Printed circuit board, method and device for detecting layer-to-layer registration of circuit graphs at two surfaces thereof

A circuit pattern and alignment technology, which is applied in the direction of measuring devices, printed circuits, printed circuit manufacturing, etc., can solve the problem that the core board is difficult to see the misalignment inspection ring, and detect whether the alignment between the circuit graphics layers on both sides of the core board is Meet the requirements and other issues to achieve the effect of improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

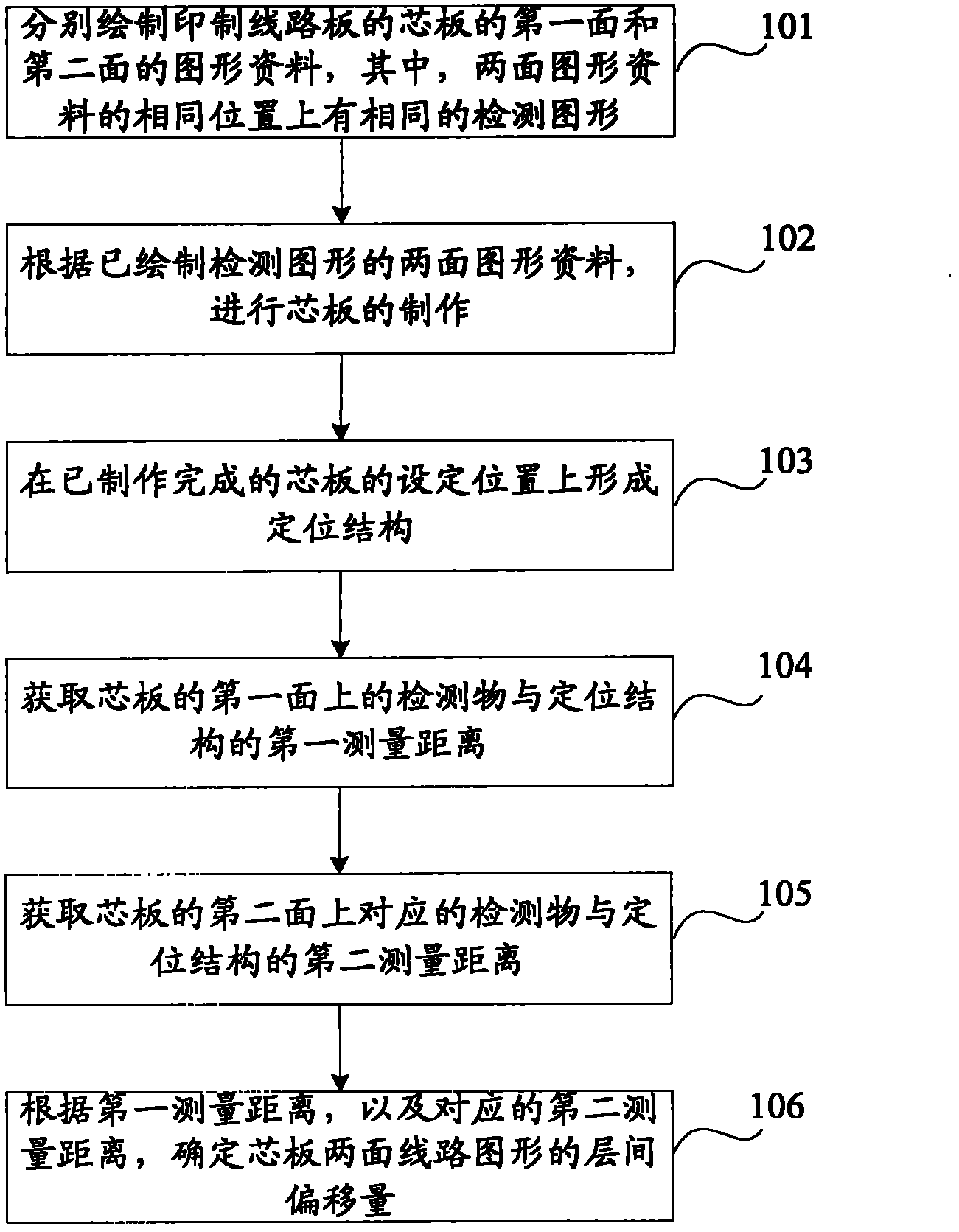

[0066] Embodiment 1. In this embodiment, the core board of the printed circuit board includes a double-sided circuit pattern. The shape of the core board is a regular rectangle. There is only one detection pattern on the graphic data of each side of the core board, and the detection pattern is circle, in this embodiment, the process of detecting the interlayer alignment of the circuit patterns on both sides of the printed circuit board is as follows: Figure 4 shown, including:

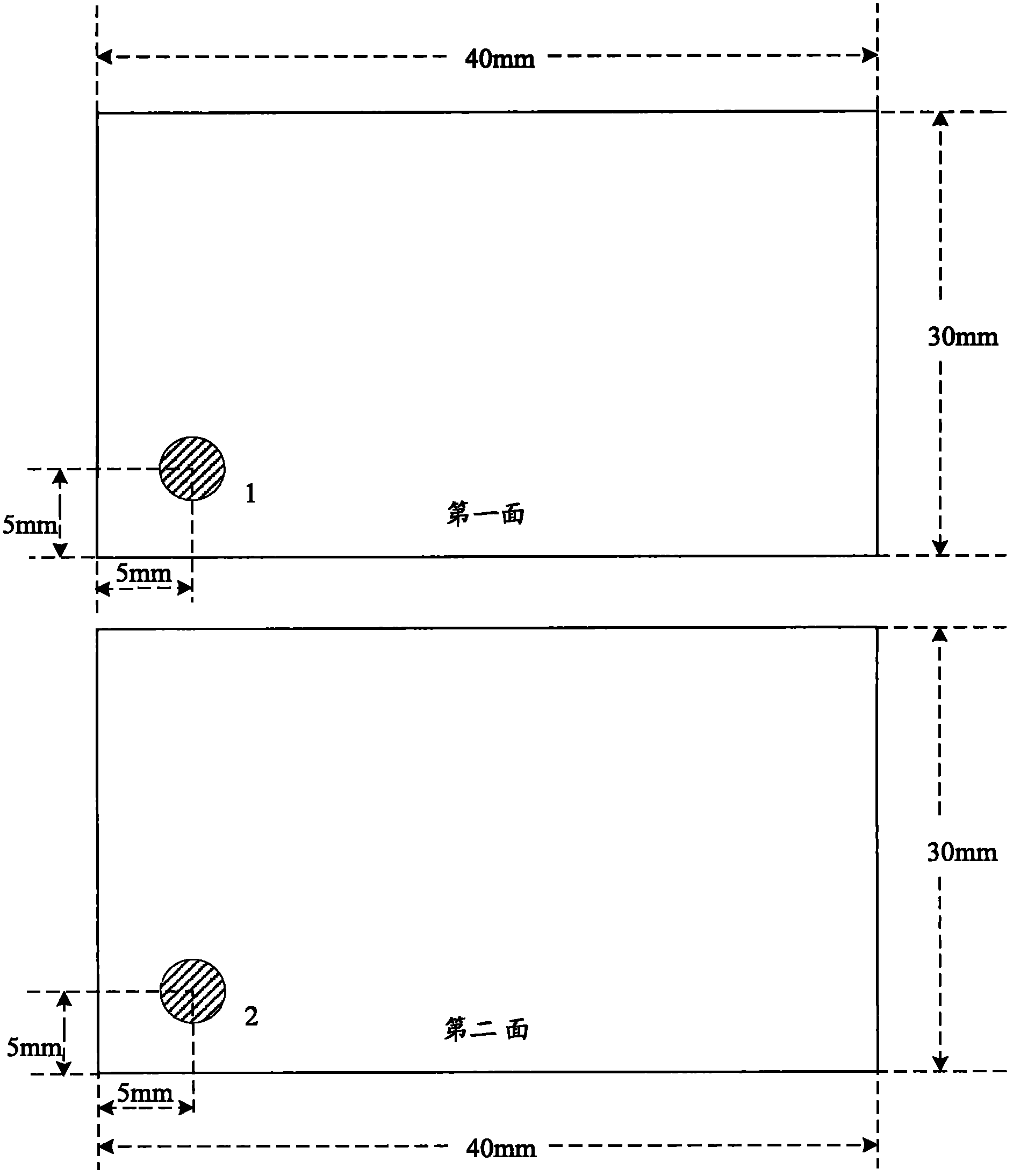

[0067] Step 401: Draw a circle with a set size at the same position on the upper left corner of the graphic data on both sides of the core board of the printed circuit board.

[0068] In this embodiment, the graphics data of the designed core board are as follows: Figure 5 As shown, there is a circle 1 with a diameter of 4.0mm in the upper left corner of the graphic data on the first surface, and the center origin of the circle 1 is 6.0mm and 4.0mm from the left side and the top side of the first su...

Embodiment 2

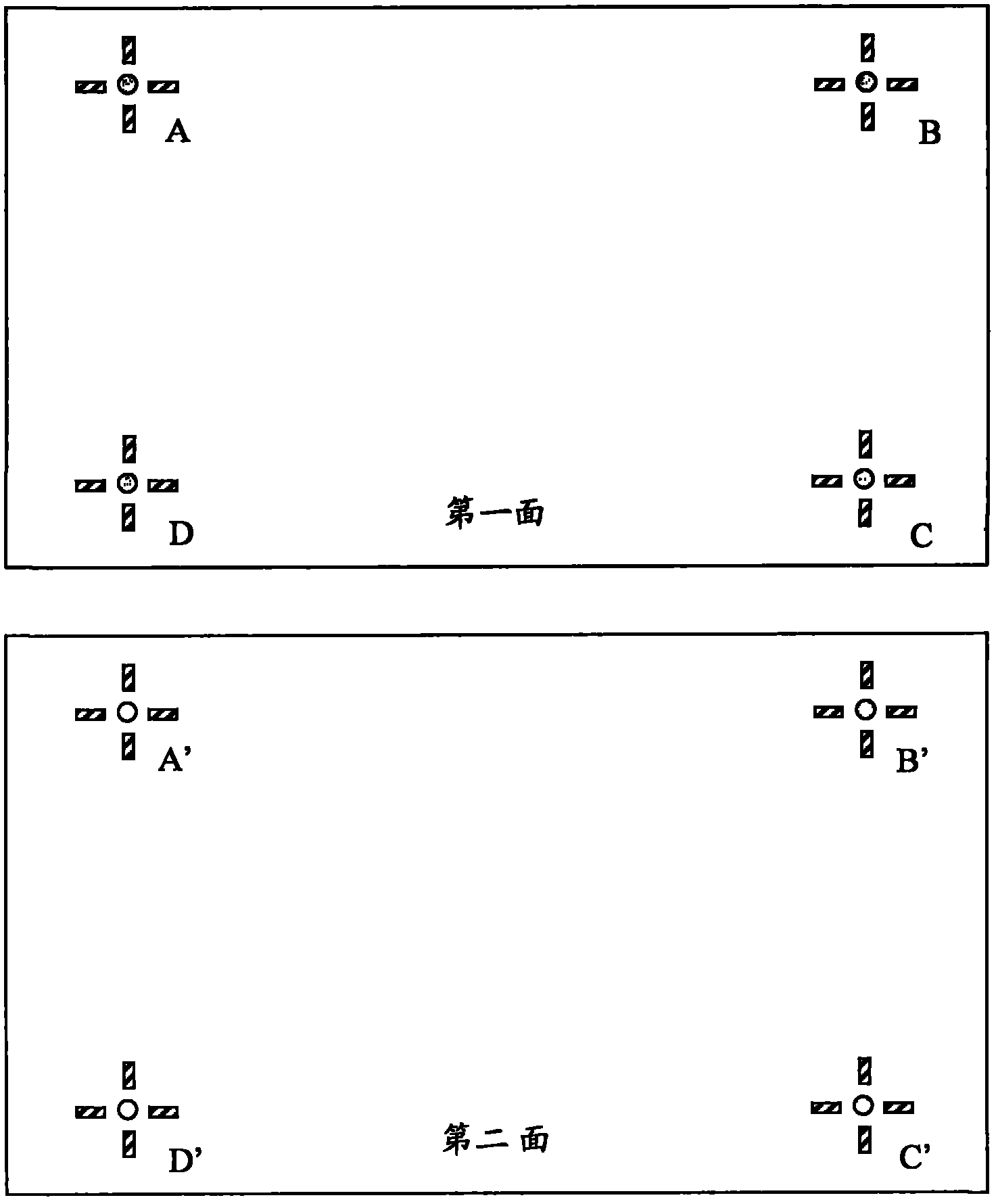

[0082] Embodiment two, in the present embodiment, core plate comprises double-sided circuit pattern, and the profile of core plate is an irregular quadrilateral, and there are four detection patterns on the figure data of every side, and each detection pattern is target disk shape, Then in this embodiment, the process of detecting the interlayer alignment of the circuit patterns on both sides of the core board is as follows: Figure 7 shown, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com