Heavy-calibre oil collection tube radiator for transformer

An oil collecting pipe and radiator technology, which is applied in the field of transformer accessories, can solve the problems of insufficient heat transfer oil, no energy saving, and increased power of the oil pump motor, so as to improve heat dissipation, avoid oil shortage, and reduce pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

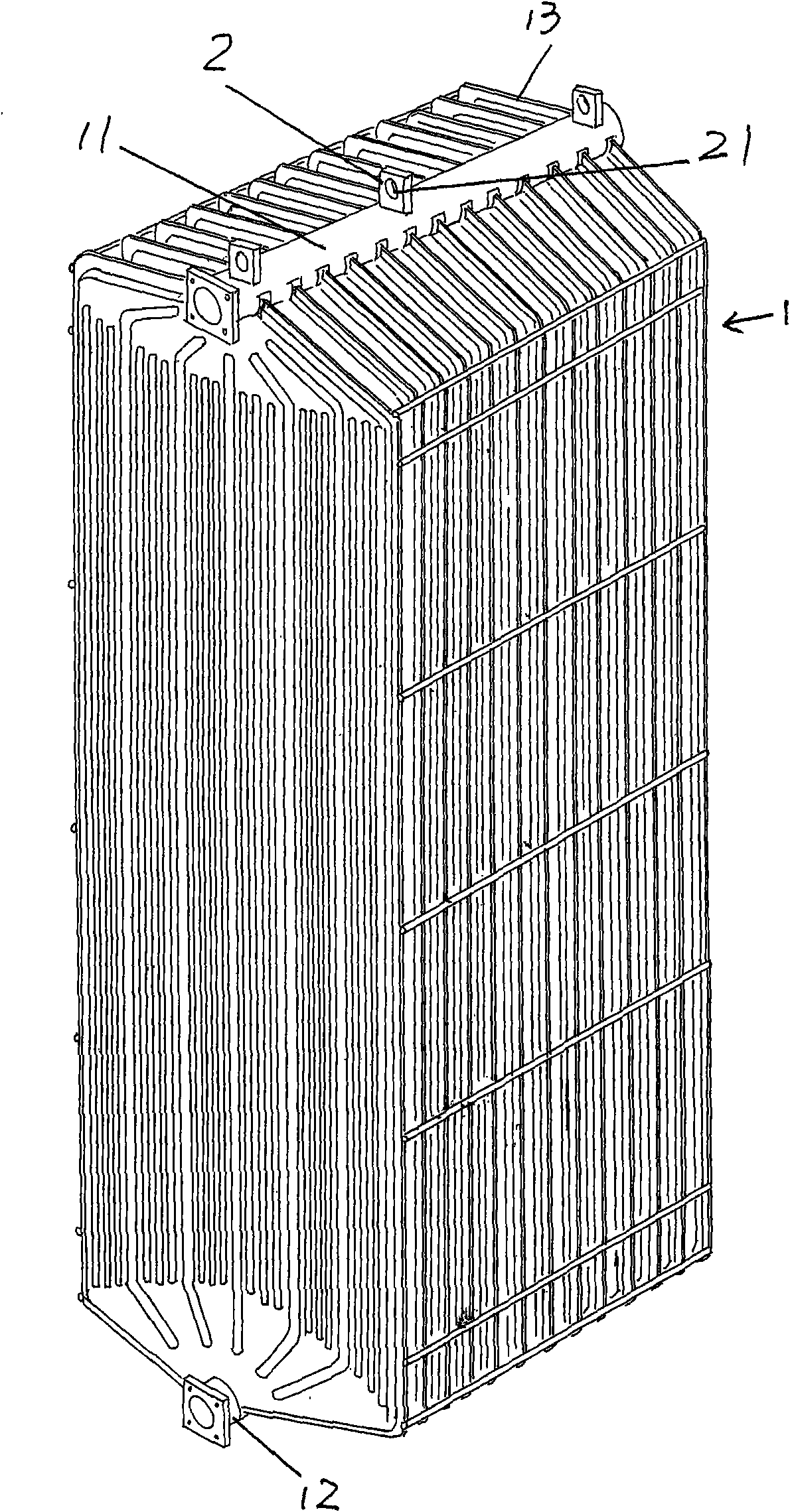

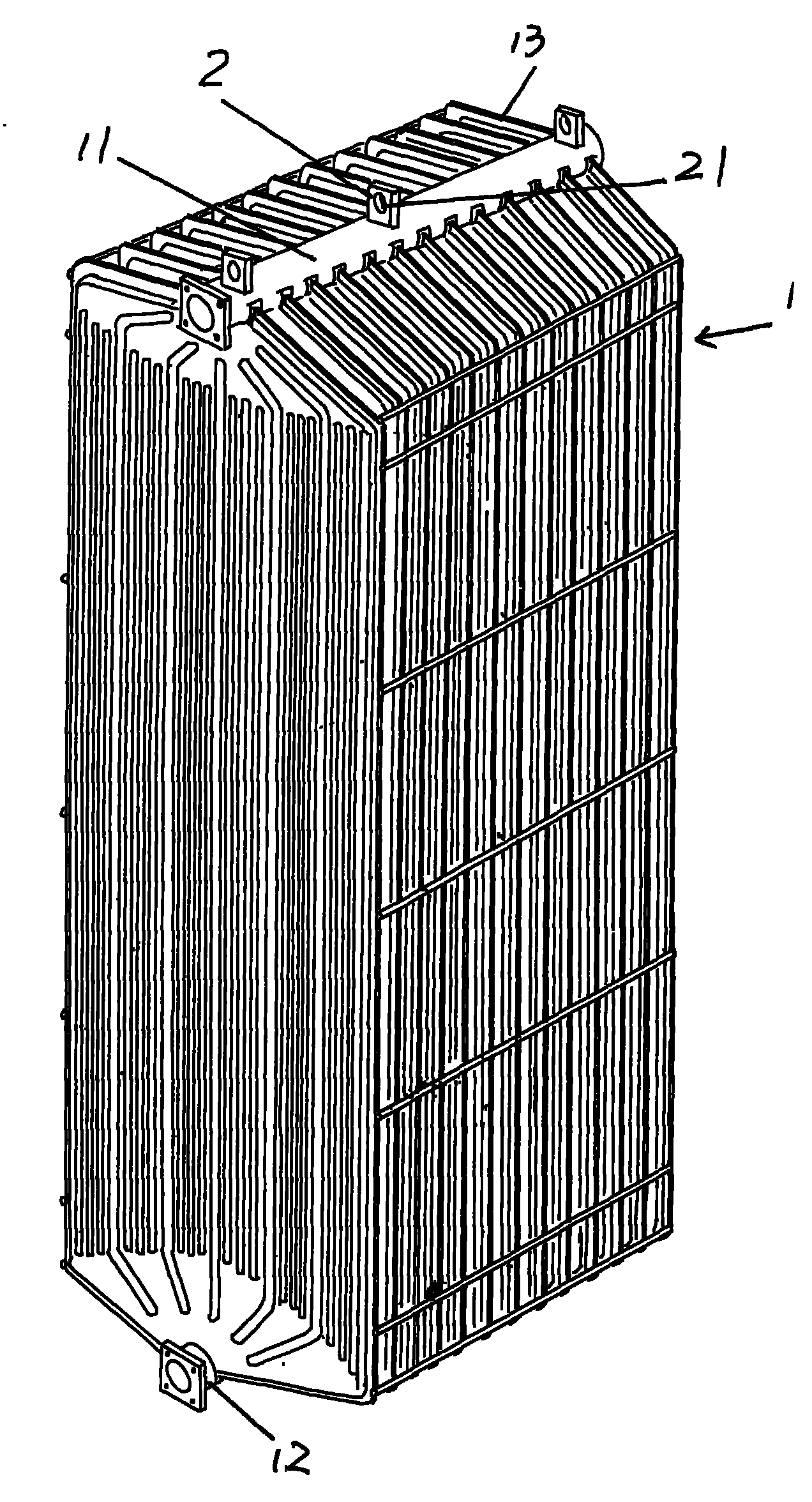

[0020] please see figure 1 , provides the radiator body 1, the radiator body 1 is made up of oil collecting pipe 11, oil return pipe 12 and a group of cooling fins 13, a group of cooling fins 13 are parallel to each other and keep the same distance between each other, each cooling fin 13 The upper end of each cooling fin 13 is connected with the oil collecting pipe 11 and the heat conducting oil cavity of each cooling fin 13 is communicated with the lumen of the oil collecting pipe 11; 12 lumens communicate. Lifting lugs 2 are fixed at intervals in the longitudinal direction of the aforementioned oil collecting pipe 11 and oil return pipe 12 , and hanging holes 21 are opened on the lifting lugs 2 . The preferred solution is: the lifting lugs 2 are arranged at intervals only in the length direction of the oil collecting pipe 11 , or the lifting lugs 2 are only arranged in the length direction of the oil return pipe 12 . It is self-evident that the effect of the lifting lug 2 ...

Embodiment 2

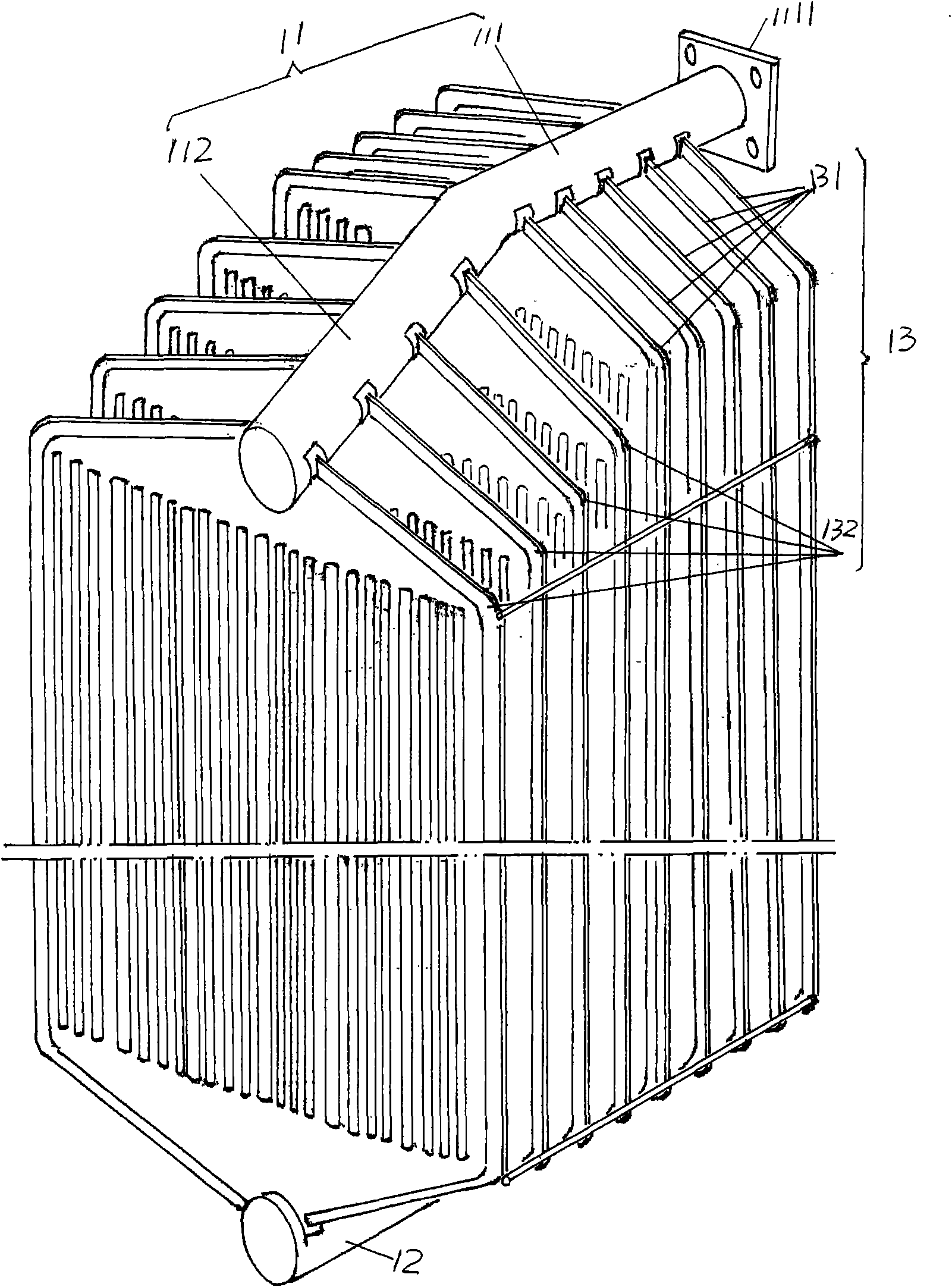

[0023] please see figure 2 , the given oil collecting pipe 11 is composed of a horizontal pipe section 111 and an inclined pipe section 112. Taking the current illustrated position as an example, the right end is a horizontal pipe section 111, while the left end is an inclined pipe section 112. The inclined pipe section 112 bends at one end of the horizontal pipe section 111. There is an oil inlet 1111 at the left end port of the horizontal pipe section 111. The hot oil from the transformer introduced by the oil inlet 1111 first enters the lumen of the horizontal pipe section 111 and then flows to the inclined pipe section 112. Since the oil collecting pipe 11 is formed by the horizontal pipe section 111 and the inclined pipe section 112, a group of cooling fins 13 are naturally formed of parallel cooling fins 131 and stepped cooling fins 132. One end of the oil return pipe 12 is connected and communicated, and the middle part of the upper and lower ends of the stepped coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com