Array induction logging coil system for measuring formation resistivity

A technology of formation resistivity and array induction, which is applied in the fields of electrical/magnetic detection for logging records, wellbore/well components, earthwork drilling and production, etc. It can solve problems that are difficult to obtain, complicated in circuit design, difficult in processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

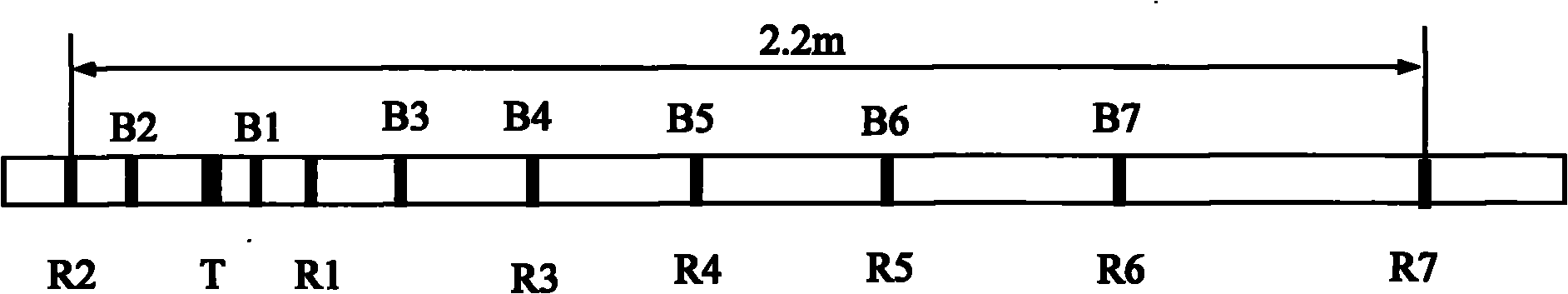

[0060] figure 1 It is a schematic diagram of the first arrangement of the coil system in the present invention.

[0061] The multi-array multi-frequency induction coil system structure is composed of 1 transmitting coil and 7 independent 2-coil sub-arrays. In the figure, T represents the transmitting coil; R1, R2, R3, R4, R5, R6 and R7 represent 7 main receiving coils. Coils; B1, B2, B3, B4, B5, B6 and B7 represent 7 shielded coils. The second short sub-array is placed on one side alone, and the remaining 6 sub-arrays are on the other side. The shielding coils of sub-arrays R4, R5, R6 and R7 coincide with the main receiving coils of sub-arrays R3, R4, R5 and R6. This method can reduce the influence of the coil bobbin on other sub-arrays due to the cancellation of the direct-coupled signal during assembly.

Embodiment 2

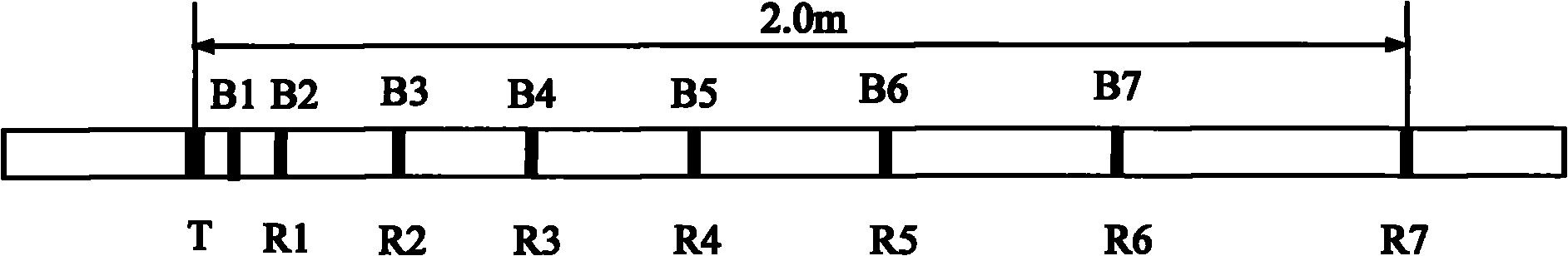

[0063] figure 2 It is a schematic diagram of the second arrangement of the coil system in the present invention. All subarrays are arranged on one side, and the shielding coils of subarrays R1, R2, R3, R4, R5, R6, and R7 coincide with the main receiving coils of subarrays R1, R2, R3, R4, R5, and R6. This method shortens the length by 0.2m compared to the first method.

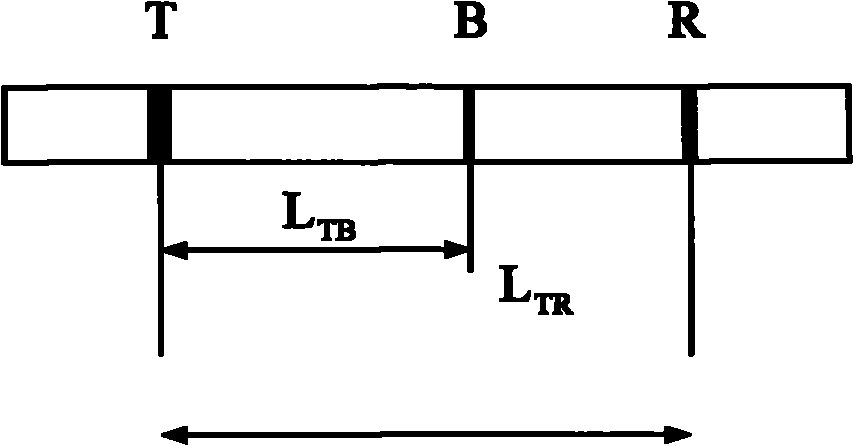

[0064] image 3 for correspondence figure 1 and figure 2 Schematic diagram of the 3-coil system subarray structure. image 3 is corresponding figure 1 and figure 2 Schematic of the 3-coil system subarray. The shielding coil B is arranged between the transmitting coil and the main receiving coil to cancel the direct coupling signal between the transmitting and the main receiving, and its number of turns and spacing are designed to meet the requirements of the present invention.

[0065] Fig. 4 is a diagram of radial differential and integral geometric factors corresponding to the multi-array coil syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com