Plate oxygen sensor and preparation method thereof

An oxygen sensor and chip technology, which is applied in the field of chip oxygen sensor and its preparation, can solve the problems of low thermal shock resistance, difficulty in heterogeneous combination, poor sealing of oxygen sensor, etc., and achieve high thermal shock resistance and sealing Good, reduced size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a chip oxygen sensor, which includes superimposing a heating body and an oxygen measuring body, hot pressing and sintering to obtain the chip oxygen sensor;

[0023] The heating body includes a heater substrate, two insulating layers above the heater substrate and a heating electrode clamped between the two insulating layers; the oxygen measuring body includes a reference gas substrate, a Oxygen measuring layer and porous protective layer;

[0024] The area of the insulating layer is smaller than the area of the heater substrate, the area of the insulating layer is smaller than the area of the reference gas substrate, and the edge of the heater substrate is in contact with the edge of the reference gas substrate.

[0025] In the present invention, the preparation method of the chip oxygen sensor is a co-firing method known to those skilled in the art, which specifically includes the following steps:

[0026] 1) Take...

Embodiment 1

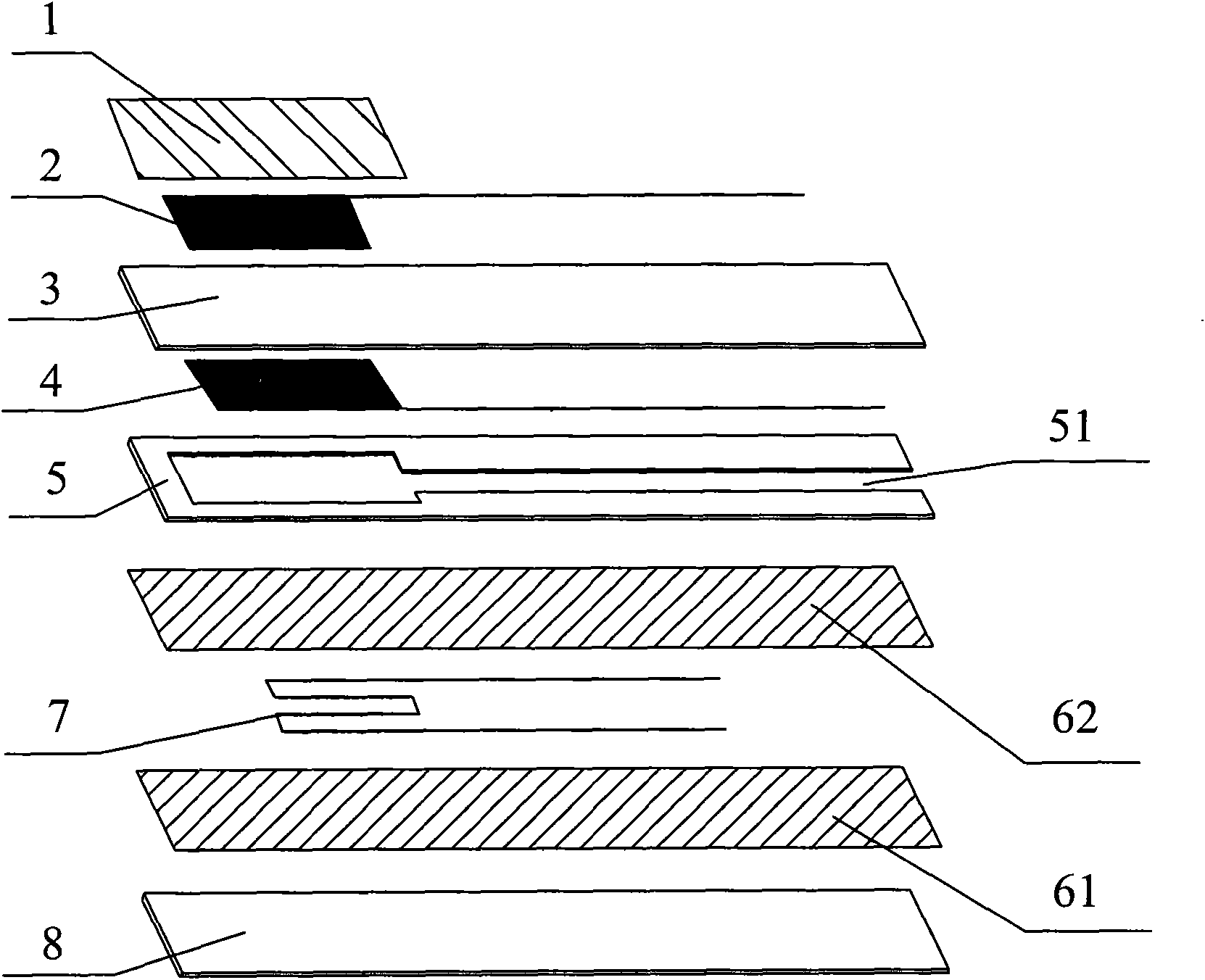

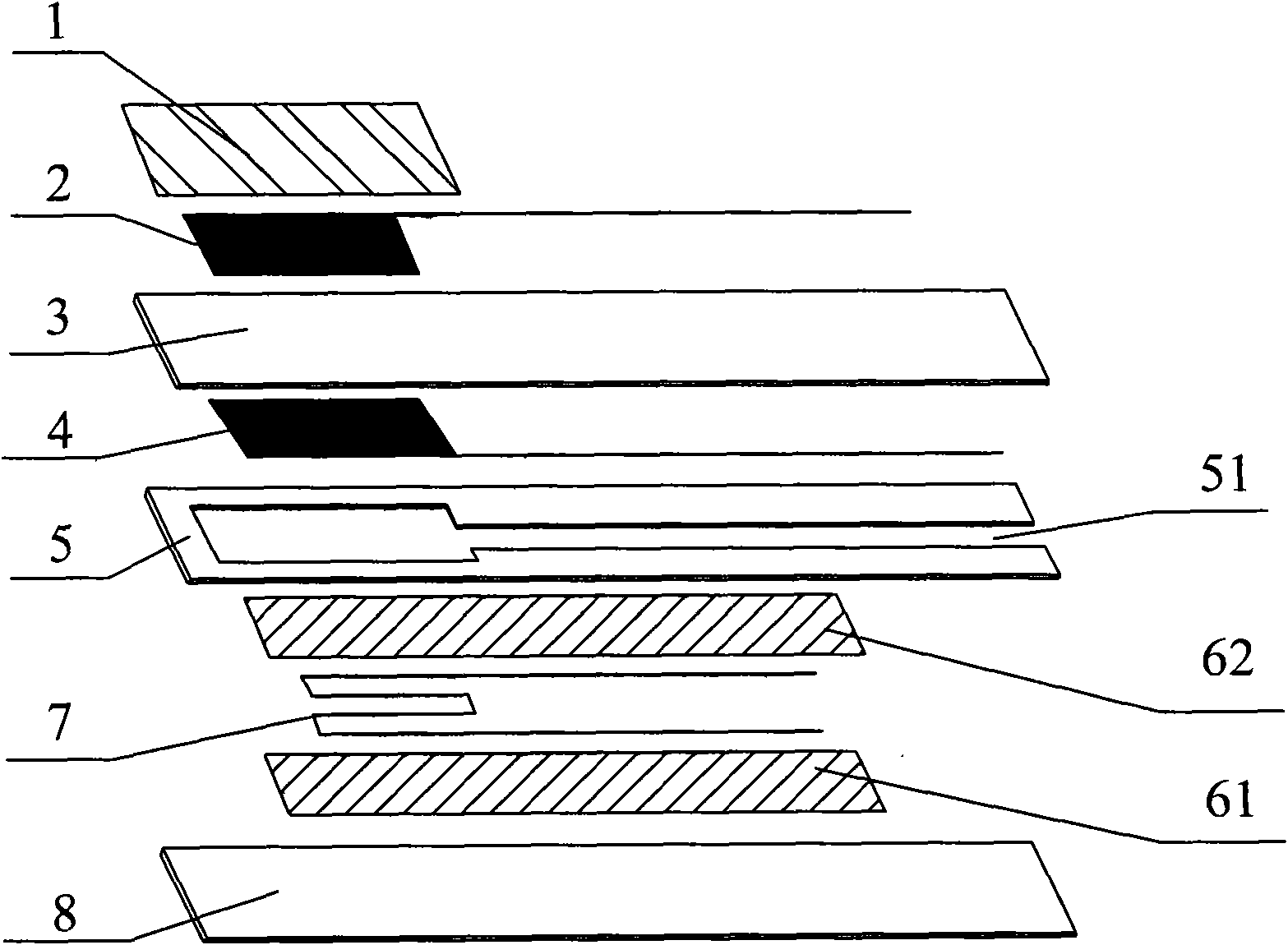

[0039] The invention provides a chip oxygen sensor, the chip oxygen sensor includes a heating body and an oxygen measuring body on the upper part of the heating body, such as figure 2As shown, the heating body includes a heater substrate 8, an insulating layer 61, a heating electrode 7, and an insulating layer 62 from bottom to top; the oxygen measuring body includes a reference gas substrate 5 and an internal electrode 4 from bottom to top. , zirconia sensitive substrate 3, external electrode 2 and porous protective layer 1, wherein, internal electrode 4, zirconia sensitive substrate 3 and external electrode 2 constitute the oxygen measuring layer; the area of insulating layers 61, 62 is smaller than that of heater substrate 8 The area of the insulating layers 61 and 62 is smaller than the area of the reference gas substrate 5 .

[0040] The insulating layer 61 , the heating electrode 7 and the insulating layer 62 are formed on the heater substrate 8 by a thick film sc...

Embodiment 2

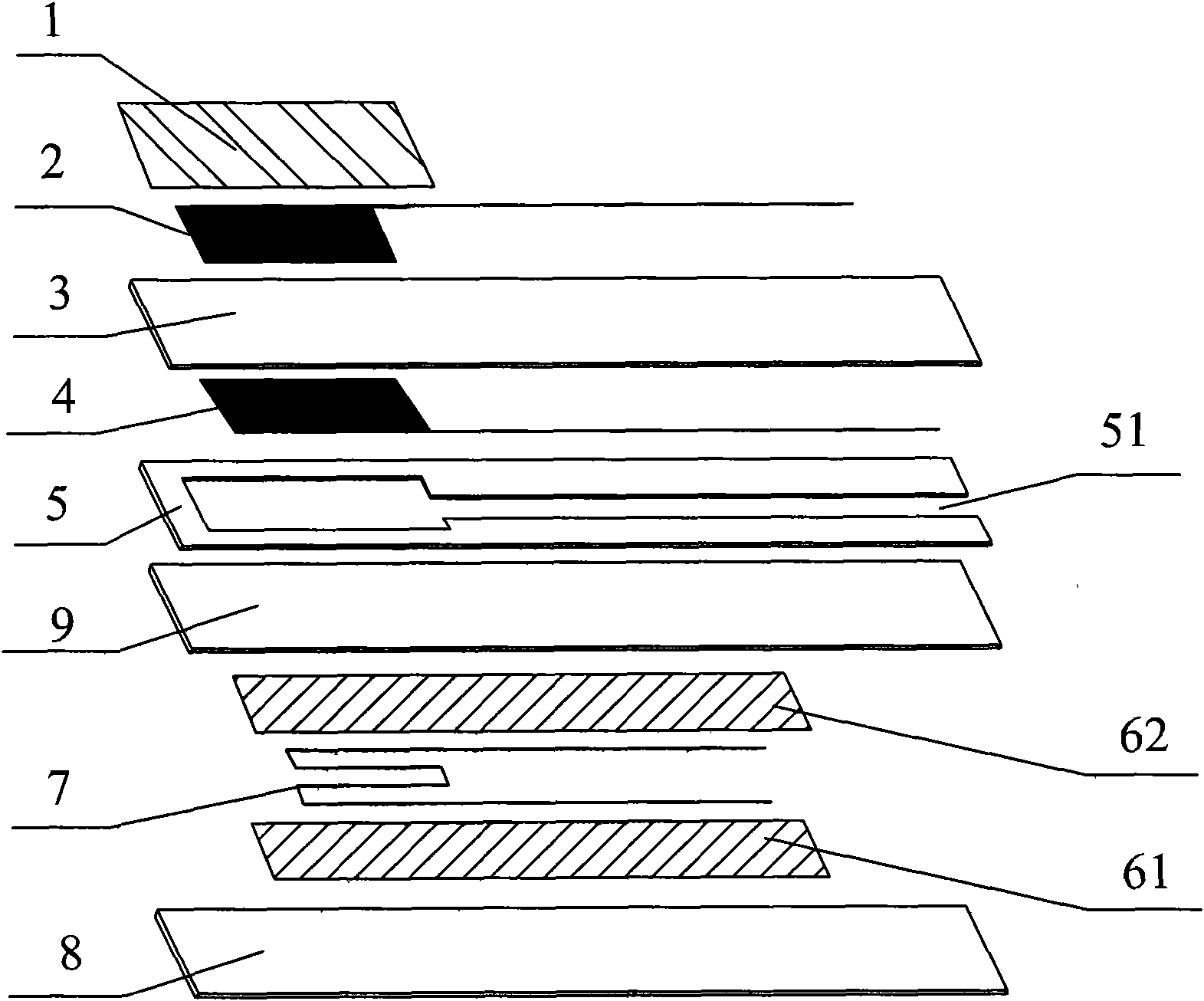

[0043] Such as image 3 As shown, the chip oxygen sensor of the second embodiment of the present invention is similar to that of the first embodiment, and its difference from embodiment 1 is that a zirconia transition layer is also included between the insulating layer 62 and the reference gas substrate 5 9. The area of the zirconia transition layer 9 is larger than the area of the insulating layer 62 . The zirconia transition layer 9, on the one hand, is homogeneously combined with the upper reference gas substrate 5, and has a high degree of bonding; on the other hand, the contact area between the zirconia transition layer 9 and the insulating layer 62 is larger than that of the insulating layer 62 in Example 1. Therefore, the zirconia transition layer 9 improves the bonding tightness between the insulating layer 62 and the reference gas substrate 5 . The obtained chip oxygen sensor has good sealing performance and high thermal shock resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com