Printing paper seasoning apparatus, method therefor and inkjet recording apparatus

A printing paper and adjustment device technology, applied in the direction of printing devices, printing, stacking receiving devices, etc., can solve the problems of size and position deviation, overprint mismatch, air flow deterioration, etc., to prevent expansion/shrinkage and deformation paper, preventing misalignment of overprinting, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0068]

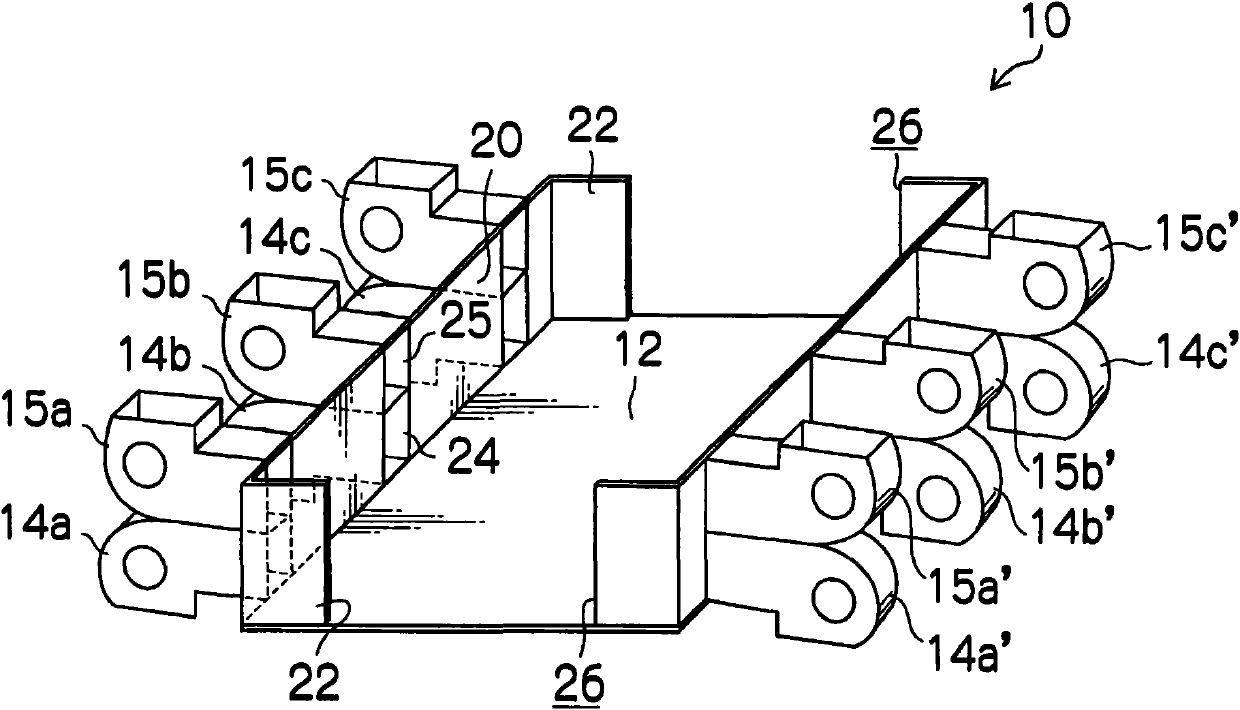

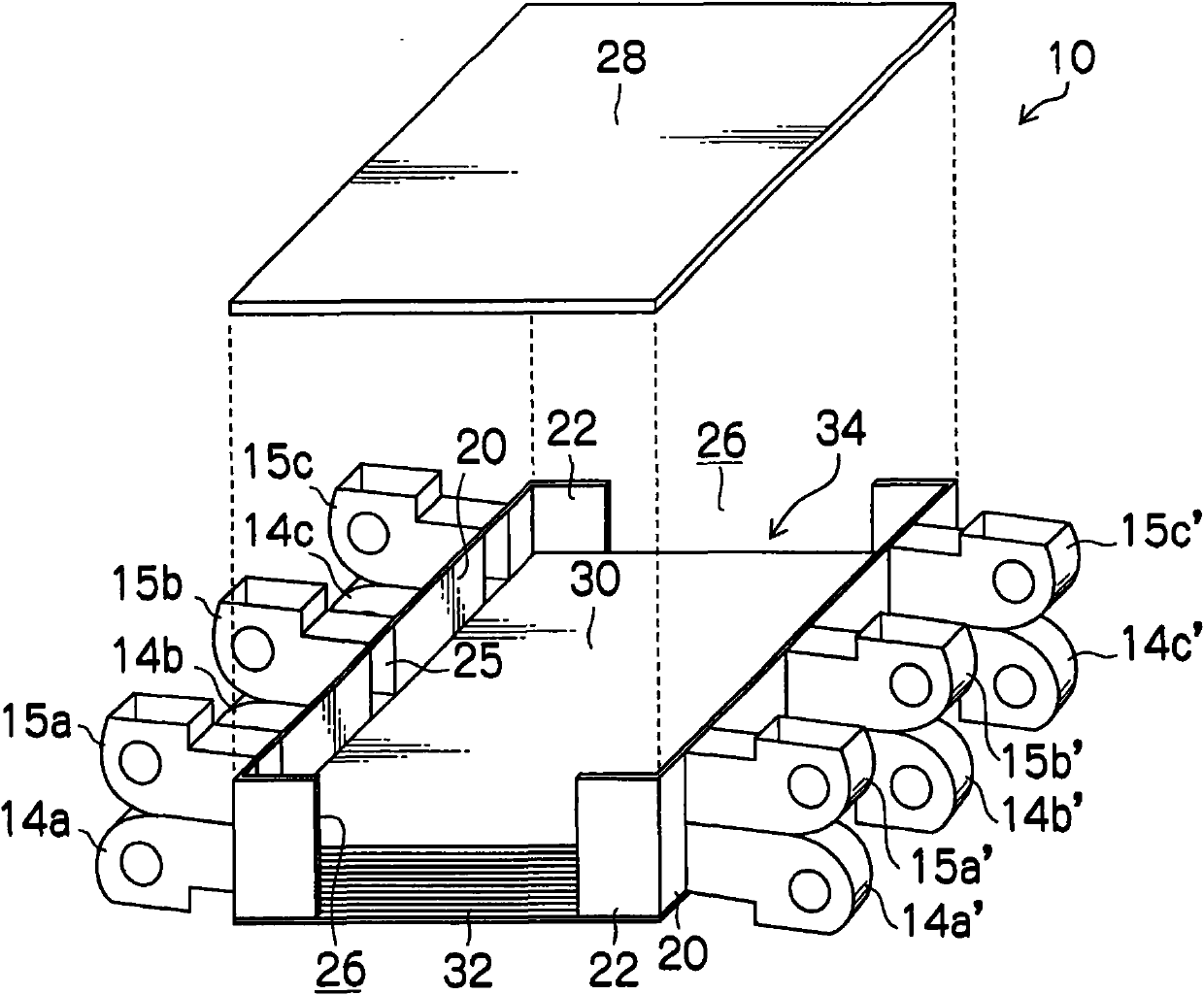

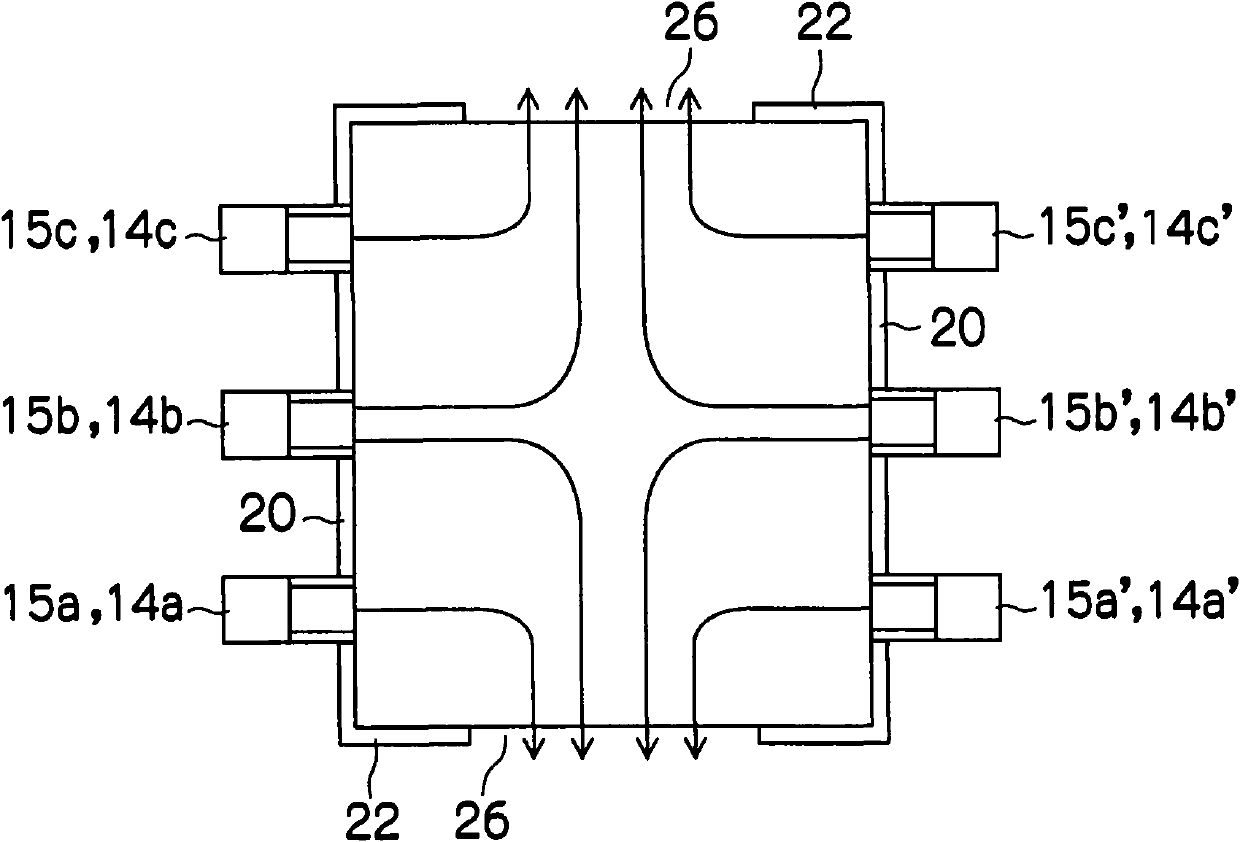

[0069] figure 1 is a perspective view of an adjustment device according to a first embodiment of the present invention. as shown in figure 1 , the adjusting device 10 includes: a loading platform 12 on which a plurality of printing paper 30 (not shown in figure 1 , but shown in figure 2 ; hereinafter referred to as "paper") can be stacked; On the outer peripheral side of the paper stack placed on the stage 12 .

[0070] Hereinafter, for simplicity of description, the lower-stage blowers 14 a to 14 c and 14 a ′ to 14 c ′ may be referred to as blowers 14 , and the upper-stage blowers 15 a to 15 c and 15 a ′ to 15 c ′ may be referred to as blowers 15 . figure 1 The blowers 14 and 15 in are shown as axial flow blowers; however, the blowing method is not particularly limited, and a centrifugal blower can also be used.

[0071] The conditioning device 10 in the present embodiment has a configuration in which air is blown toward the paper stack to both side end faces...

no. 2 approach

[0108] Figure 7 is a schematic diagram of main parts of an adjustment device according to a second embodiment of the present invention. exist Figure 7 in, with Figures 1 to 4C The same or similar elements in the configuration described in are given the same reference numerals, and their description will not be repeated. in reference to Figures 1 to 6 In the described first embodiment, the means for changing and controlling the air volume difference in the vertical direction controls the output of each of the upper-stage blower 15 and the lower-stage blower 14 . It is also possible to use wind guides 60 instead of or in combination with such devices, as shown in Figure 7 . Here, only the parts corresponding to the blowers 14a' and 15a' are depicted, and similar wind guides 60 are respectively equipped for the other blower units (14a and 15a, 14b and 15b, 14c and 15c, 14b' and 15b', and 14c' and 15c').

[0109] The wind guide 60 is arranged in the substantially centr...

no. 3 approach

[0115] Figure 9 is a schematic diagram of main parts of an adjustment device according to a third embodiment of the present invention. Figure 9 The illustrated embodiment is provided with gates 71 a , 71 b , 72 c , 71 d , 72 a , 72 b , 72 c and 72 d as means of varying the sealing ratio of the side panels 20 . arranged in the figure 1 The side panels 20 at the positions where the sides of the sheets of paper 30 face each other have the same structure.

[0116] Figures 10A to 10C yes Figure 9 A schematic view of the side panel 20 as seen from above is shown. exist Figures 10A to 10C , only the upper level gates 72a to 72d are depicted, but the lower level gates 71a to 71d (see Figure 9 ) has a similar configuration. Opening 73 (see Figures 10A to 10C ) are formed in the side plate 20 at positions corresponding to the gates 71a to 71d and 72a to 72d.

[0117] Figure 10A A state in which the shutters 72a to 72d are fully opened is shown (the sealing rate of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com