Light irradiation apparatus

A technology for a light irradiation device and a bonding device, which is applied to lighting devices, lighting device parts, optics, etc., can solve the problems of low device reliability and low energy efficiency, and achieve high reliability, high energy efficiency, and realization The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

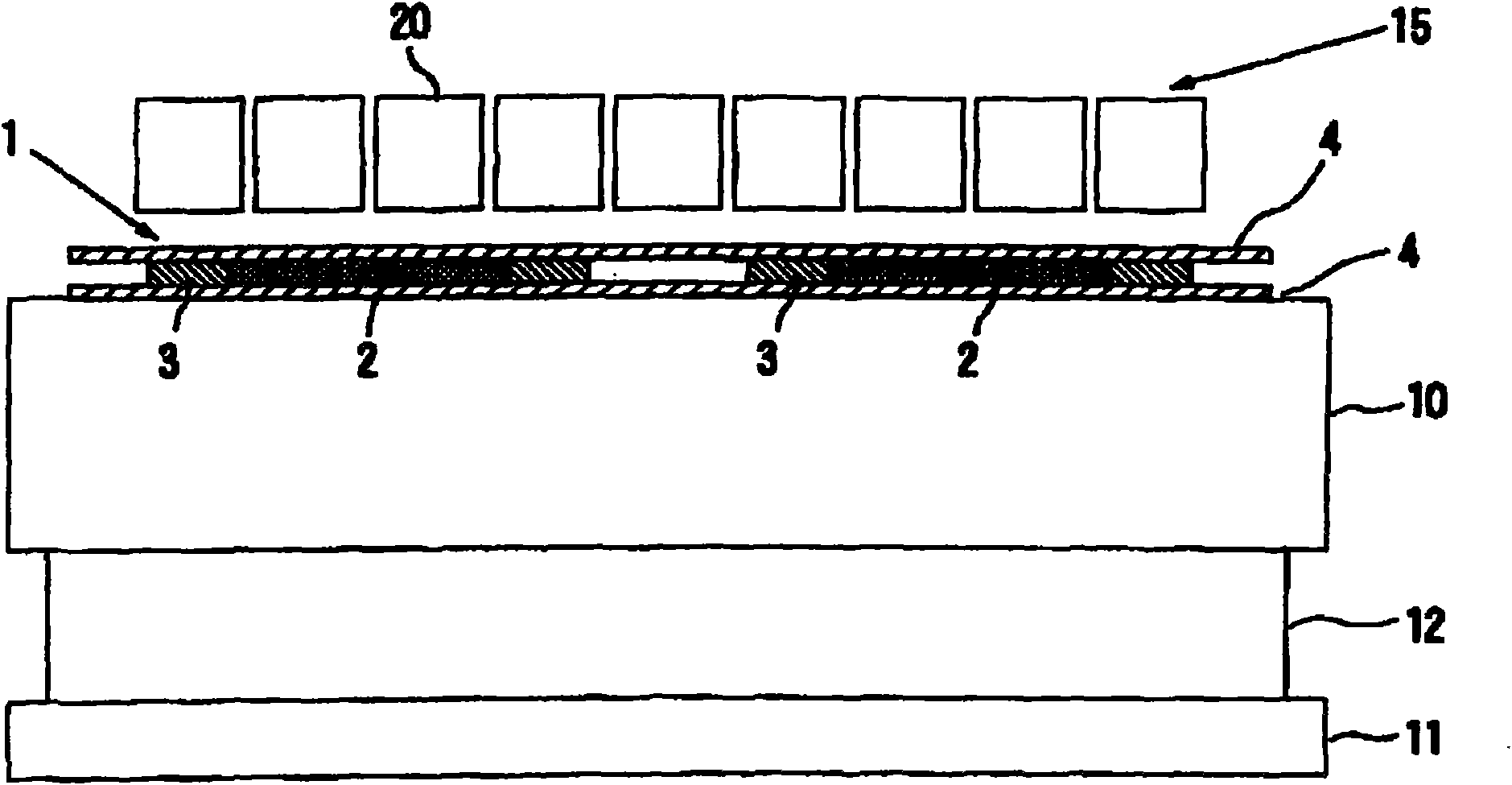

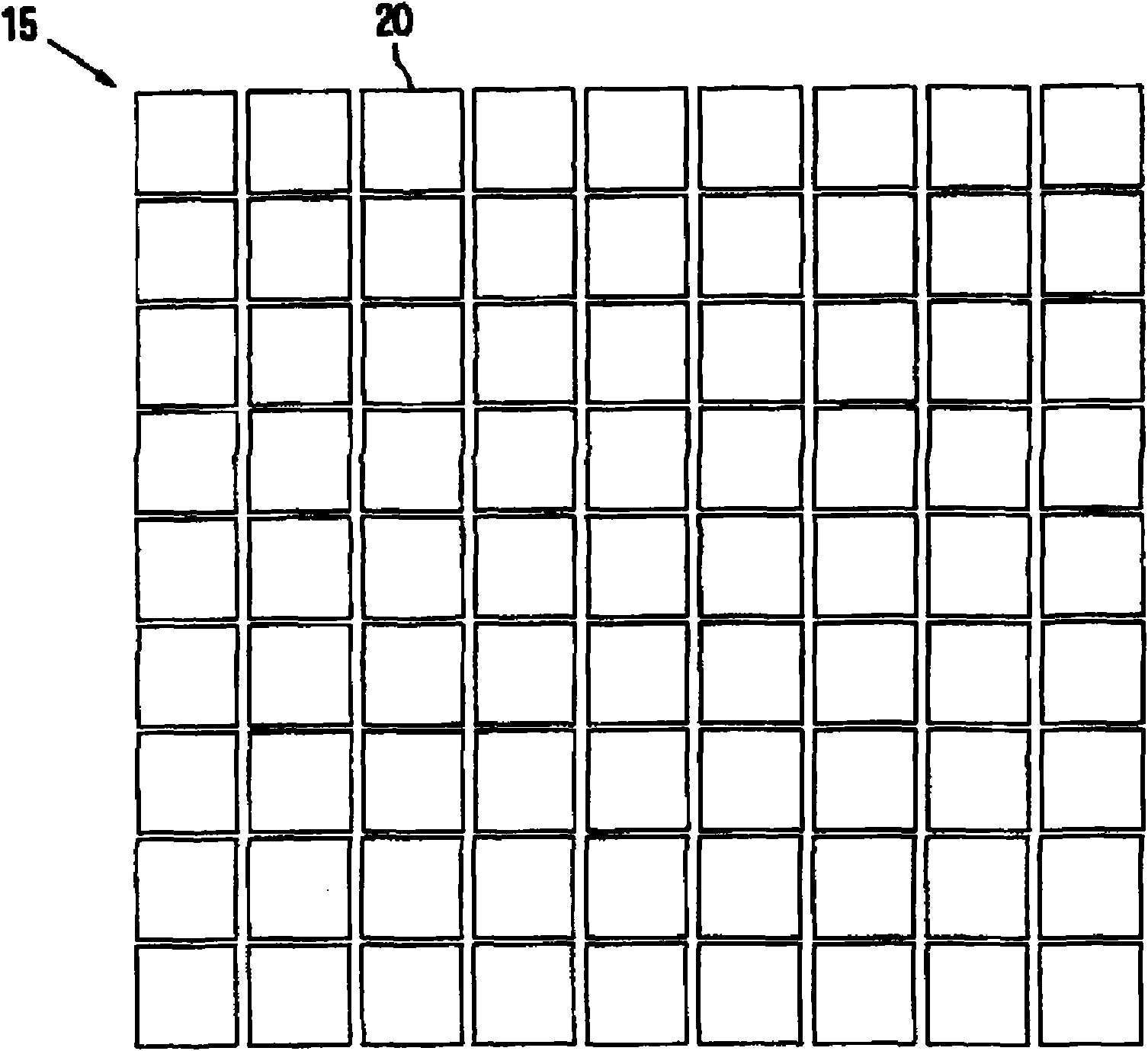

[0092] according to image 3 and Figure 4 With the structure shown, a light irradiation device was manufactured in which 130 light source segments were arranged vertically and horizontally. The specifications of the light source segment are as follows.

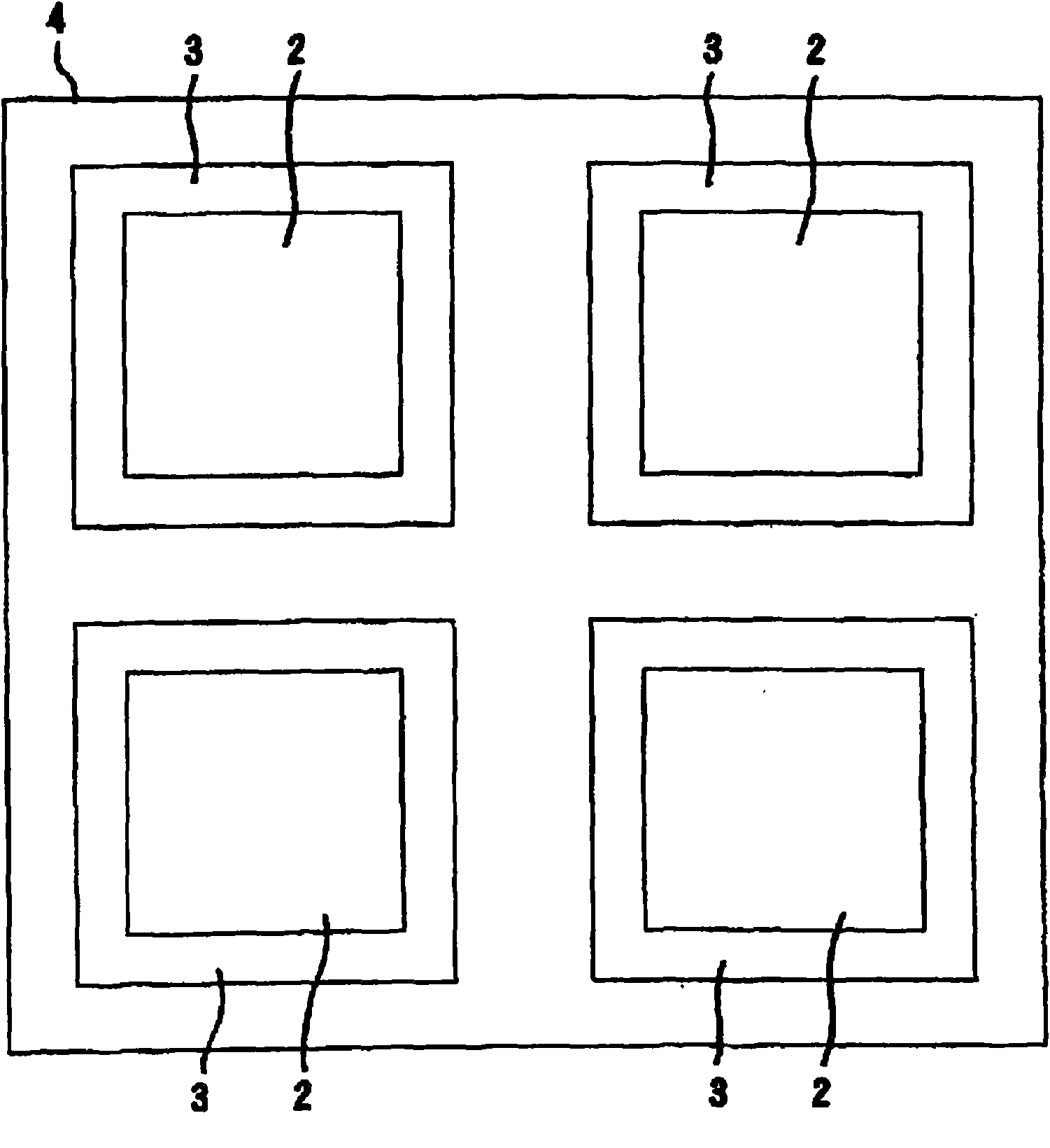

[0093] The vertical and horizontal dimensions of the substrate 21 are 50 mm×50 mm, and the overall length of the light guide member 26 is 45 mm.

[0094] The peak wavelength of the spectrum of the LED elements 25 is 385 nm, the full width at half maximum is ±5 nm, and nine light source segments are provided in one light source segment.

[0095] The optical filter 30 is a long-range optical filter having a dielectric multilayer film, and its cutoff wavelength is 380 nm.

[0096] The spectrum diagram of the light source section in the light irradiation device is shown in Figure 11 (a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com