Thin type transformer for high-frequency induction heating

A high-frequency induction heating and transformer technology, which is applied in the direction of transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the problems such as difficulty in miniaturization of transformer 82 and difficulty in reducing the distance of induction heating coil 81, etc. Achieve the effect of shortening the distance and increasing the amount of supplied current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the thin transformer for high-frequency induction heating according to the present invention will be described in detail with reference to the drawings. In addition, the following description is to facilitate understanding of the description of the embodiment, and should not limit the understanding of the present invention thereby.

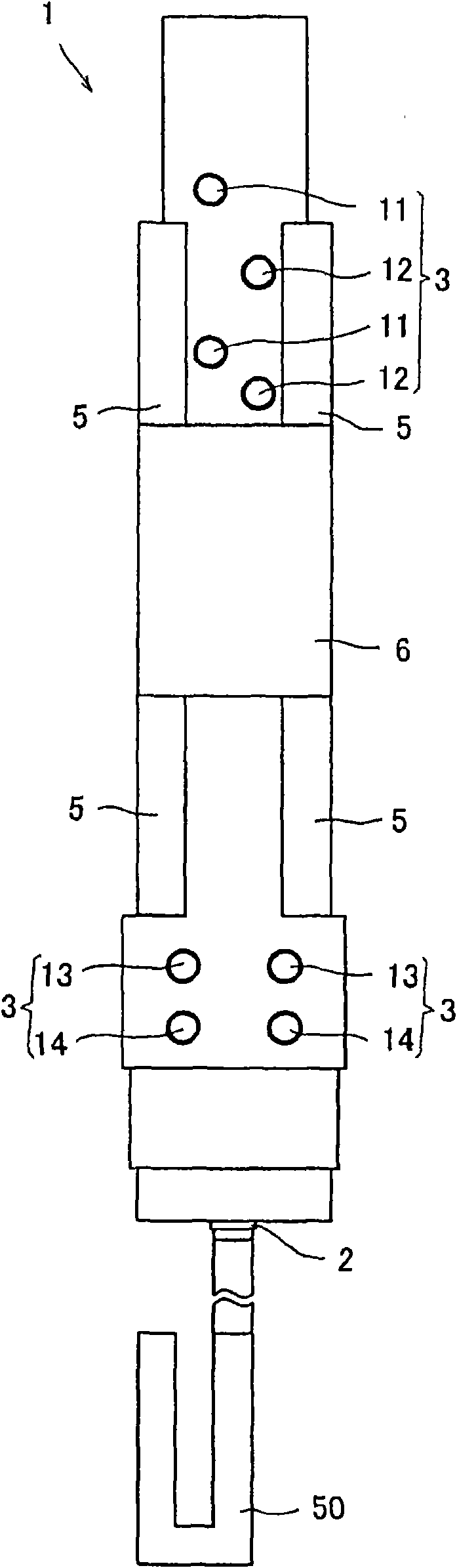

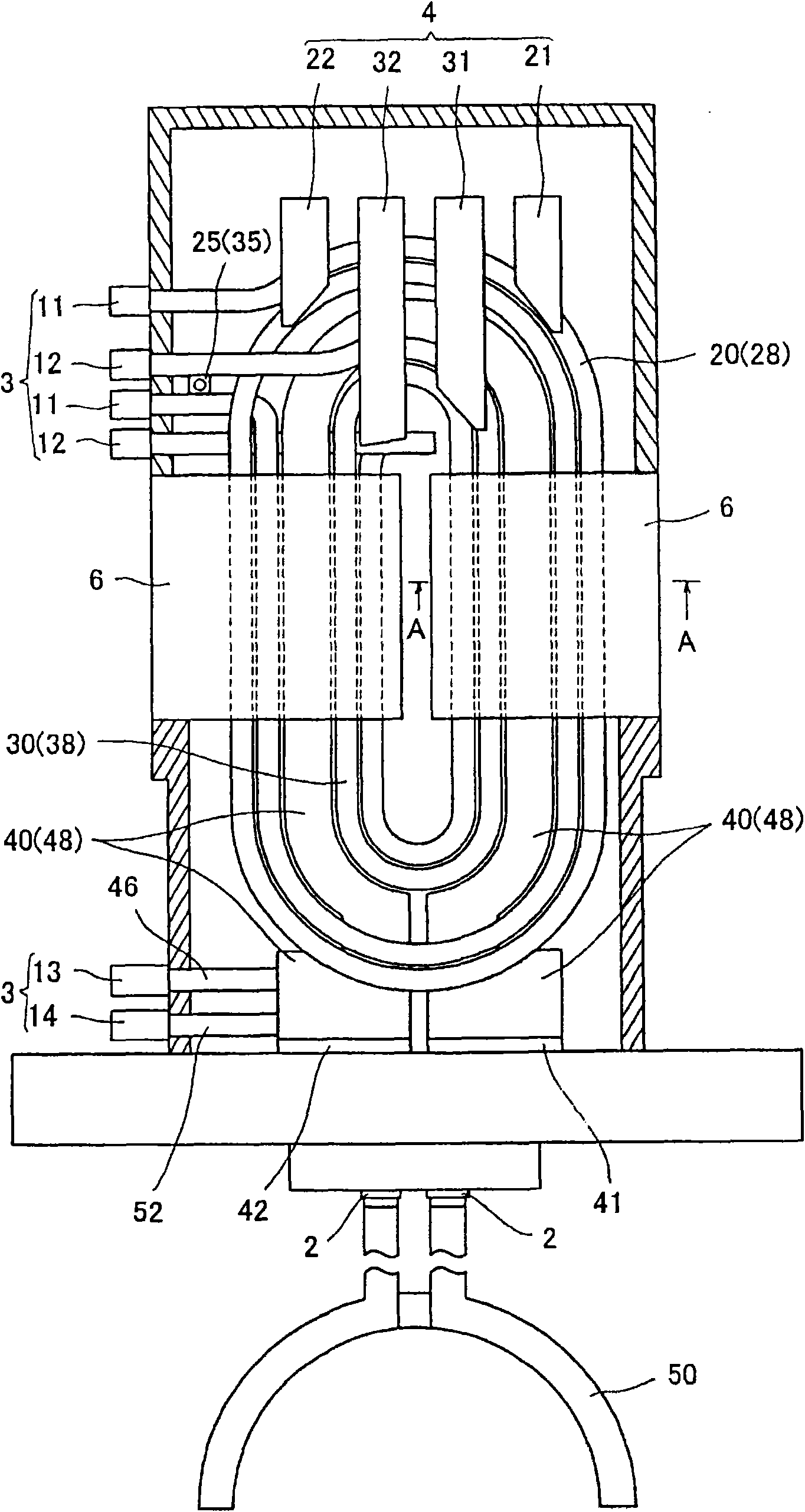

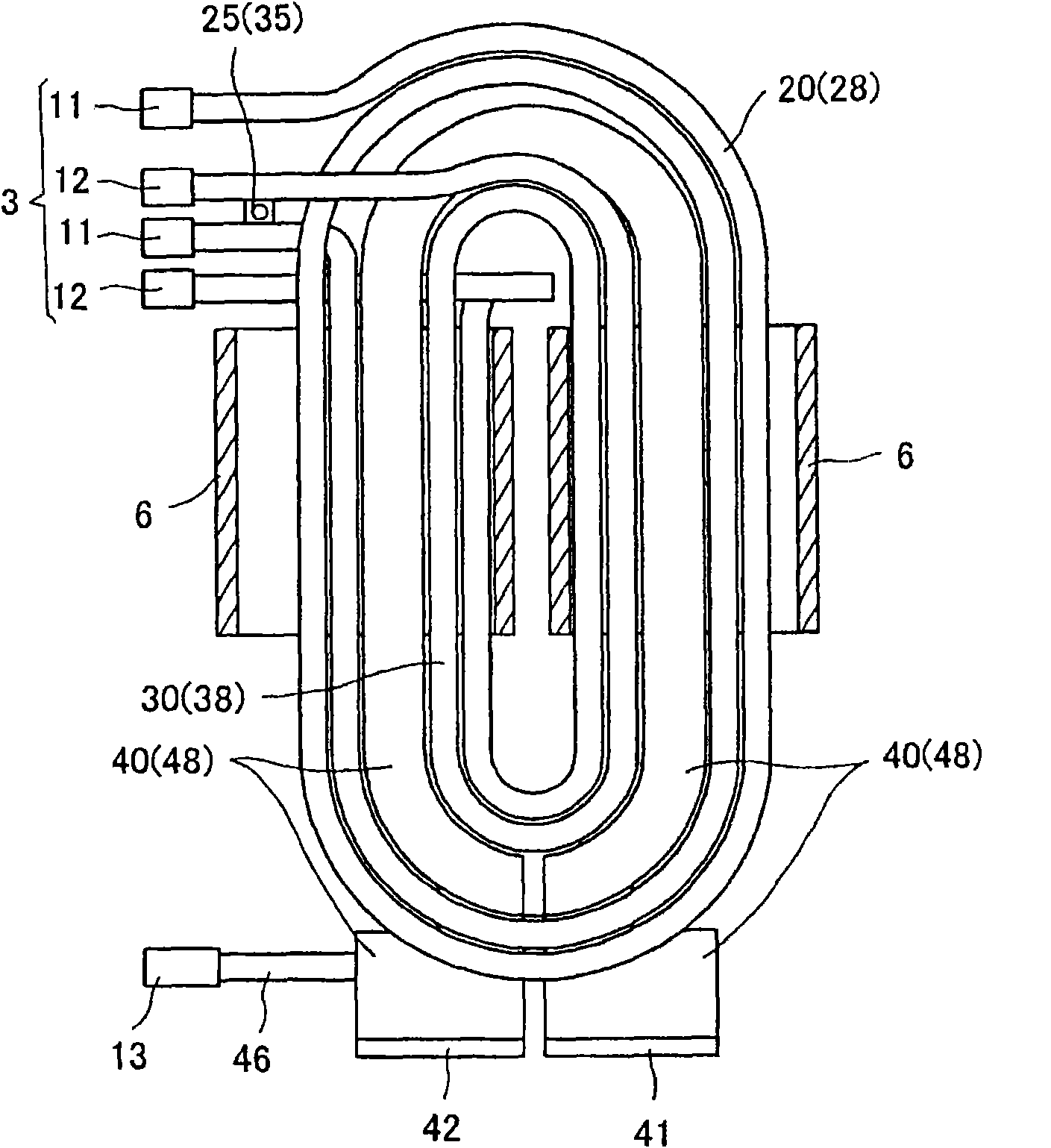

[0039] First, the configuration of the thin transformer 1 for high-frequency induction heating according to the embodiment of the present invention will be described. The thin transformer 1 for high-frequency induction heating is a device for outputting a high-frequency current to the induction heating coil 50, and is composed of two primary coils 20 and 30, a secondary coil 40, and the like (details will be described later). Such as figure 1 , 2 As shown, the thin transformer 1 for high-frequency induction heating is horizontally wide and thin, and has a high and deep structure. A thin transformer 1 for high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com