Polygonal brake device

A braking device, polygonal technology, applied in the direction of the hoisting device, etc., can solve the problems of the spring arrangement of the brake being too tight or interfering, the design arrangement space is small, and the material waste, so as to reduce the cost and material waste, The parallelism is easy to guarantee and the effect of economical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

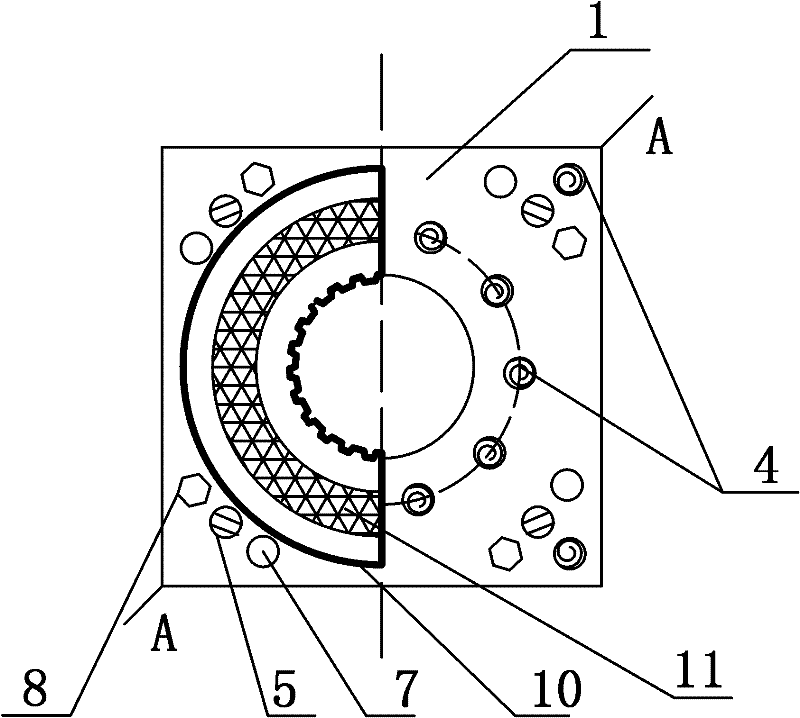

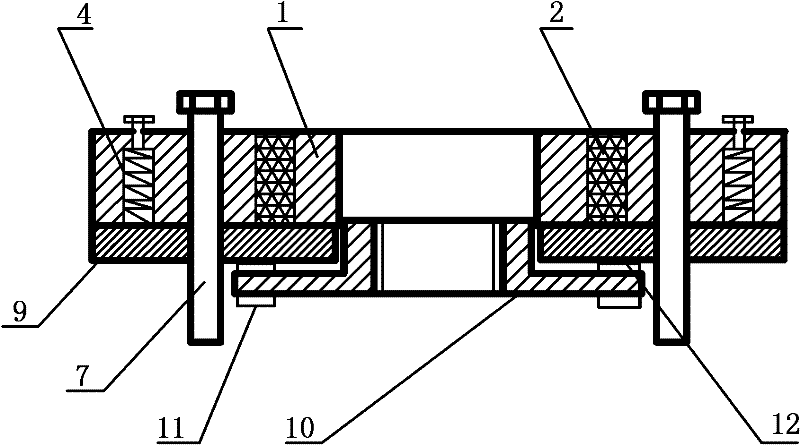

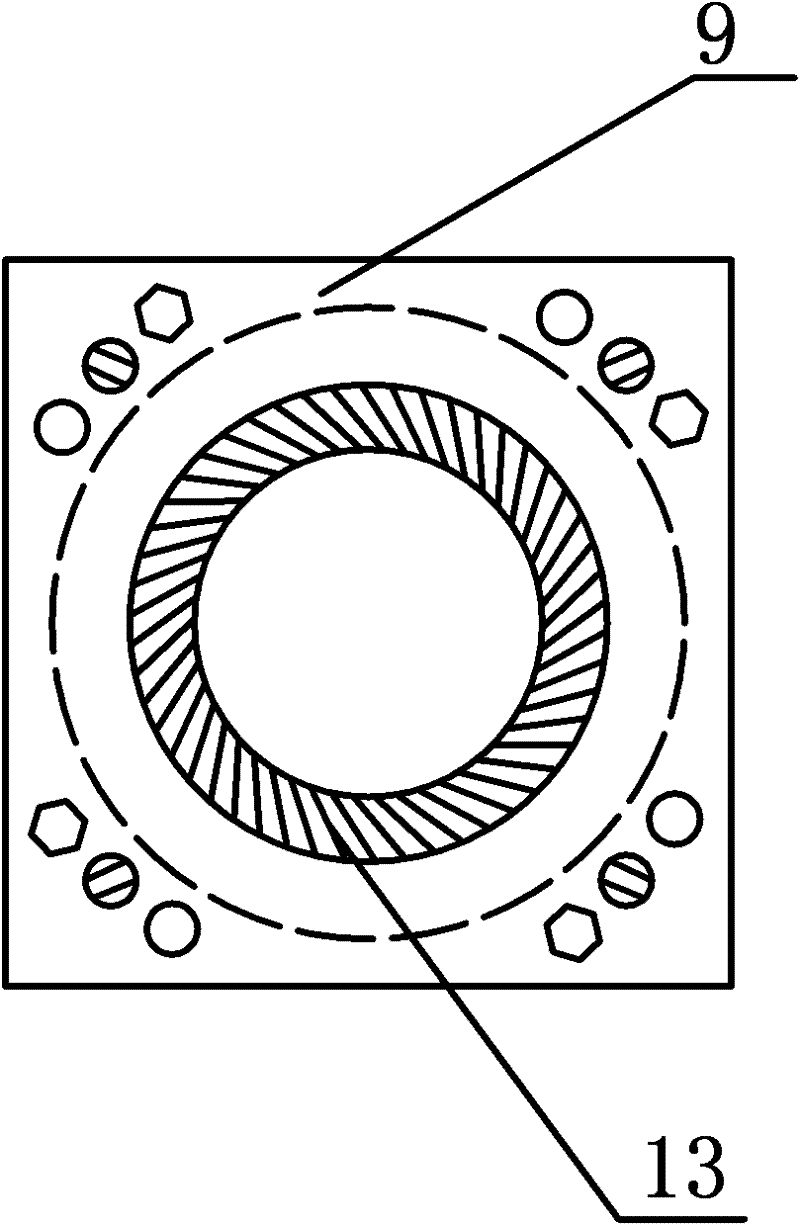

[0022] Example 1. A polygonal detent such as figure 1 and figure 2 As shown, it includes an iron core assembly. The iron core assembly is provided with a guide pin 5 connected to the armature 9. A brake disc 10 is clamped between the armature 9 and the traction machine. Friction plates 11 are provided on both sides of the brake disc 10, and It is connected with the rotating shaft of the traction machine through a spline, and it is characterized in that: the iron core assembly includes a polygonal (can be square) iron core, and a ring coil 2 is arranged in the slot on the iron core, and the corresponding iron core assembly The armature 9 is also polygonal (square), and the connection structures between the iron core 1 and the armature 9 are all arranged on the four corners of the polygonal (square). The connection structure includes a guide pin 5 , a fixing bolt 7 passing through the iron core 1 and the armature 9 to connect with the traction machine, and an anti-jack bolt 8...

Embodiment 2

[0023] Example 2. A polygonal detent such as figure 1 and figure 2 As shown, it includes an iron core assembly. The iron core assembly is provided with a guide pin 5 connected to the armature 9. A brake disc 10 is clamped between the armature 9 and the traction machine. Friction plates 11 are provided on both sides of the brake disc 10, and It is connected with the rotating shaft of the traction machine through a spline, and it is characterized in that: the iron core assembly includes a polygonal (square) iron core, and a ring coil 2 is arranged in the slot on the iron core, and the armature 9 corresponding to the iron core assembly It is also a polygon (square), and the connection structures between the iron core 1 and the armature 9 are all arranged on the four corners of the polygon (square). The connection structure includes a guide pin 5 , a fixing bolt 7 passing through the iron core 1 and the armature 9 to connect with the traction machine, and an anti-jack bolt 8 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com