopts an external rotation connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com