BGA (ball grid array) coplanarity measuring system based on projection Moire principle

A measurement system and coplanarity technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to adjust and affect the grating, and achieve the effect of good contrast, improved measurement accuracy, measurement accuracy and measurement speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. In this embodiment, the object to be tested is a BGA solder ball, but it can also be substrate flatness in other packaging forms.

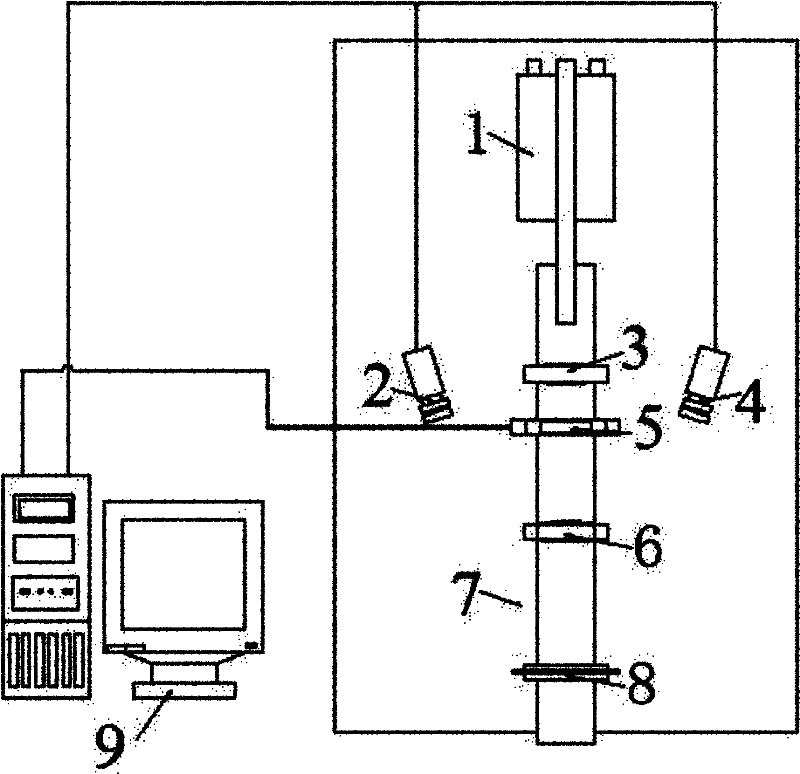

[0024] Projection Moiré coplanarity three-dimensional measurement system of the present invention comprises cold light source 1, two CCD cameras 2 and 4 on the left and right, collimator lens 3, LCD liquid crystal panel 5, projection lens 6, optical platform 7, high-precision mobile platform 8 and computer9.

[0025] The collimator lens 3 , the LCD panel 5 , the projection lens 6 and the high-precision mobile stage 8 are clamped and fixed on the optical platform 7 sequentially and linearly.

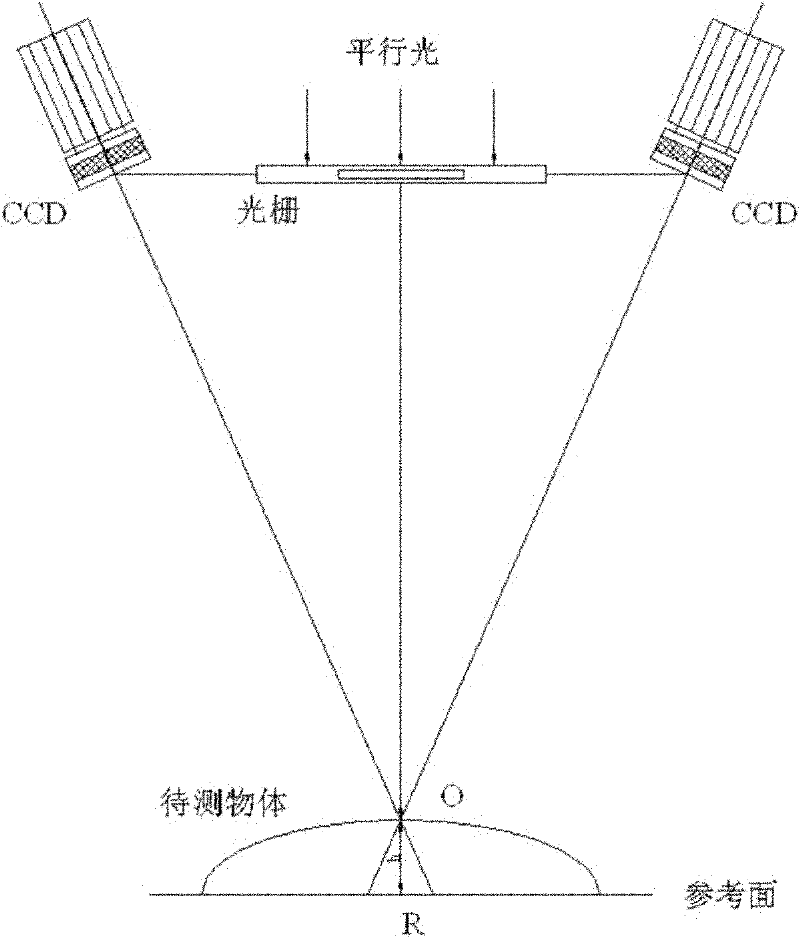

[0026] The cold light source 1 produces a beam of parallel light through a collimator lens 3 and irradiates it onto the LCD panel 5 , and a sinusoidal fringe pattern is generated on the LCD panel 5 , and the sinusoidal fringe patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com