Photonic crystal microcavity laser

A technology of photonic crystal microcavity and photonic crystal, applied in the structure of optical resonant cavity, structure of optical waveguide semiconductor, etc., can solve the problems of increased number of cavity modes, low Q value, large volume, etc., and achieve less number of microcavity modes , Improve the enhancement effect, the effect of large microcavity volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

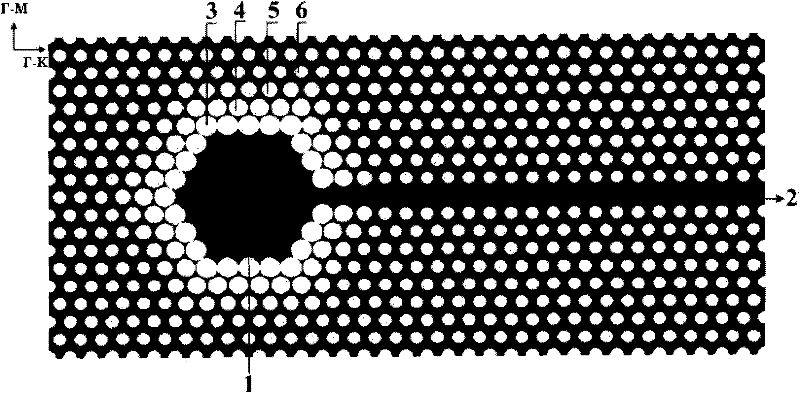

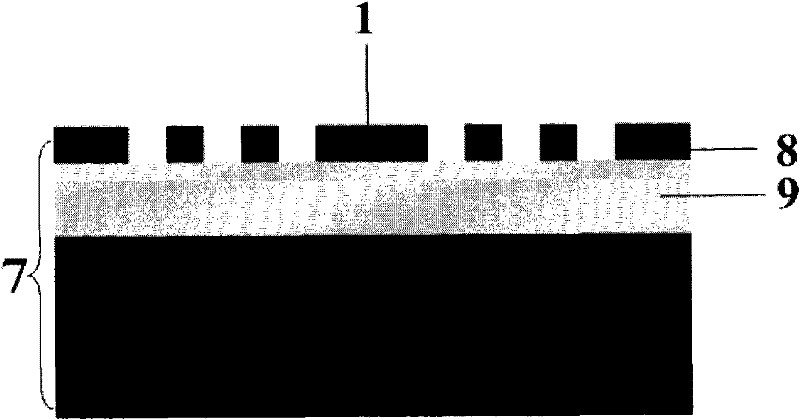

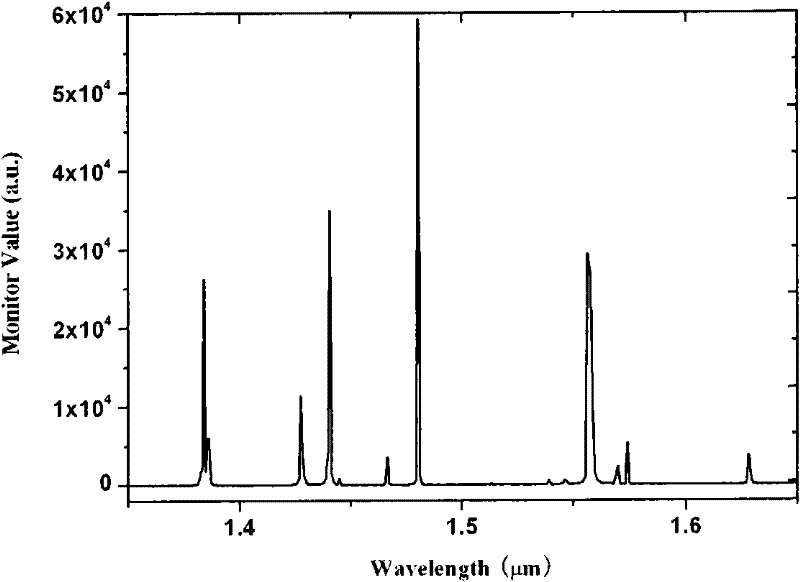

[0027] See attached figure 1 and 2 , the photonic crystal microcavity 1 of the photonic crystal microcavity laser in this embodiment is a complete two-dimensional flat triangular lattice air-hole photonic crystal on the top layer of silicon 8 of the SOI substrate 7, and removes the edges formed by several air holes in the middle A regular hexagonal H4 microcavity with a length of 4 lattice constants is implanted with erbium ions and oxygen ions into the photonic crystal microcavity 1, and an active region is formed after high temperature annealing. Starting from one end point of the hexagon of the photonic crystal microcavity 1, a row of air holes are removed along the direction of the photonic crystal Γ-K to form the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com