Plate overhaul facility and overhaul method thereof

A technology for plates and equipment, applied in the field of plate repair equipment and its repair, can solve the problems of reduced product yield, inability to remove copper slag, poor cleaning effect, etc., and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

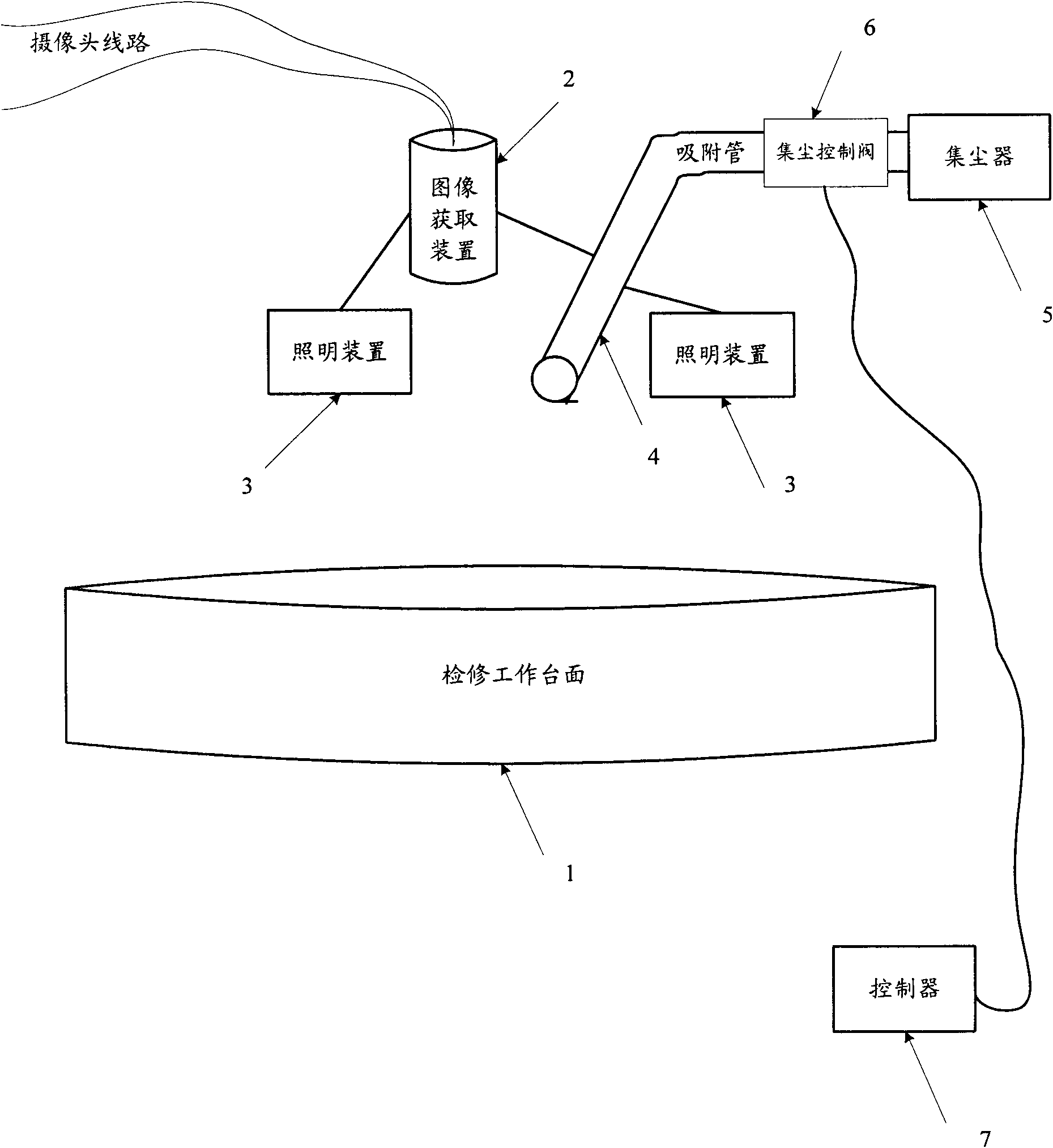

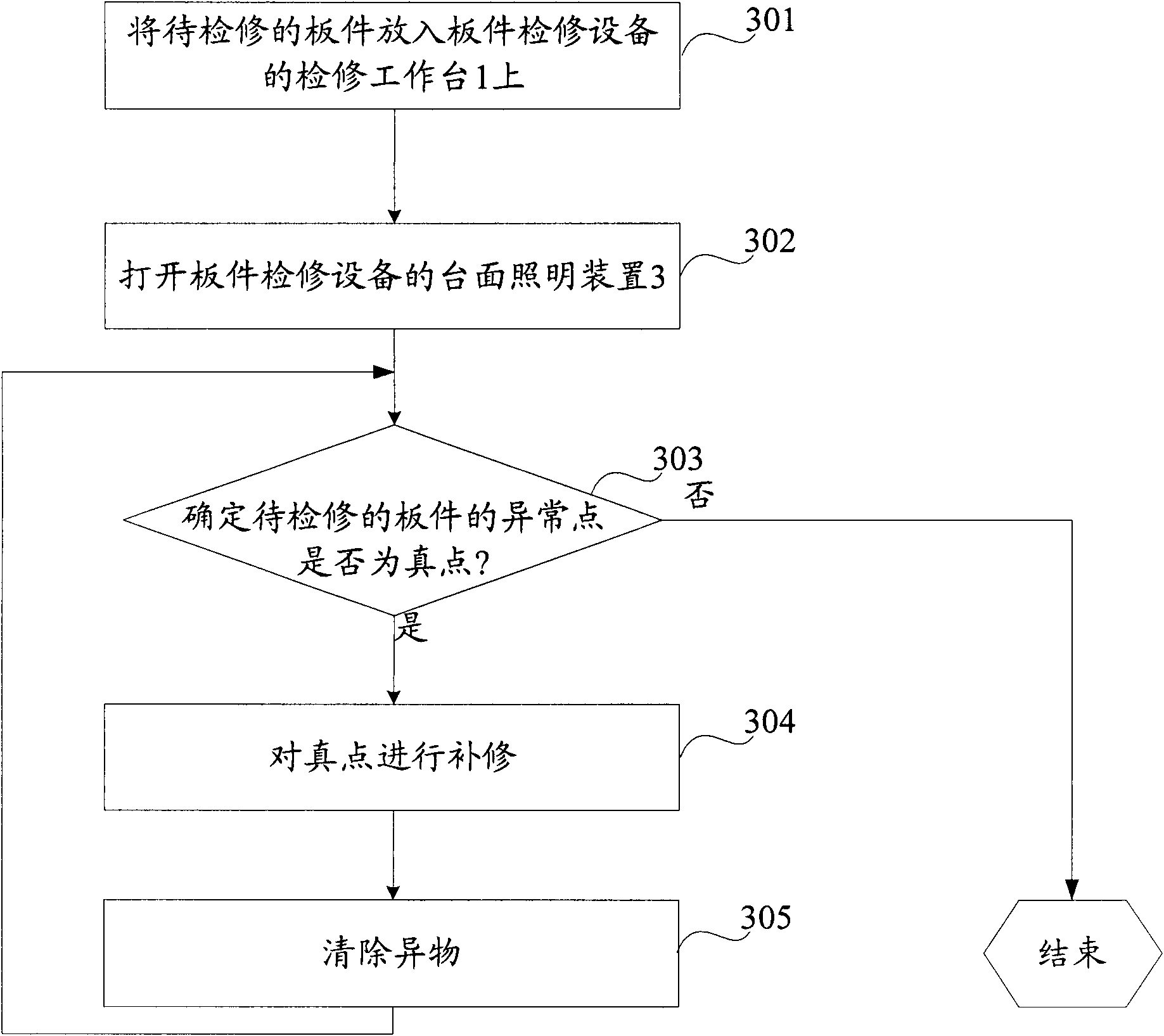

[0020] Since the existing panel maintenance equipment cannot effectively clean the foreign matter generated during the panel maintenance process, it is easy to cause new abnormalities, resulting in a decrease in the yield rate of the panel. Therefore, in the embodiment of the present invention, in the panel maintenance equipment The cleaning unit is added, which can effectively clean the foreign matter generated during the inspection and maintenance of the board, and greatly improve the yield rate of the board.

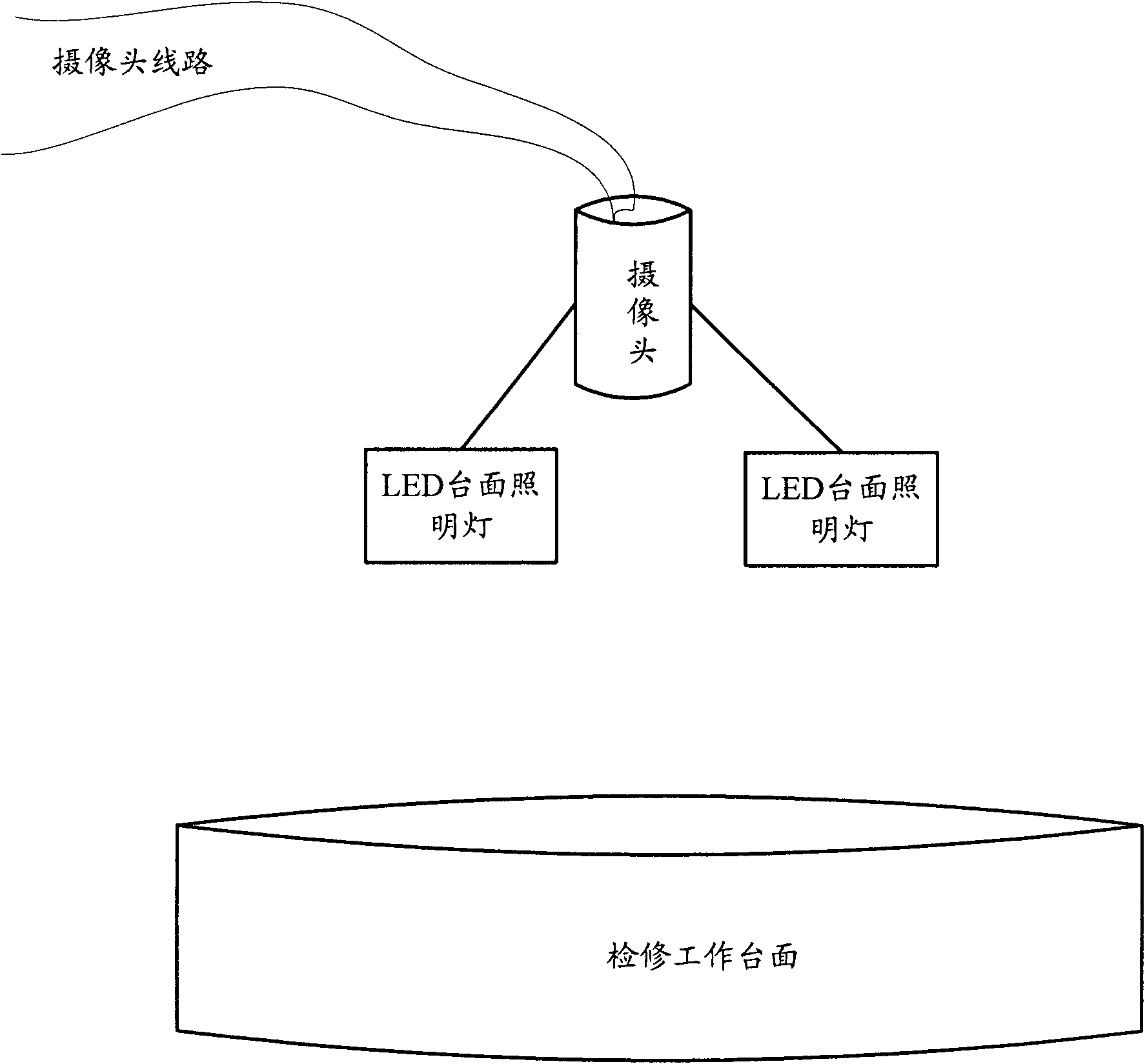

[0021] The panel inspection equipment in the embodiment of the present invention includes: an inspection table for carrying the board, an image acquisition device and at least one lighting device located above the inspection table, and the equipment also includes: an adsorption tube, Dust collector, dust collection control valve and controller; wherein,

[0022] The adsorption tube is located above the inspection table;

[0023] The dust collection control valve is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com