Decorated panel and connecting structure thereof

A technology for connecting structures and decorative panels, applied in the field of building decoration materials, can solve the problems of difficulty in rapid heat transfer, complex manufacturing processes, long heat conduction paths, etc., and achieve the effects of short heat conduction paths, good thermal stability, and high heat conduction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

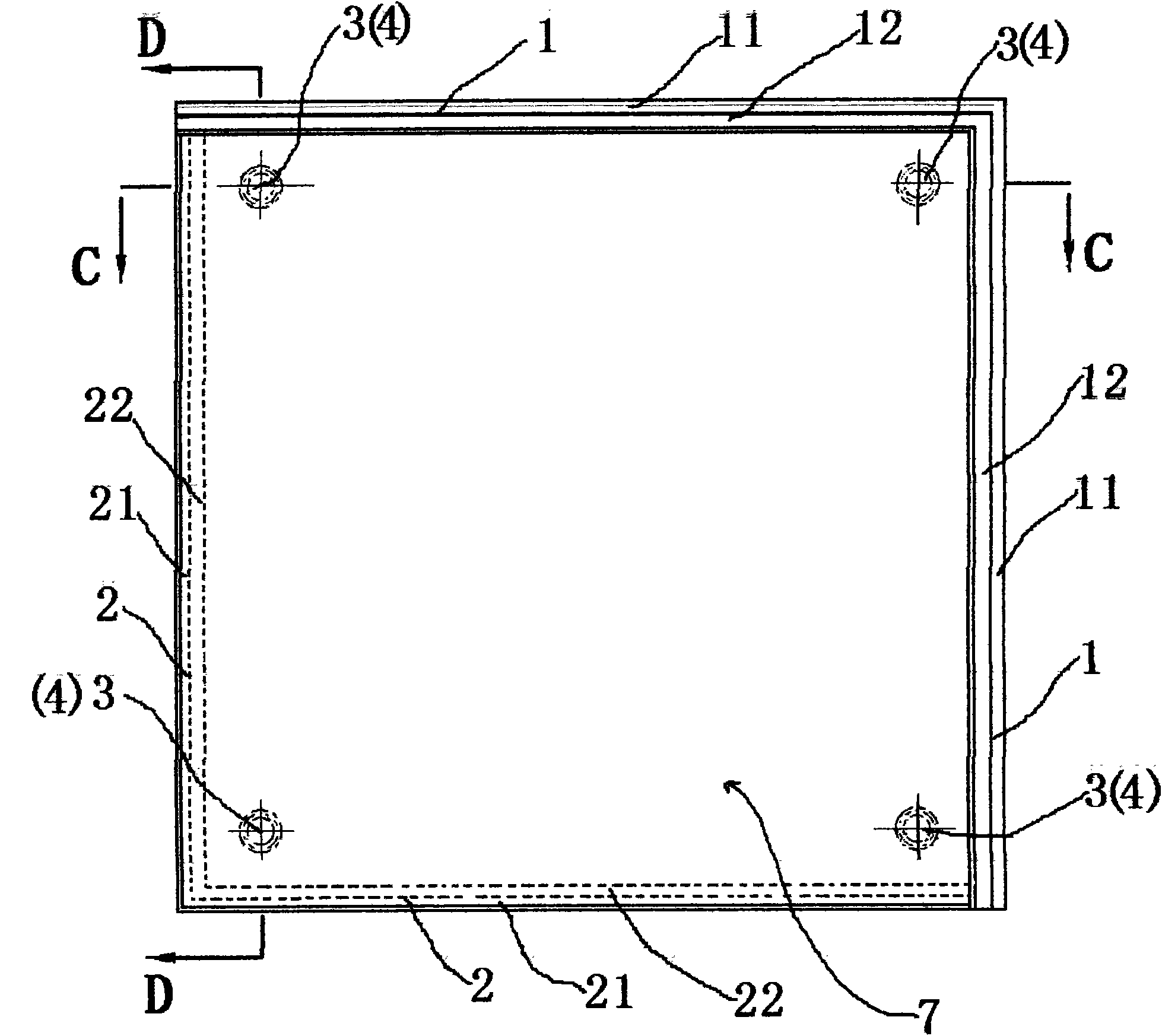

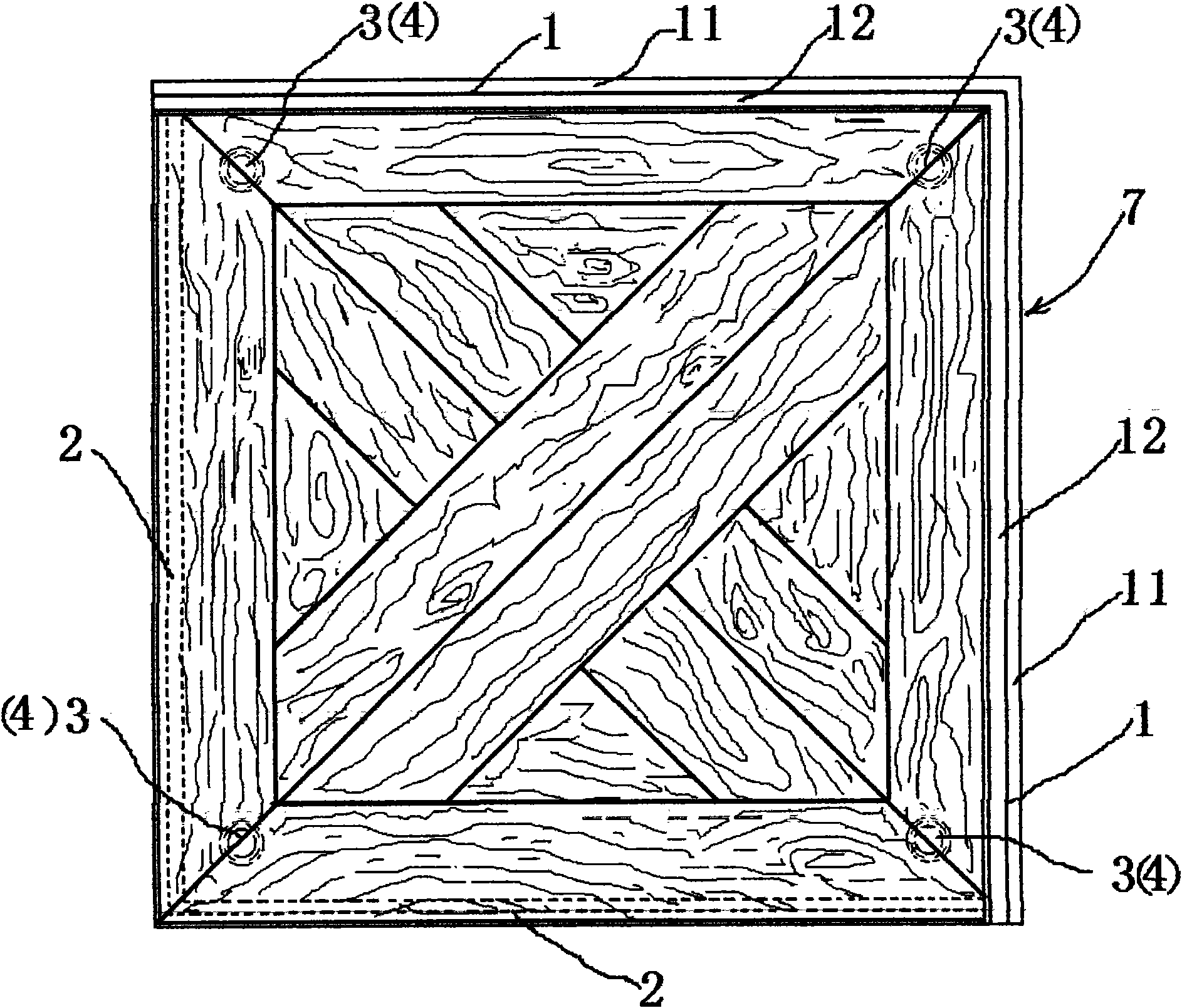

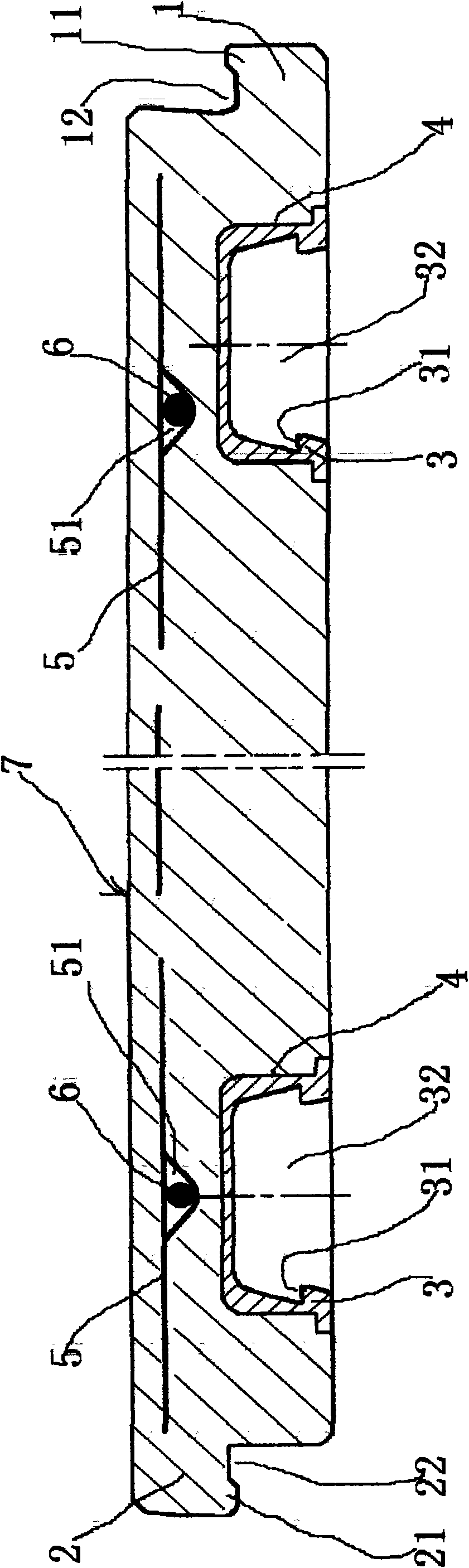

[0033] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 or Figure 5 As shown, a veneer (7) includes a veneer (7) body, the veneer (7) body has an overall square plate-like structure, and the veneer (7) consists of four sides connected end to end, wherein two adjacent A first tongue-and-groove structure (1) extending from the lower bottom of the veneer (7) is arranged on the same side, and the length of the first tenon-groove structure (1) is equal to the lower edge of the veneer (7). The tongue-and-groove structure (1) includes a first tenon body (11) and a first groove body (12), and the other two adjacent sides are also provided with a second tenon extending from the upper surface of the veneer (7) Groove structure (2), the length of the second mortise and groove structure (2) is equal to the upper edge of the veneer (7), and the second mortise and groove structure (2) includes a second tenon body (21) and a second groove body ( 22), the first tenon body (1...

Embodiment 2

[0034] Embodiment 2: as Image 6 , Figure 7 , Figure 8 , Figure 9 or Figure 10 As shown, a connection structure of veneer panels (7), including adjacent first veneer panels (71), second veneer panels (72), third veneer panels (73), fourth veneer panels (74) and common The independent coupling elements (8) connecting them are designed so that the adjacent veneer panels (7) are connected not only by the first tongue-and-groove structure (1) and the second tongue-and-groove structure (2) engaging with each other to form a snap connection but also The common coupling connection of the adjacent first veneer (71), second veneer (72), third veneer (73) and fourth veneer (74) is realized by independent coupling elements (8), wherein the first The first tongue-and-groove structure (1) in the first decorative panel (71) and the second tongue-and-groove structure (2) in the second decorative panel (72) are engaged with each other to form a snap connection. The second tongue and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com