Fiber laminated body structure with fabric touch and preparation method thereof

A laminate and fiber layer technology, applied in the field of fiber laminate structure and its preparation, can solve problems such as complicated manufacturing process, poor structural strength, and inability to provide fabric touch, so as to simplify the preparation procedure, increase added value, and improve Effect of Basic Structural Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

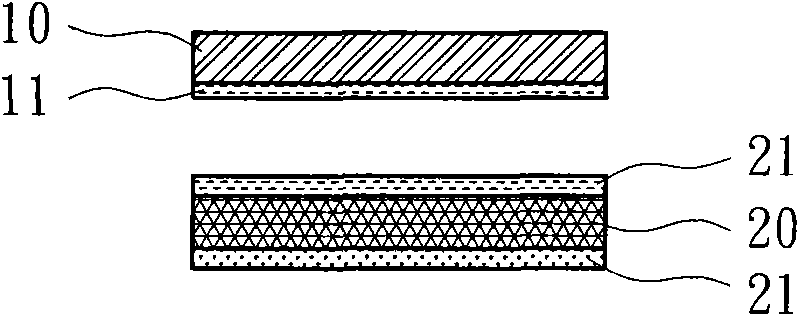

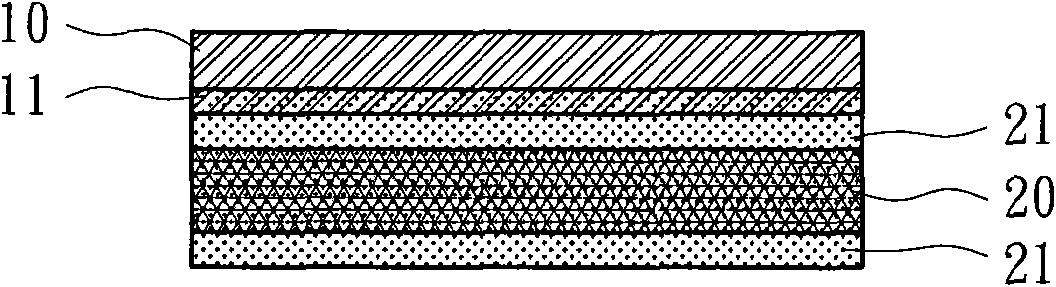

[0051] The present invention is a fiber laminate structure with fabric touch and its preparation method. In the specific embodiment of the fiber laminate structure of the present invention and its structure shown in the accompanying drawings, all about front and back, left and right, References to top and bottom, upper and lower, and horizontal and vertical are used for convenience of description only, and do not limit the invention, nor limit its structure to any position or spatial orientation. The dimensions specified in the drawings and the specification can be changed according to the design and requirements of the specific embodiments of the present invention within the protection scope of the present invention.

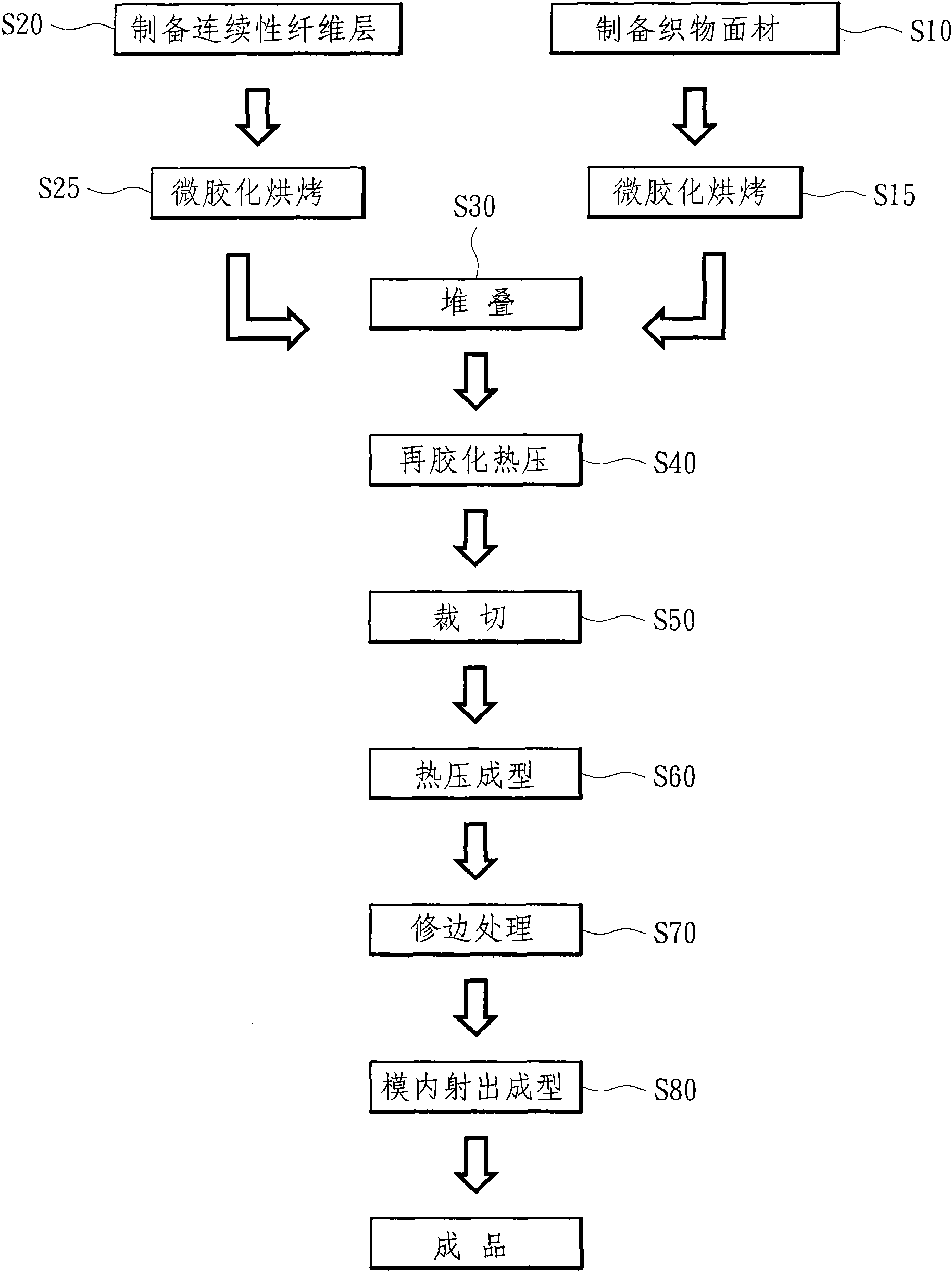

[0052] Regarding the preparation method of the fiber laminate structure with fabric touch of the present invention, as attached figure 1 As shown, the steps include: a fabric surface material preparation S10, a continuous fiber layer preparation S20, a stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com