Method of detection of welding workpiece position using movable electrode

一种工件位置、检测方法的技术,应用在焊接设备、电阻焊设备、制造工具等方向,能够解决易成为不稳定、焊接工件变形、难可动电极与焊接工件接触时刻等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

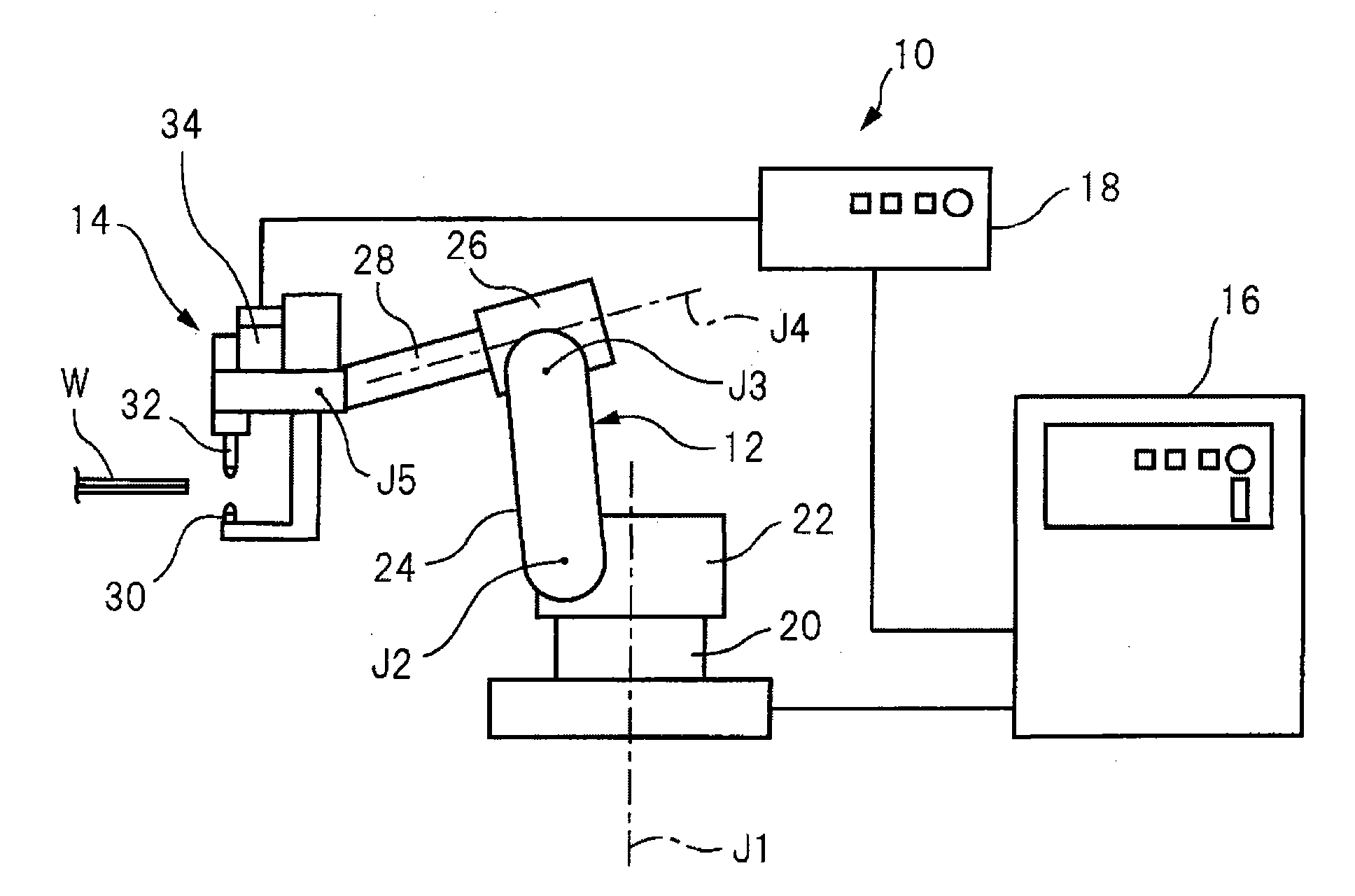

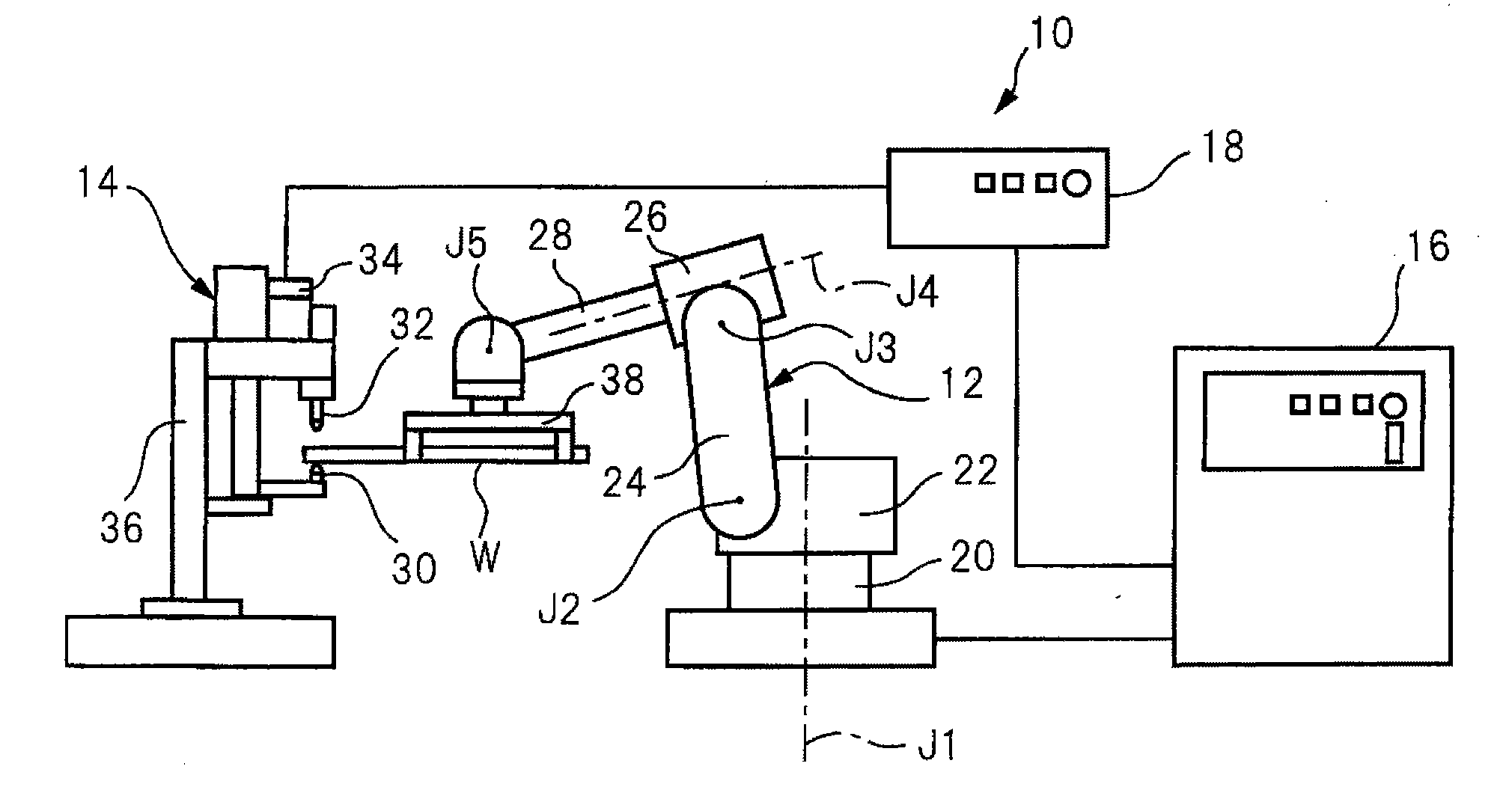

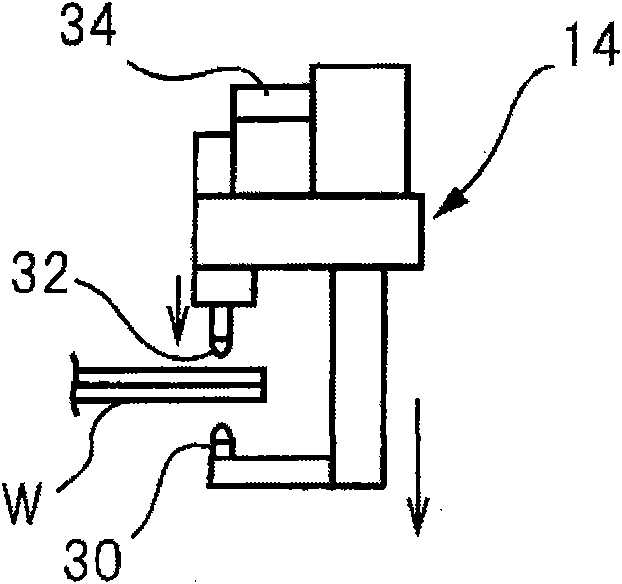

[0121] refer to Figure 6 The A1st embodiment of the welding workpiece position detection method of the present invention will be described. In the A1 embodiment, in figure 1 In the spot welding system 10 shown, the speed Vg at which the servo motor 34 drives the movable electrode 30 is set to 0, and the spot welding gun 14 is held by the articulated robot 12 in a state where the movable electrode 30 is stationary relative to the counter electrode 32 , making it relatively move at a speed Vr relative to the welding workpiece W fixed on the workpiece fixing table (not shown). In addition, a torque limit is set for the servo motor 34 for driving the movable electrode 30, and the torque does not increase above a constant value. In order to suppress the deformation of the welding workpiece W caused by the pressing of the movable electrode 30, it is desirable to set the torque limit to a value as low as possible.

[0122] In the present embodiment, at first, the workpiece W to b...

Embodiment A2

[0137] The A2 embodiment differs from the A1 embodiment in that figure 1 In the shown spot welding system 10, the speed Vg at which the movable electrode 30 is driven by the servo motor 34 is not 0, and while the movable electrode 30 is moved by the servo motor 34, the spot welding gun 14 is held by the articulated robot 12, so that The movable electrode 30 moves relative to the welding workpiece W fixed on the workpiece fixing table (not shown) at the speed Vr, and the rest is the same as that of the A1st embodiment. Therefore, here, different parts will be mainly described, and the description of the same parts will be omitted.

[0138] In the A1 embodiment, there is an advantage that, since the speed Vg at which the servo motor 34 drives the movable electrode 30 is set to 0, and the movable electrode 30 is kept stationary relative to the counter electrode 32, there is almost no occurrence of a fault caused by the movable electrode 30. Fluctuation of the current or torque o...

Embodiment A3

[0158] refer to Figure 11 A third embodiment of the welding workpiece position detection method of the present invention will be described. In the A3 embodiment, in figure 1 In the spot welding system 10 shown, the speed Vg at which the servo motor 34 drives the movable electrode is set to 0, and the spot welding gun 14 is held by the articulated robot 12 in a state where the movable electrode 30 is stationary relative to the counter electrode 32, The spot welding gun 14 is relatively moved at a speed Vr with respect to a welding workpiece W fixed on a workpiece fixing table (not shown). In addition, a torque limit is set for the servo motor 34 for driving the movable electrode 30, and the torque does not increase when it exceeds a constant value or more. In order to suppress the deformation of the welding workpiece W caused by the pressing of the movable electrode 30, it is desirable to set the torque limit to a value as low as possible.

[0159] In the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com