Low-voltage self-healing type parallel capacitor combination top cover terminal

A capacitor and self-healing technology, which is applied to capacitors, circuits, electrical components, etc., can solve the problems of inconvenient use of the cover, poor electrode connection, etc., and achieve the effect of simplifying the structure and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

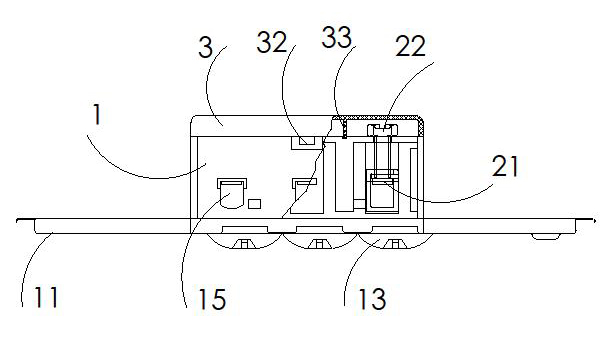

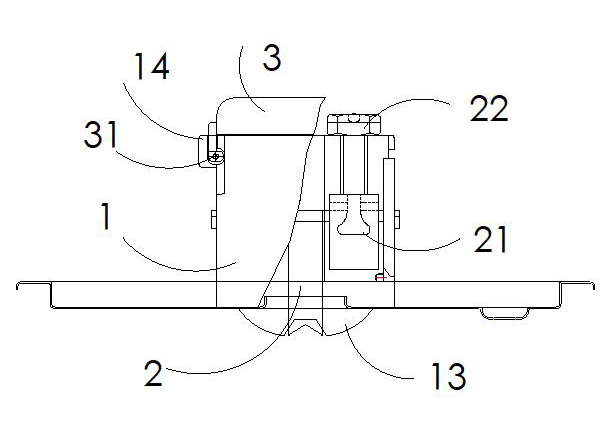

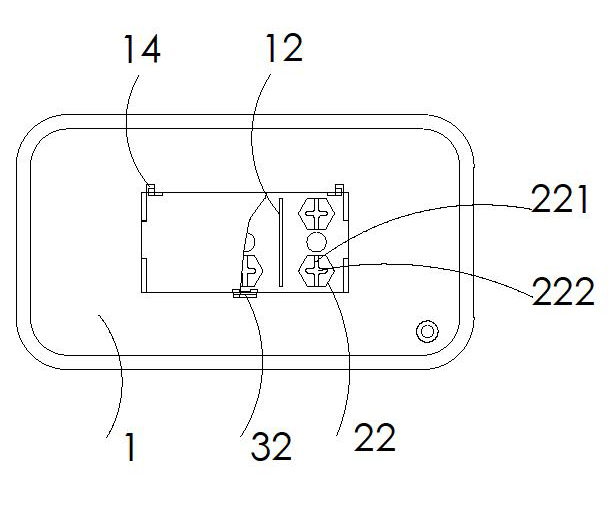

[0024] Embodiment 1: as figure 1 , figure 2 As shown, a low-voltage self-healing parallel capacitor combination cover terminal includes a base 1, a conductive copper plate 2 and a cover 3, the base 1 is provided with a base frame 11 made of iron plate, the base frame 11 and The conductive copper plate 2 and the base 1 are plastically integrated, and there is a distance between the base frame 11 and the conductive copper plate 2, and the middle part of the base 1 is provided with two arc-proof partitions 12 that isolate the three conductive copper plates 2 One end of the cover 3 and one side of the base 1 are pivotally connected by a pivot 31, and the inner side of the cover 3 is provided with a reinforcing rib 33 that also has the function of an arc-proof partition; one end of the conductive copper plate 2 is provided with a screw that can be used for lifting To tighten the clamping hoop 21 of the lead. The base frame 11 is integrated with the conductive copper plate 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com