N-type jack contact element connector for matching and connecting 1-1/4 coaxial leakage cable

A technology for socket contacts and leaking cables, which is applied in the direction of contact parts, conductive connections, connections, etc., can solve the problems of parts processing and assembly difficulty, increased production cost of connectors, unsuitable installation and replacement, etc., to achieve electrical Excellent performance, reliable clamping of the outer conductor of the cable, and soft deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

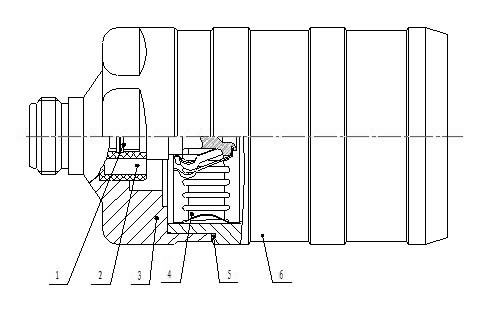

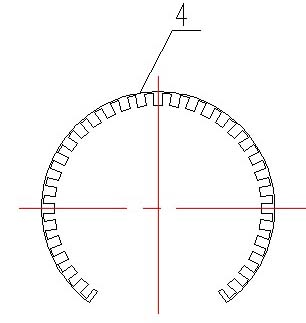

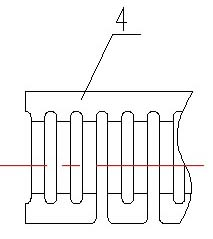

[0017] see figure 1 and Figure 4 , including plugged shell one 3 and shell two 6, shell one 3 is provided with insulator 2, and shell one 3 is provided with spring coil 4, spring coil 4 is set on the side of insulator 2, each two of spring coil 2 are independent The petals are combined into a "creep type", and a seal 5 is arranged between the spring ring 4 and the shell one 3. The spring coils for contacting the outer conductor adopt the "crenel-type" structure in the same city wall building. On the basis of providing stable overall holding force, each "crenel" is independent of each other. It solves the problem that when the cable is deflected, the positive pressure of the whole circle is kept equal. The existing "long trapezoidal" spring coil is bound by its chord length and cannot be extended because the upper belt and the lower belt are integrated. It causes the arch height to form destructive nonlinear deformation during compression deformation, and the positive press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com