Scraper cleaning type chute segregation distributor and segregation distributing device

A technology of distributor and scraper, which is applied in the field of scraper cleaning chute segregation distributor and segregation distribution device, which can solve the problems of unstable sinter quality in sintering machine production efficiency, weakened elasticity of linear components, and influence on segregation distribution effect, etc. , to achieve the effect of stabilizing the panel fabric, reducing frictional resistance, and facilitating installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

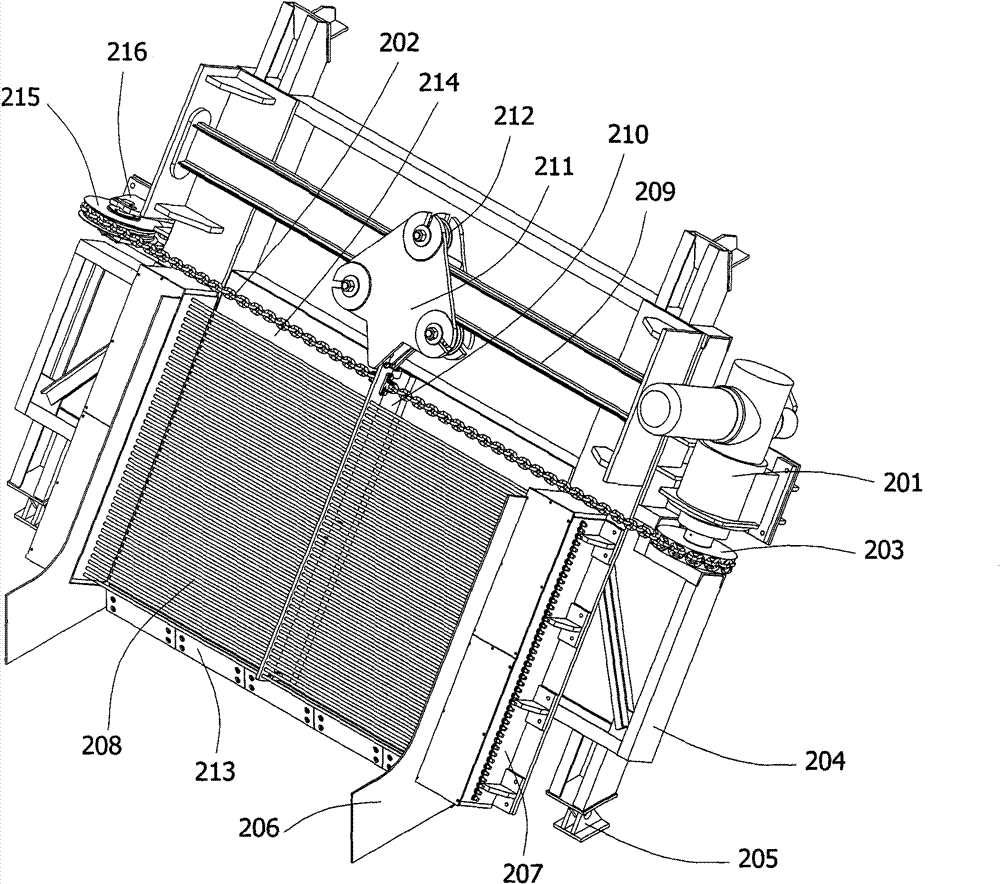

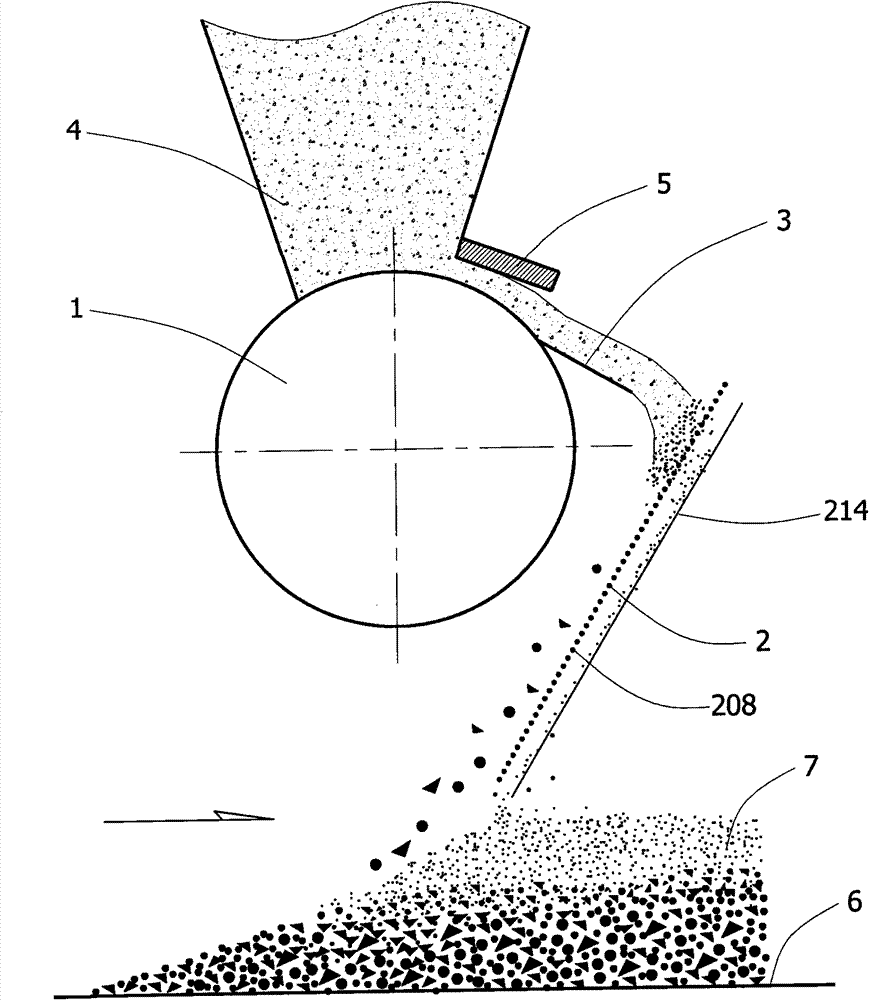

[0035] Example 2: Such as figure 2 As shown, the segregation cloth device of the present invention includes a feeding bin 4 and a round roller feeder 1. The round roller feeder 1 is arranged below the feeding bin 4, and the discharge end of the round roller feeder 1 is provided with For the scraper-cleaning chute segregation distributor 2 described in Example 1, the discharge end of the round roller feeder 1 is also provided with a control gate 5 and can improve the mixture 7 on the scraper-cleaning chute segregation distributor 2 Point the mixture guide plate 3. When the segregation cloth device of the present invention is working, the control gate 5 is opened, and the mixed material 7 is pulled out from the feeding bin 4 through the round roller feeder 1, and the mixed material 7 is dropped to the scraper through the mixed material guide plate 3 for cleaning On the type chute segregation distributor 2, the mixture guide plate 3 can extend the sliding stroke of the mixture 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com