Automatic cutting system and cutting method thereof

An automatic, cutting machine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

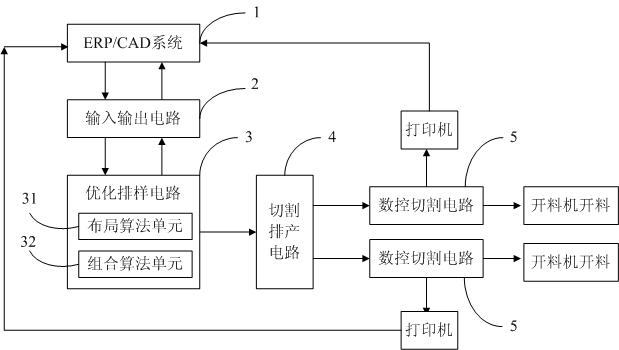

[0051] see Figure 1 to Figure 2 , an automatic material cutting system, including receiving the nesting task data of the ERP / CAD system 1, and returning the nesting result of the optimized nesting circuit 3 to the input and output circuit 2 of the ERP / CAD system;

[0052] Perform layout optimization calculation on the data of the input and output circuit 2, and generate an optimized layout circuit 3 of the optimal layout plan;

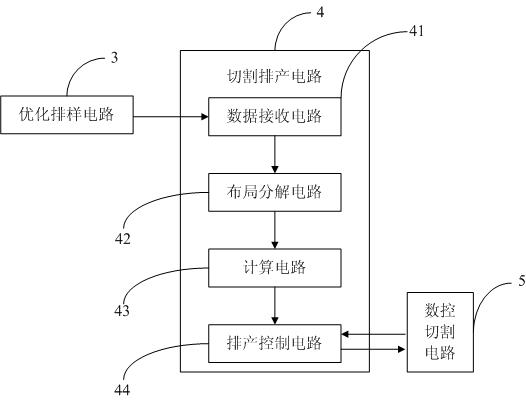

[0053] Receive the optimal layout diagram scheme of the optimized layout circuit 3, and reasonably decompose the scheme into a cutting and scheduling circuit 4 for the cutting tasks of multiple cutting machines;

[0054] The CNC cutting circuit 5 that receives the material cutting task of the cutting and scheduling circuit 4 and controls the material cutting machine to perform material cutting;

[0055] The input end of the input-output circuit 2 is connected to the ERP / CAD system 1, and the output end of the input-output circuit 2 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com