Gear impact bend simulation test method and device

A technology of test device and test method, which is applied in the direction of machine gear/transmission mechanism testing, measuring device, and testing material strength by applying repetitive force/pulse force, etc., can solve the problem of inconvenient installation of samples, and achieve simple structure and accurate installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

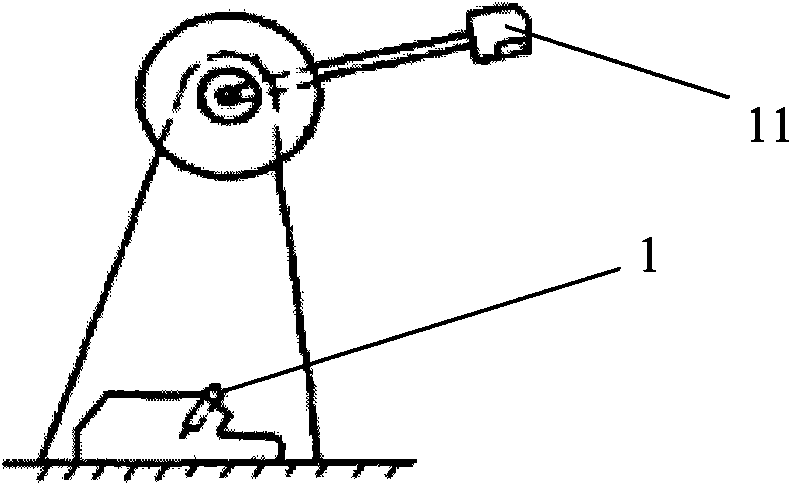

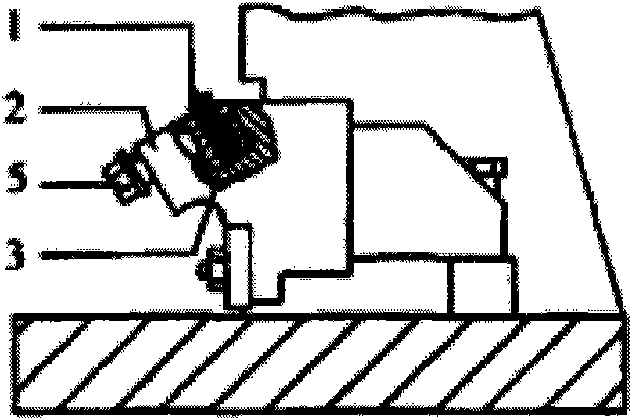

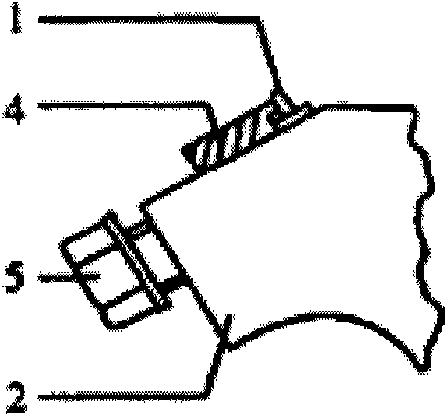

[0031] Figure 4 It shows a device for simulating the gear bending test of the present invention, including a bracket 10, a pendulum 11 whose rotation axis is set on the upper end of the bracket, a hammer head is provided at the end of the pendulum 11, and a hammer head is arranged along the hammer head. The knife edge 111 that swings radially extends is provided with the sample fixing anvil 20 (such as Figure 5 As shown), the bending punch sample is fixed on the running track of the pendulum knife edge through the fixed anvil 20. In this embodiment, the sample 1 is set at the lowest point of the pendulum knife edge 111 hem. The fixed anvil 20 is provided with a sample clamping groove 201 on the tangential plane of the impact point along the circular movement of the hammer head (in this embodiment, on the tangential horizontal plane of the impact point), and the bending punching sample 1 is matched and arranged on the The sample is held in the slot 201 and fixed by the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com