Assembly type tungsten carbide circular saw blade

A technology of cemented carbide teeth and circular saw blades, which is applied in the field of steel processing tools, can solve the problems of scrapped saw blades, unrepairable, high prices, etc., and achieve the effect of reducing the cost of use and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

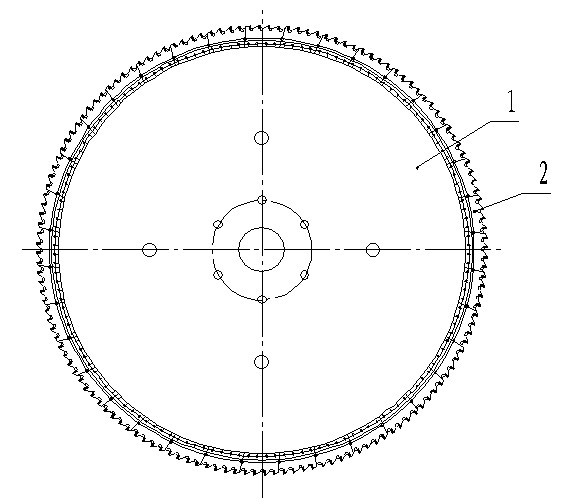

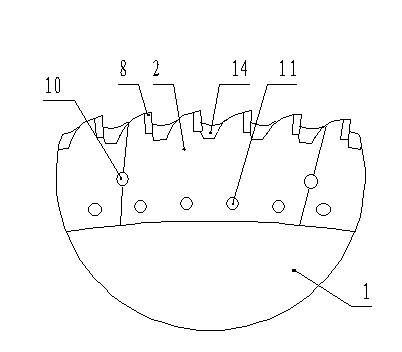

[0025] see figure 1 , figure 2 , a plurality of inlaid tooth holders 2 are closely arranged in a ring shape, the inner edge of which is inlaid and riveted to the periphery of the saw blade body 1, and the sawing blade 8 pressed on the outer edge is used for cutting the workpiece. The saw blade body 1 and the inlaid tooth holder 2 are riveted together by connecting rivets 11, and the function of the saddle rivet 10 is to stabilize the relative positions of the inlaid tooth holders 2 and keep them in the same plane.

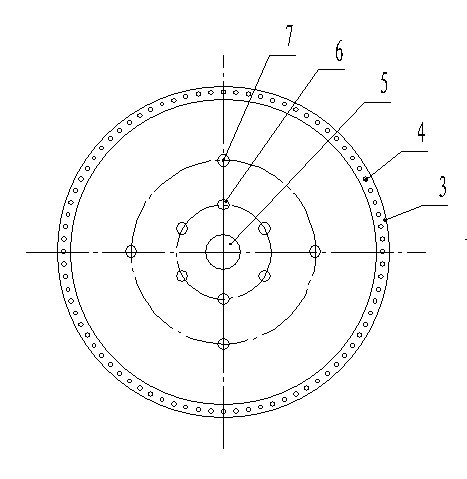

[0026] see image 3 , Figure 4 The saw blade body 1 is a thin disc body with holes, on which a central hole 5, a transmission hole 6 and a process hole 7 are arranged, and a shoulder 3 is arranged on the periphery, and rivet holes 4 are evenly distributed on the shoulder 3.

[0027] see Figure 5 , Figure 6 , the socket 13 on the mosaic tooth holder 2 is nested on the shoulder 3 of the saw blade body 1 , and the riveting hole 12 on it corresponds to the riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com