Explosion-proof sensor

一种传感器、传感器元件的技术,应用在防爆传感器领域,能够解决制造过程复杂等问题,达到减轻张力、防止金属销钉弯曲的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

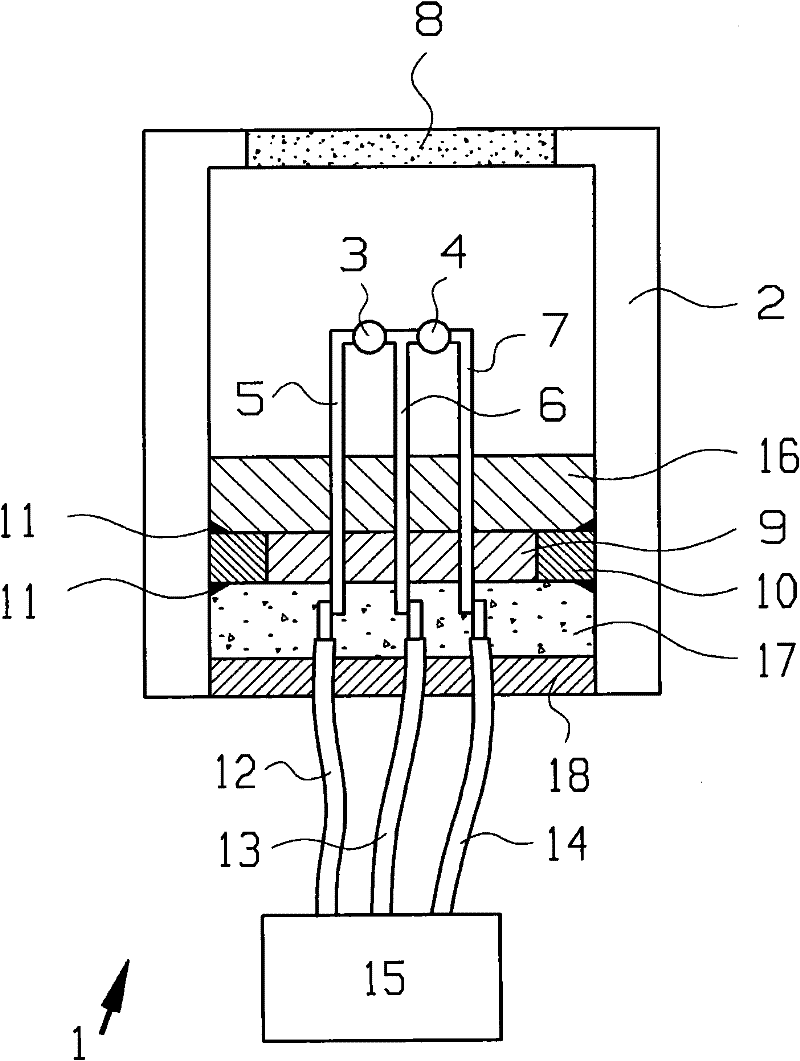

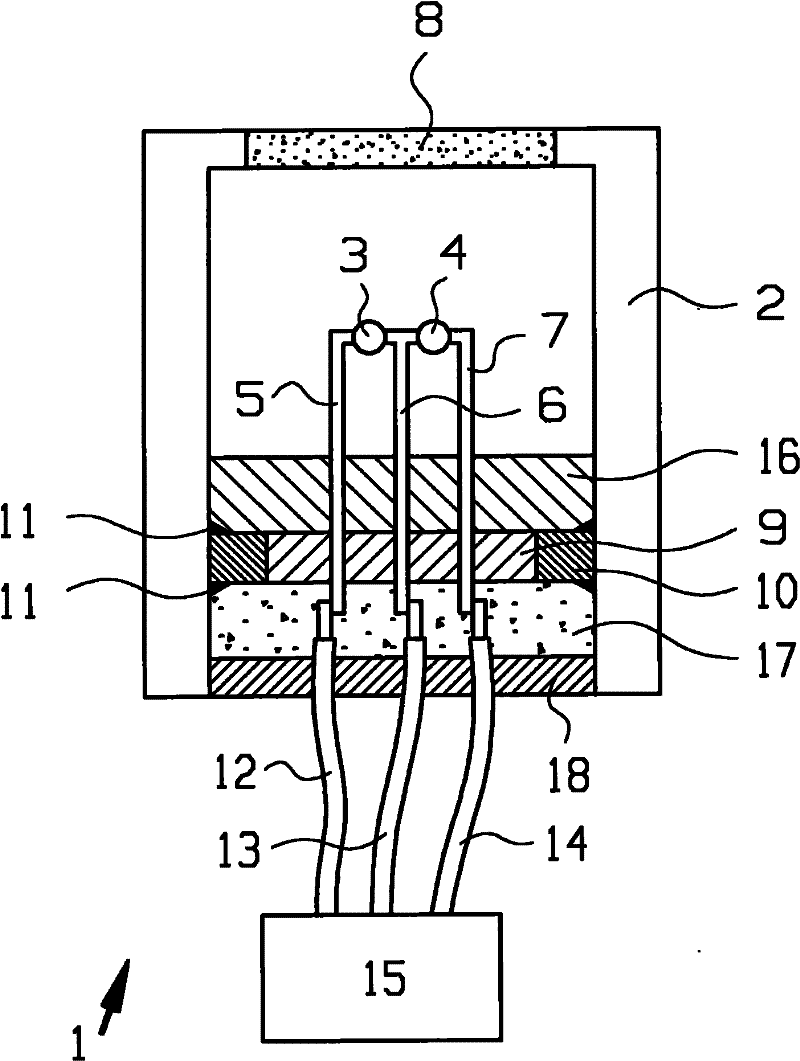

[0020] The single FIGURE shows a longitudinal sectional view of a gas sensor 1 in which a catalytically active sensor element 3 and a catalytically inactive sensor element 4 are fastened to metal pins 5 , 6 , 7 in a sensor housing 2 . For the intake air, the upper side of the sensor housing 2 is closed in a known manner with a porous, gas-permeable disk made of sintered metal material. The metal pins 5, 6, 7 are accommodated by a flat glass insert 9, wherein the glass insert 9 is surrounded by an annular metal base 10, with which a gas-tight seal with the sensor housing 2 is established by means of weld seams 11. connect. The free ends of the metal pins 5 , 6 , 7 on the underside of the glass insert 9 are provided with input lines 12 , 13 , 14 which establish the connection to the evaluation unit 15 . On the top and bottom of the glass insert 9 there is a cast / injection part 16 , 17 each made of ceramic material with a thickness of 6 mm. The first cast / injection part 17 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com