Artificial stone bathtub and method for manufacturing same

A technology of artificial stone and bathtub, which is applied in the direction of bathtub, shower, sanitary equipment, etc. It can solve the problems of high price of natural stone, easy slipping of ceramic bathtub, difficulty in mass production, etc., and achieves the advantages of industrialization promotion, good gloss and saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

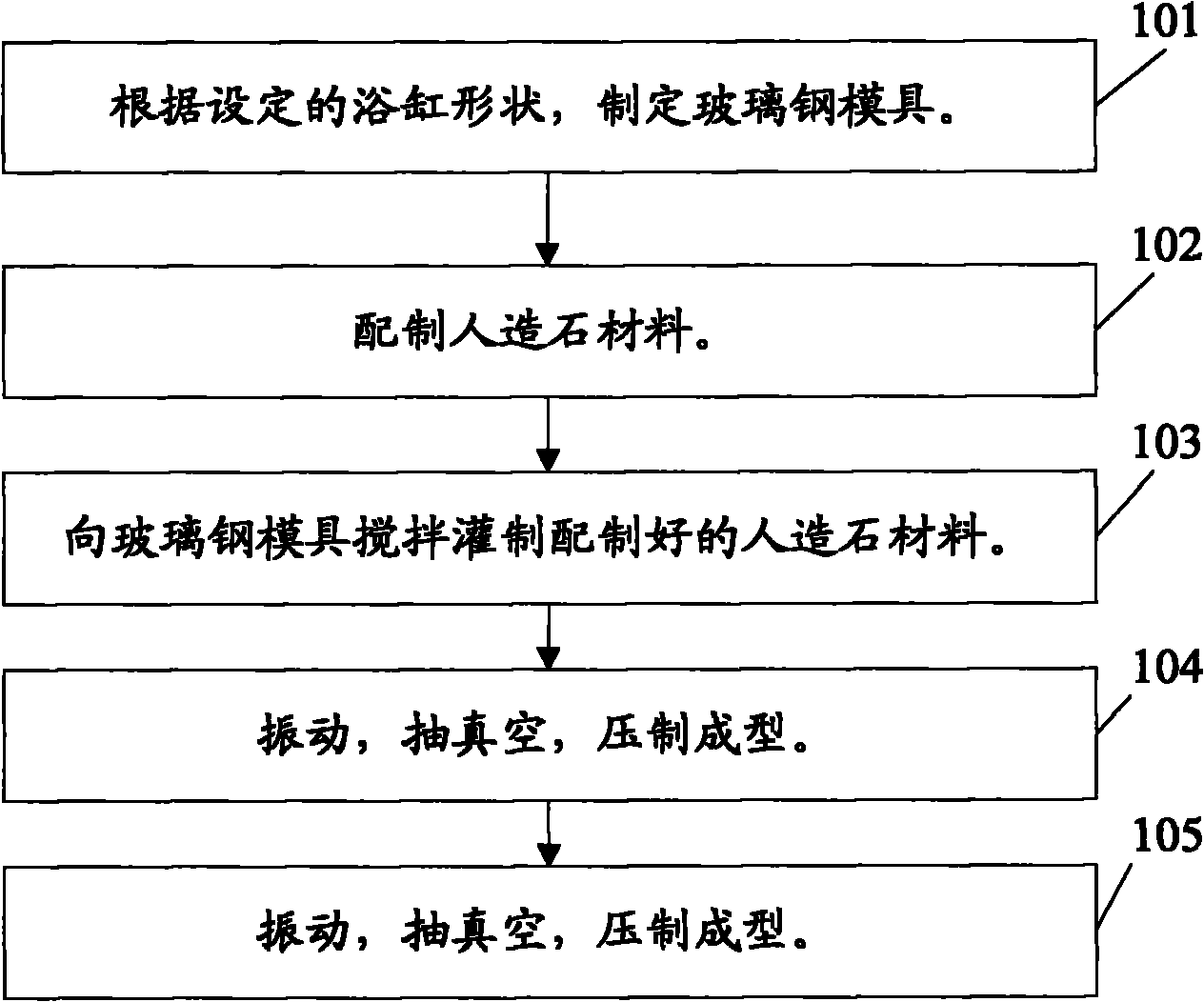

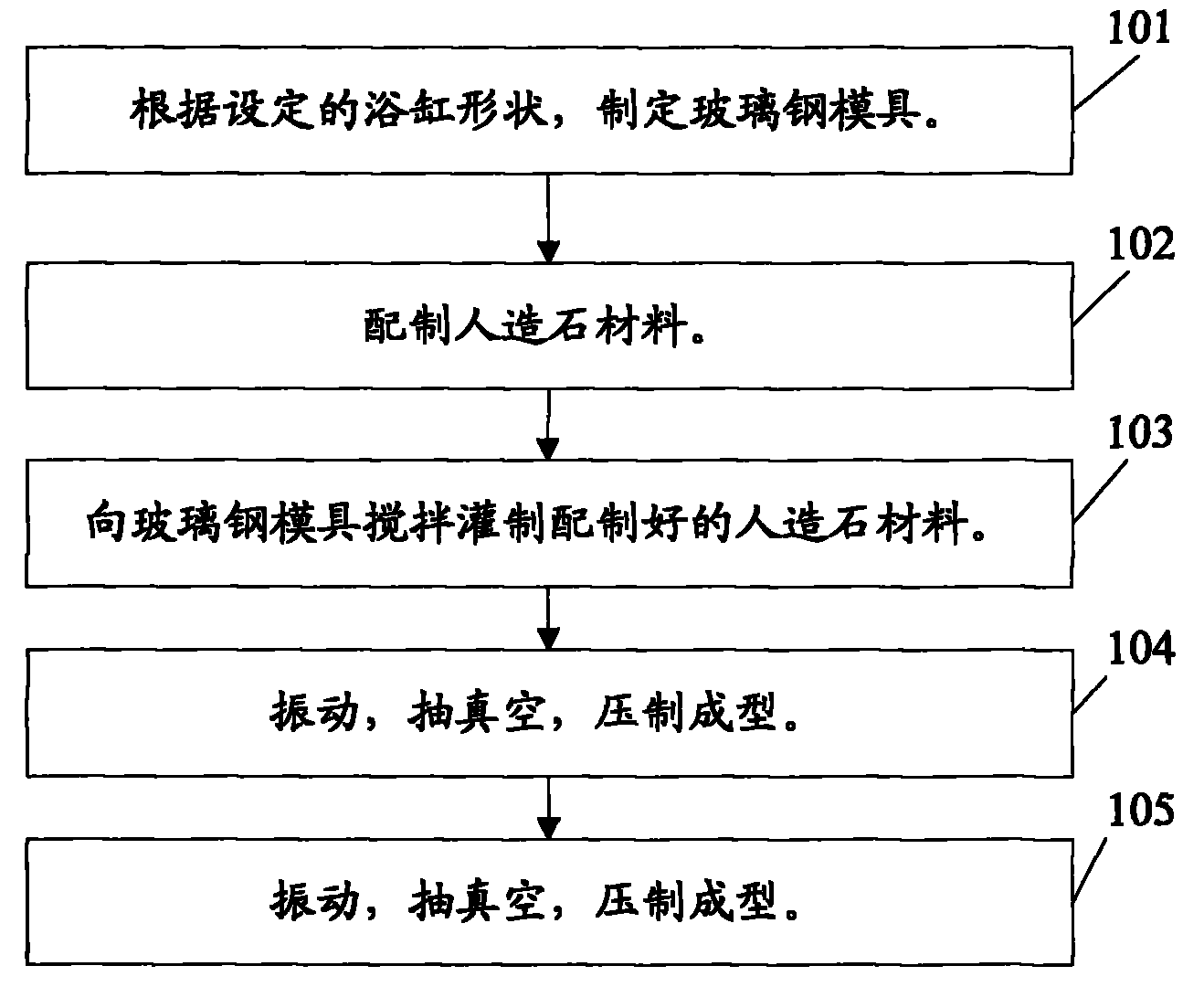

[0020] see figure 1 As shown, the production process of a kind of bathtub provided by the present embodiment comprises the following steps:

[0021] Step 101: Make a fiberglass mold according to the set shape of the bathtub.

[0022] According to the design requirements (including engraving requirements), the glass fiber reinforced plastic mold is manufactured according to the design requirements 1:1.

[0023] Step 102: Prepare artificial stone material.

[0024] According to the customer's performance requirements, mix multiple or one natural stone powder and resin glue according to the set ratio.

[0025] Step 103: Stir and pour the prepared artificial stone material into the FRP mold.

[0026] The prepared artificial stone material is stirred into a fiberglass mold, so that the poured natural stone and resin are glued into the fiberglass mold to form a bathtub.

[0027] In this embodiment, a high-strength glass fiber reinforced plastic mold is used, which can resist hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com