Method for manufacturing multilayer printed circuit board (PCB)

A technology for printed circuit boards and manufacturing methods, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of large inner layer copper thickness, unrestricted flow, poor uniformity of board thickness, etc., to improve product yield and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

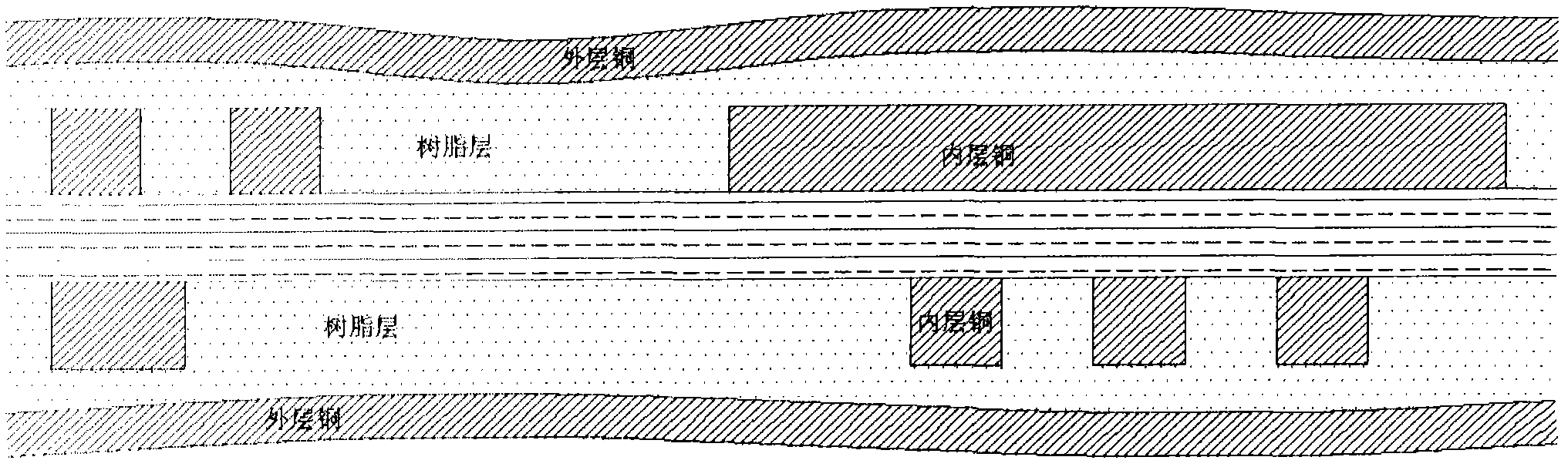

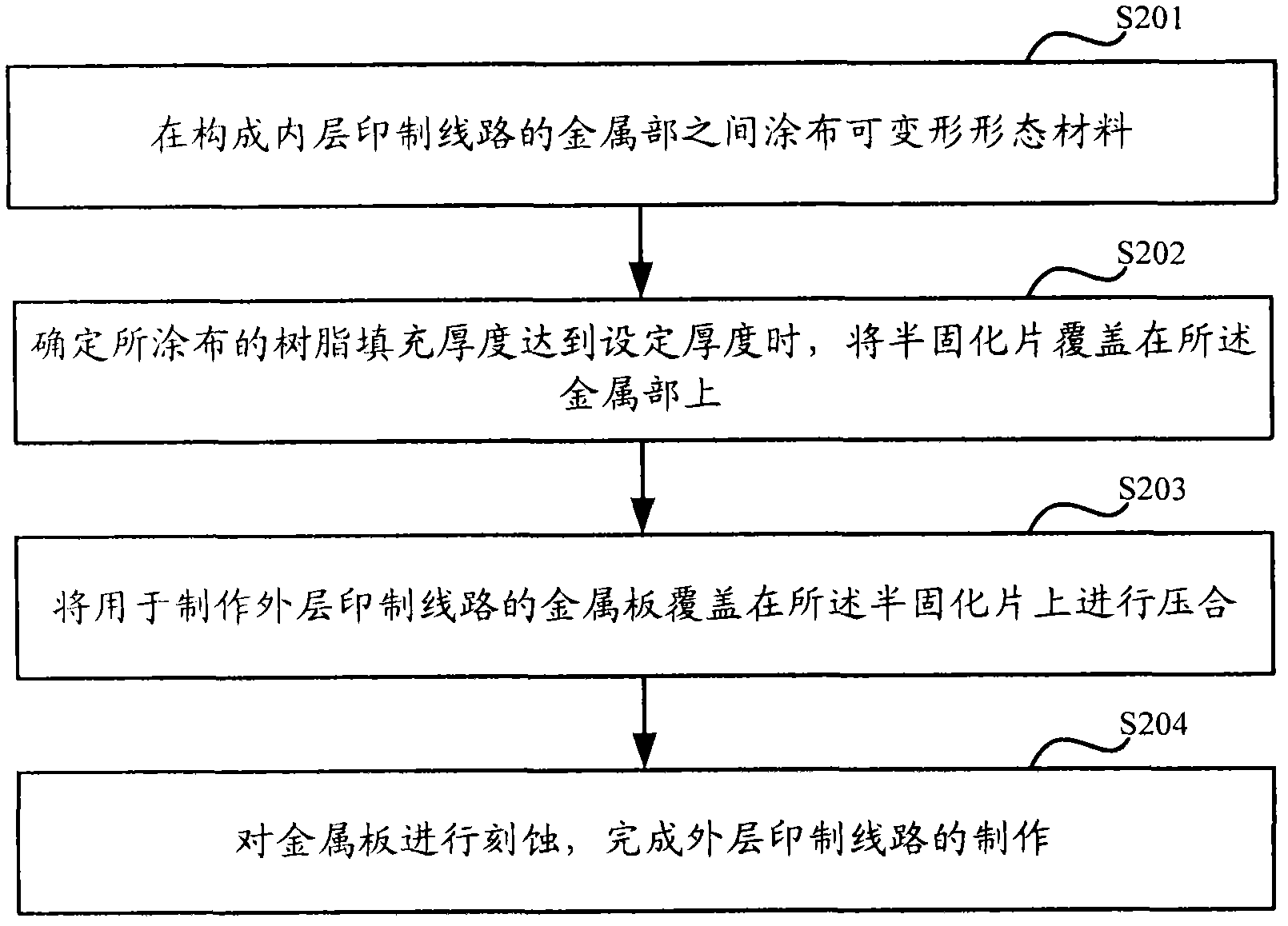

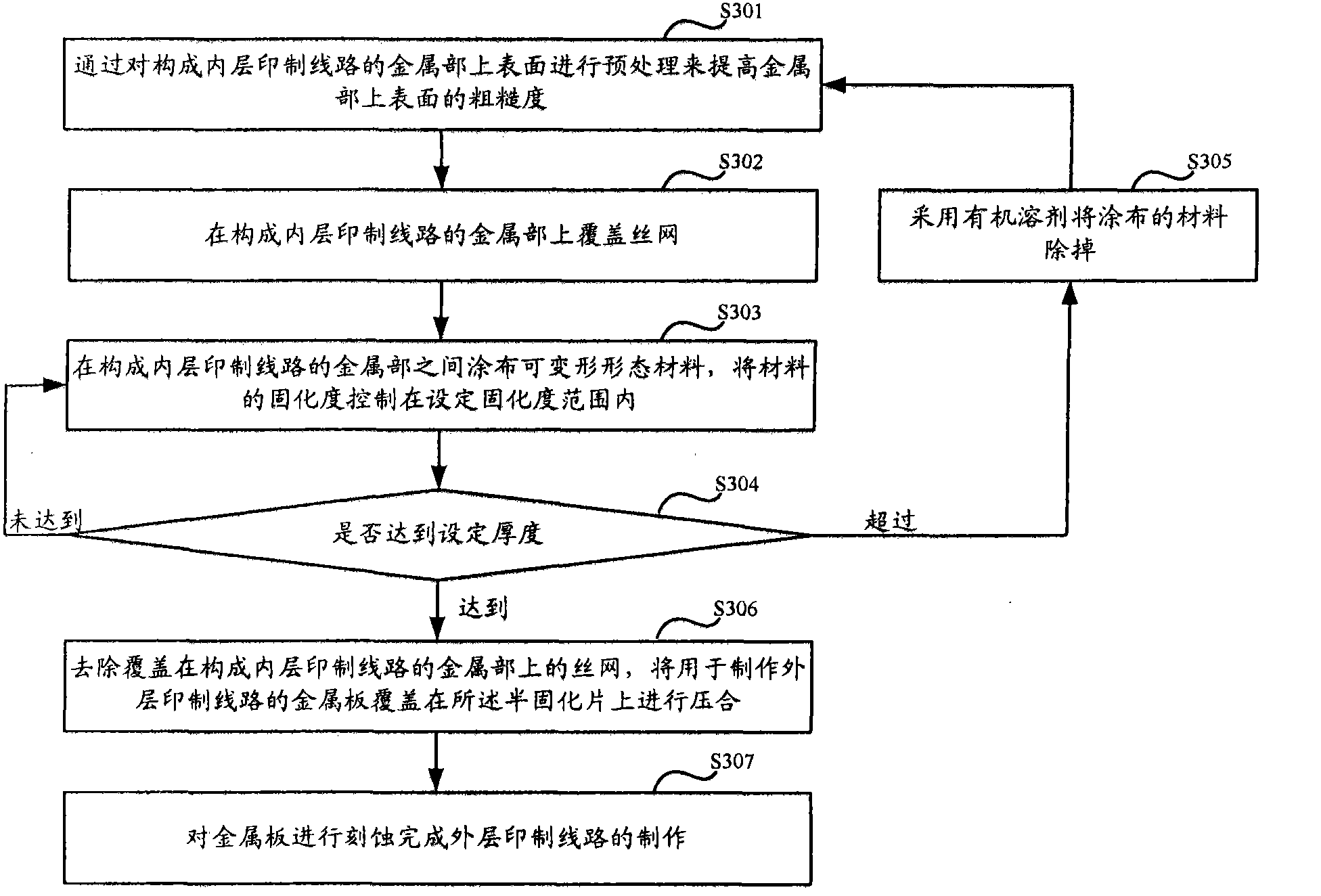

[0035] The invention provides a method for manufacturing a multilayer printed circuit board, which is characterized in that it comprises:

[0036] Coating a deformable form material between the metal parts constituting the inner printed circuit;

[0037] When it is determined that the filling thickness of the applied material reaches a set thickness, cover the prepreg on the metal part, and the set thickness does not exceed the thickness of the metal part constituting the inner printed circuit;

[0038] Covering the metal plate for making the outer printed circuit on the prepreg for pressing;

[0039] The metal plate is etched to complete the fabrication of the outer printed circuit.

[0040] Preferably, in each embodiment of the present invention, the deformable material can be semi-solid material, fluid material, liquid material or other deformable material, so that these materials can be filled in the required space . More preferably, these materials can be cured under s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com