Vehicle surface deep scratch repairing process

A technology for car surface and scratches, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquids on surfaces, etc. It can solve problems such as difficult coating repair and difficult quality assurance, and achieves reasonable process structure and high quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings .

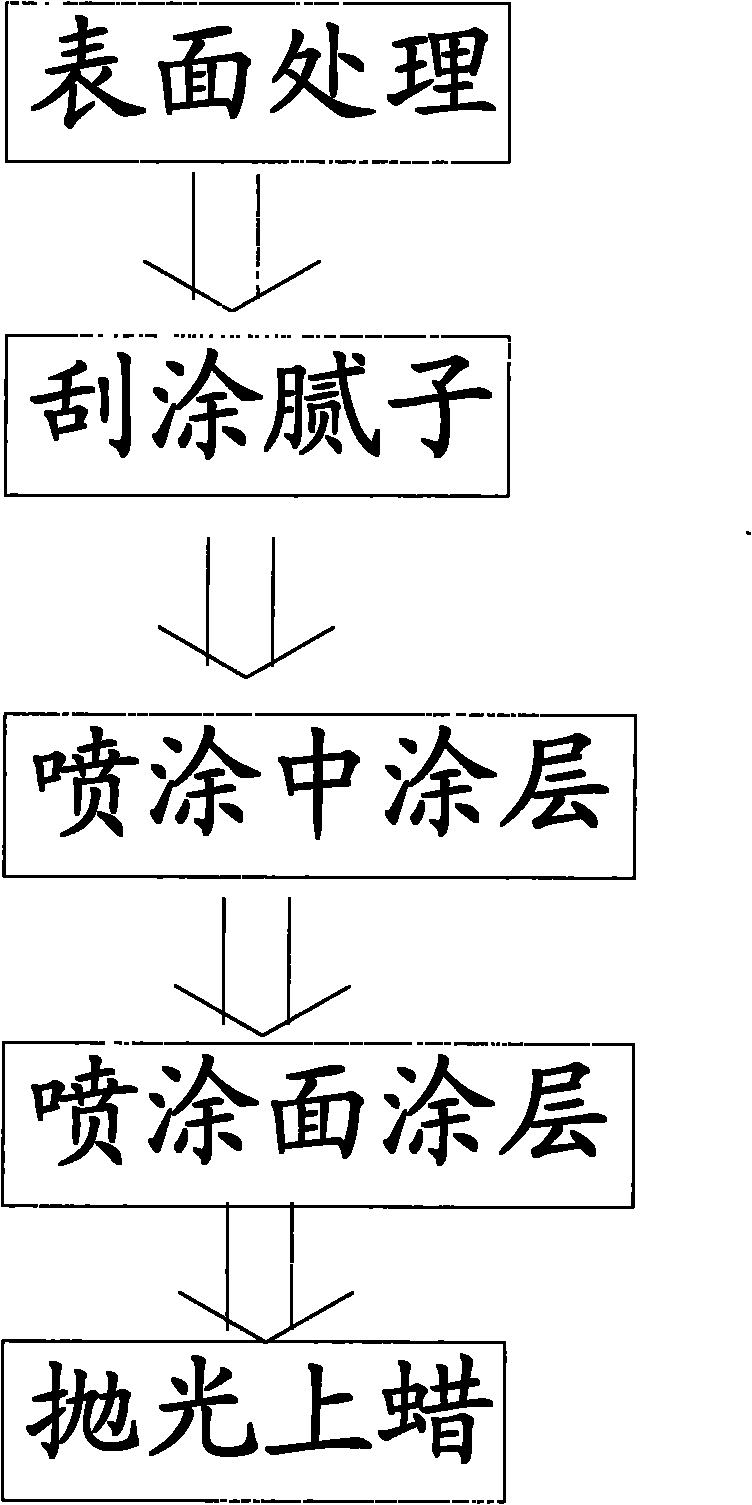

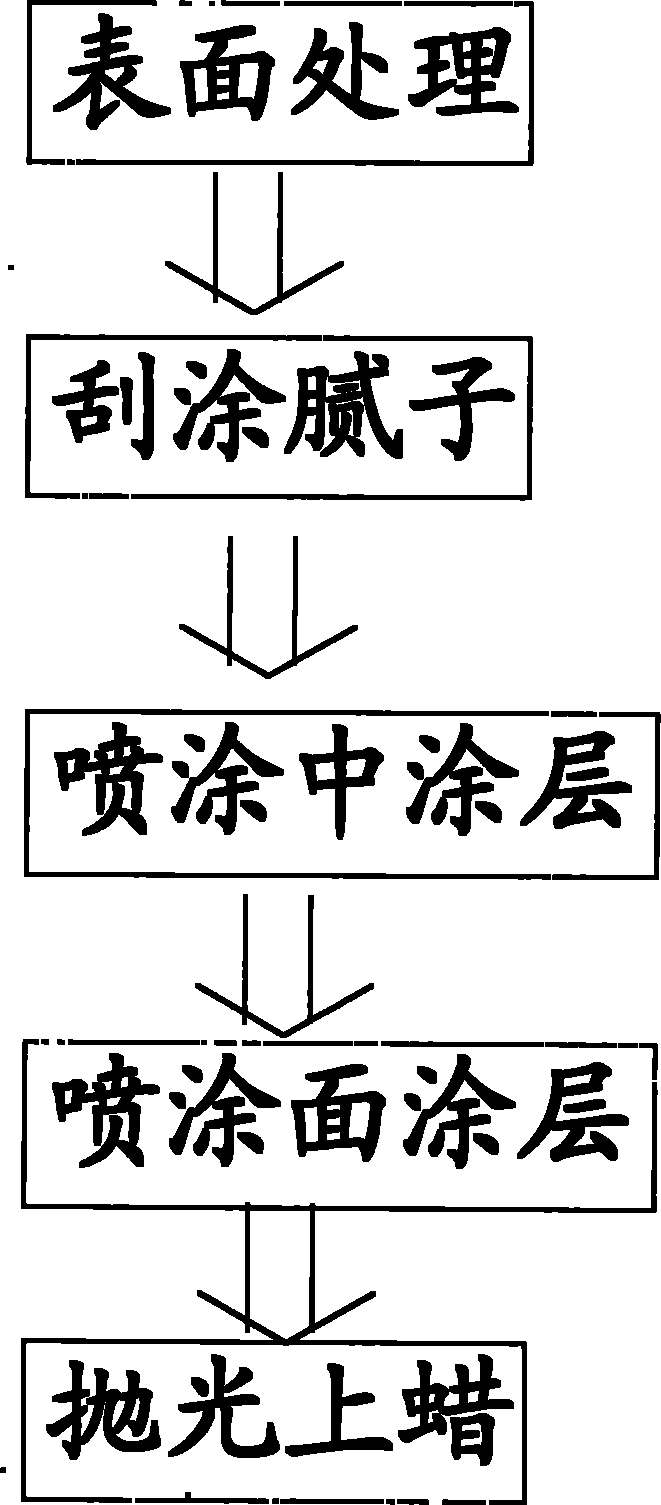

[0015] Such as figure 1 Shown is the process flow chart of the car surface depth scratch repair process of the embodiment of the present invention, the scratch repair process steps are as follows: first, surface treatment, processing, cleaning, drying surface coating, primer and antirust paint ; Secondly, scrape the putty, apply the quick-drying putty to the metal surface and level it and clean it; then, spray the middle coat, spray the primer twice and smooth it; then, spray the top coat, including spraying, warm grinding and Finishing process; finally, polishing and waxing.

[0016] The operation is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com