Method for measuring thickness of edge film of silicon wafer

An edge film, thickness measurement technology, applied in the direction of electric/magnetic thickness measurement, measurement device, electromagnetic measurement device, etc., can solve the problem of inaccurate edge film thickness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

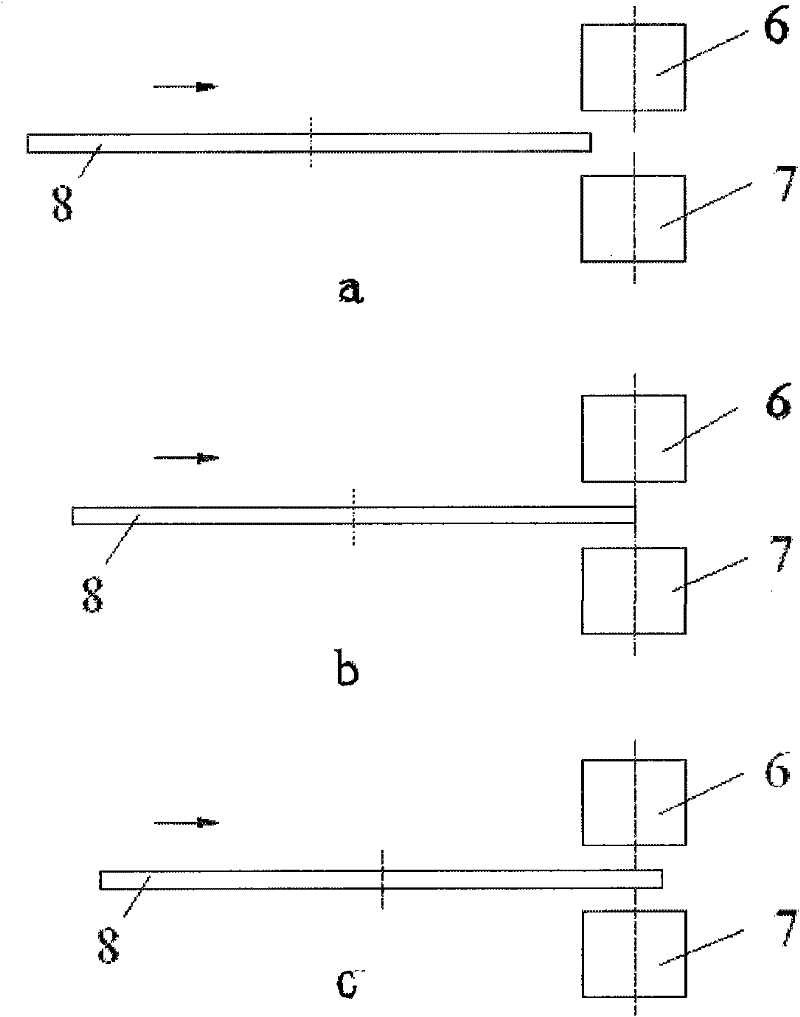

[0032] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

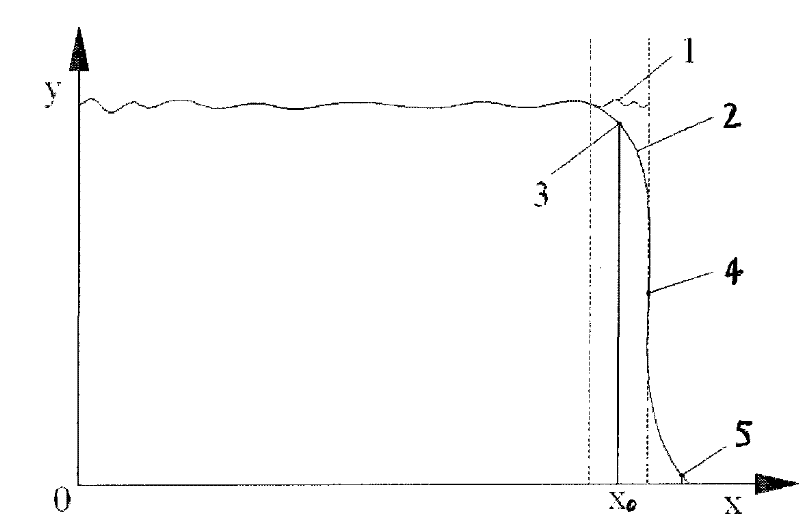

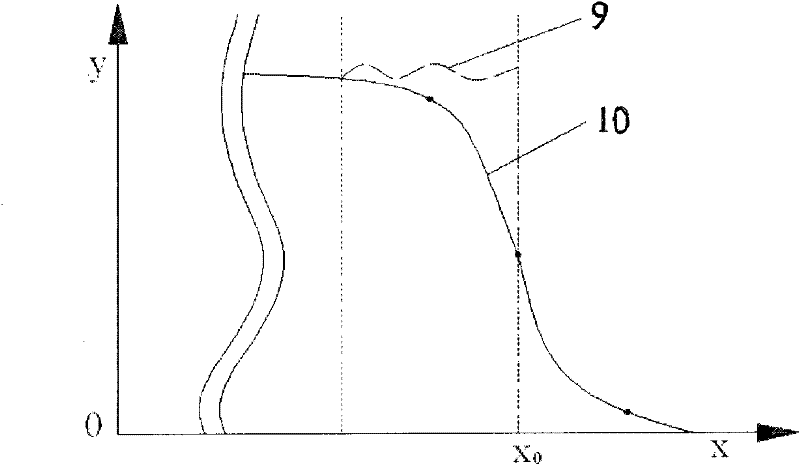

[0033] The principle of the above solution is to use a mathematical algorithm to obtain an accurate silicon wafer edge film thickness without changing the film thickness measurement hardware.

[0034] The mathematical model of the present invention is or x is the measured point, its range is x 0 -2D~x 0 Between, D is the diameter of the eddy current sensor, T m is the measured value of film thickness at point x, T r is the actual thickness value of film thickness at point x, x 0 film thickness edge point, d is the correction coefficient related to sensor size, shape, working distance, etc., t is the integral variable in The value between, film thickness measurement value T m It can be measured by the eddy current sensor, and the d obtained after calibration and the measured T m And the coordinates of point x are substituted into the model to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com