Site large-scale direct shearing test device of shearing strength of concrete and basement adhesion surface

A technology of shear strength and test equipment, which is applied in the direction of testing material strength by applying stable shear force, can solve problems such as complicated operation, low test accuracy, and equipment installation error, and achieves wide application, high test accuracy, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

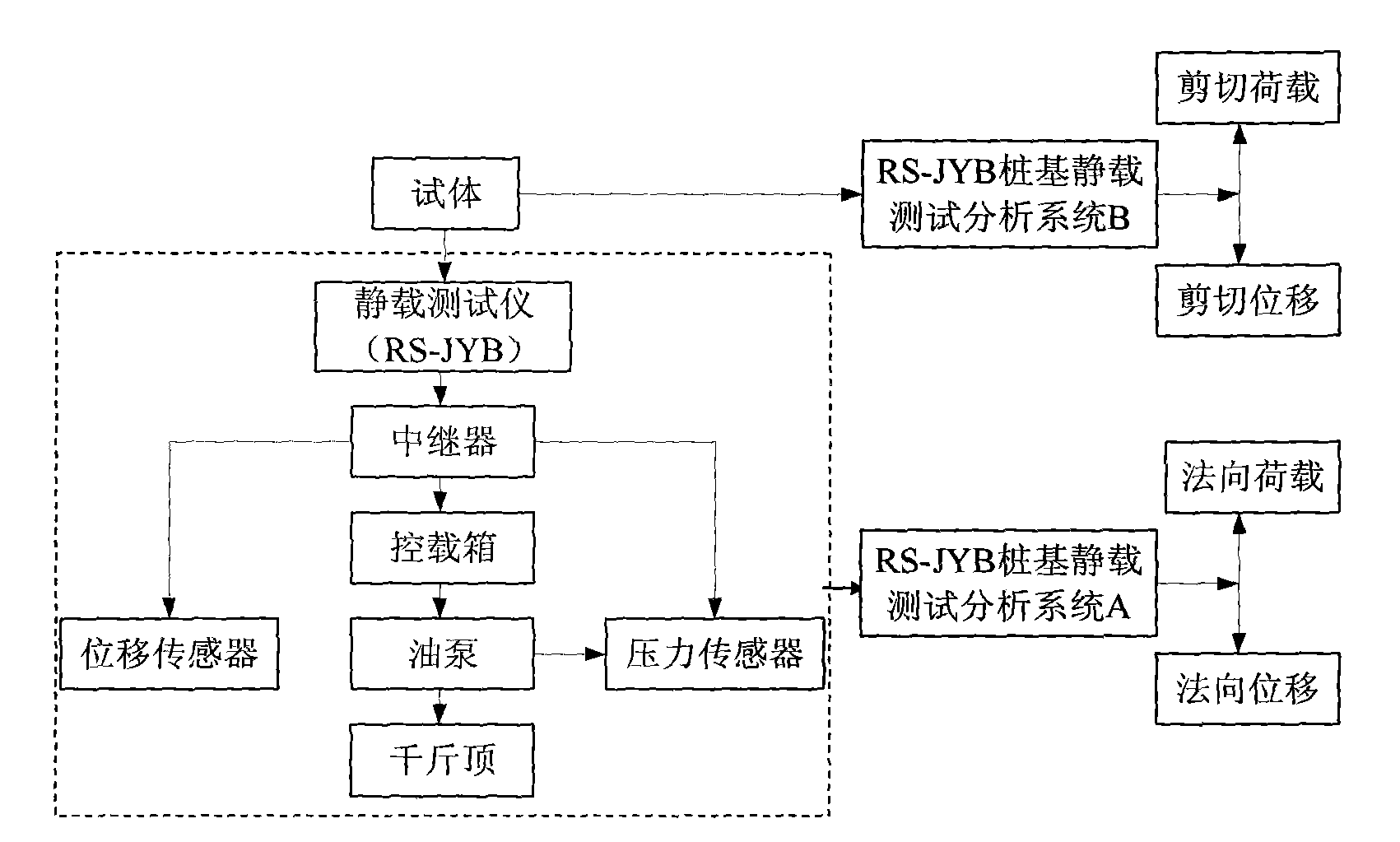

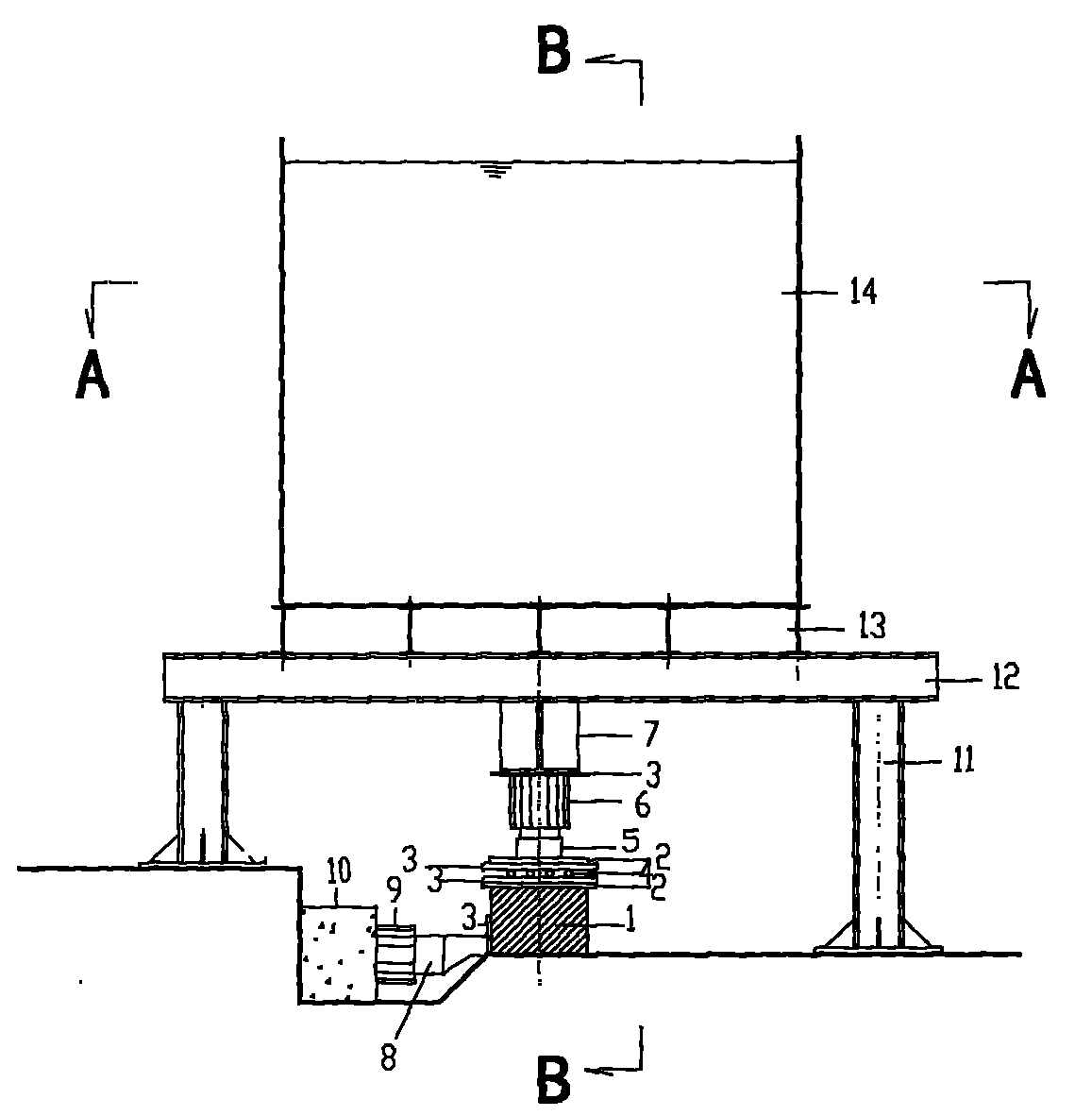

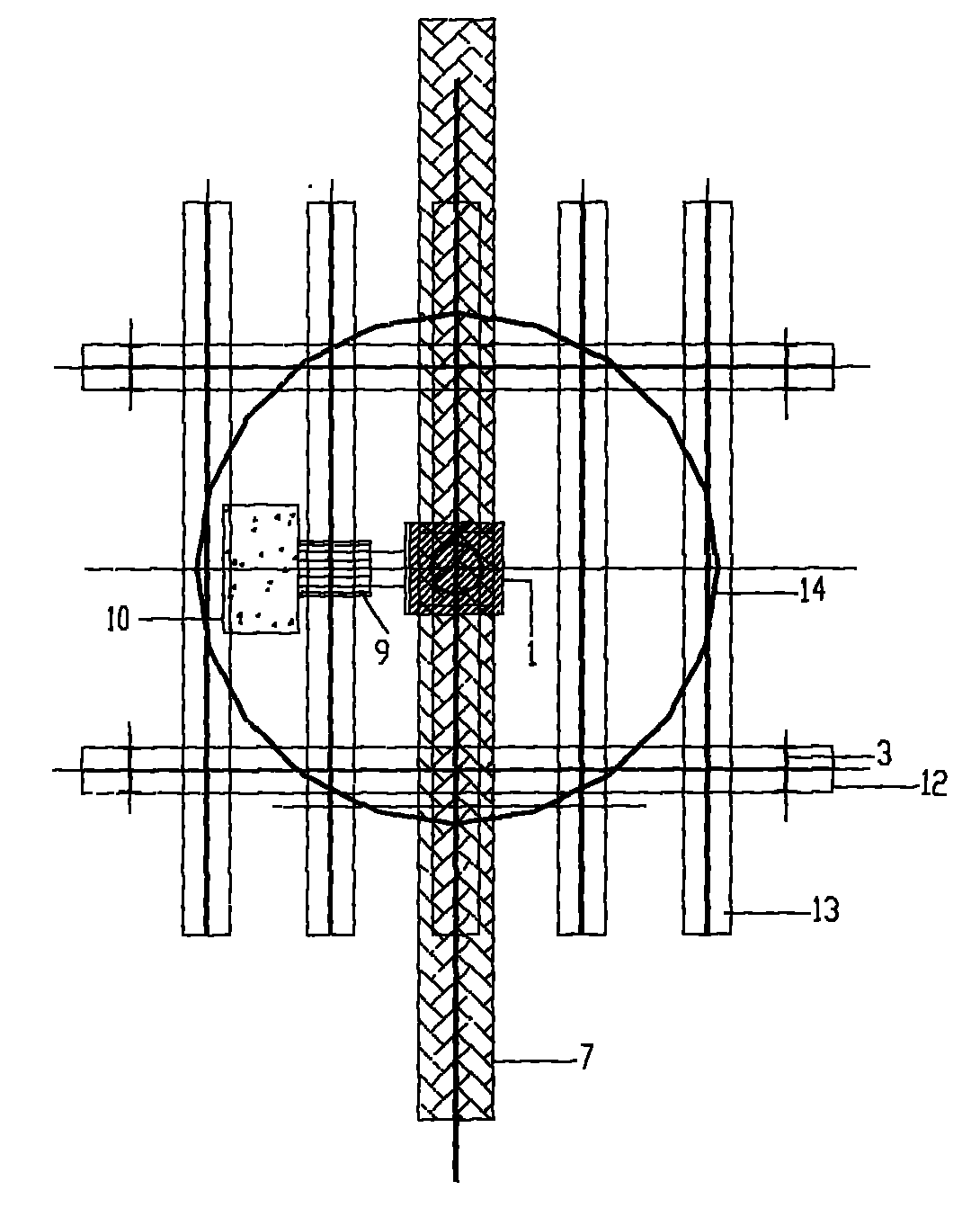

[0023] A direct shear test device for the shear strength of the cemented surface of concrete and bedrock, its structure is as follows figure 2 as shown, figure 2 The cross-sectional view of A-A in the middle is as follows image 3 as shown, figure 2 The cross-sectional view of B-B in the middle is as follows Figure 4 As shown: the device includes a circular backing plate 2, a square backing plate 3, a ball row 4, a transmission column 5, a vertical pile foundation static load test system 6, a reaction beam 7, a force transmission block 8, and a horizontal pile foundation static load test System 9, support column 11, beam 12, longitudinal beam 13, casing 14. Vertical pile foundation static load test system 6 controls vertical load application and vertical displacement data collection, and is connected to the top surface of test body 1 below reaction beam 7, and horizontal pile foundation static load test system 9 controls shear load application and shear load. The displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com