A Dummy Filling Method Based on the Unified Framework of Sequential Quadratic Programming

A technology of sequence quadratic programming and filling method, which is applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., to achieve the effect of high estimation accuracy and high filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

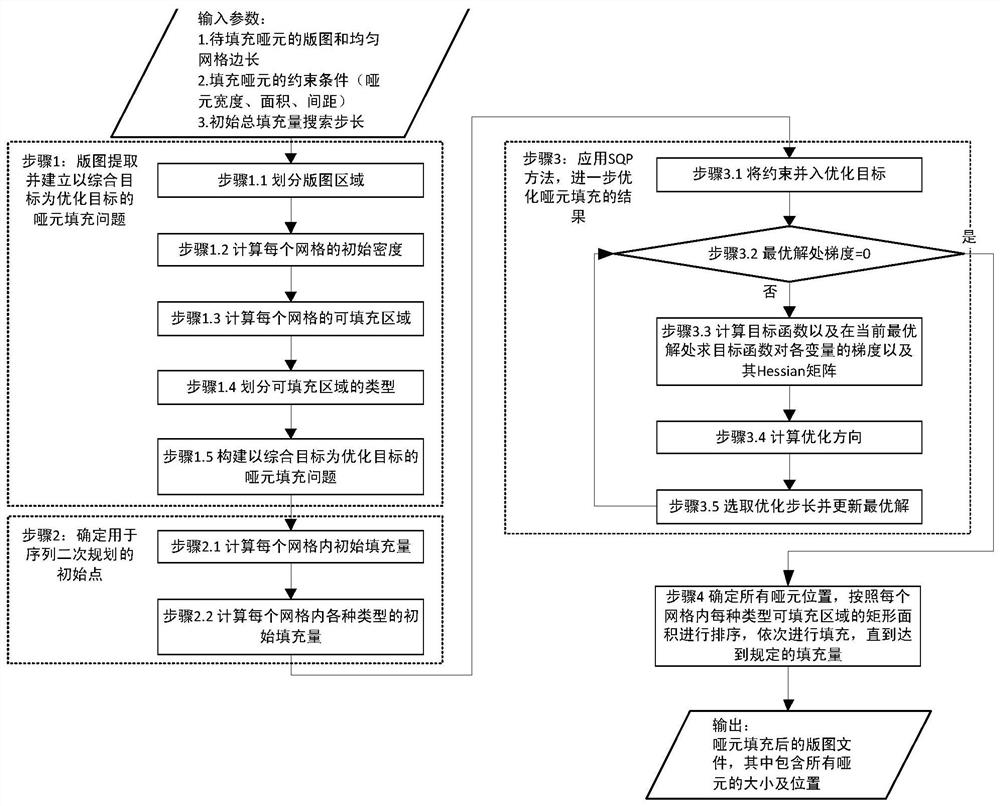

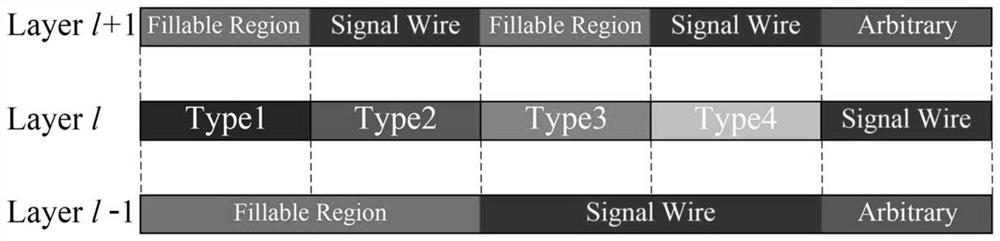

Method used

Image

Examples

Embodiment Construction

[0093] In order to make the objects, features and advantages of the present invention more obvious and understandable, the present invention will be further described below through specific examples.

[0094] This experiment is to verify the effectiveness of the unified chemical mechanical polishing process dummy filling method without model simplification proposed by the present invention. The experimental test cases and scoring standards are all from the literature [13] experimental test layout information and its corresponding scoring parameters As shown in Table 1 [13].

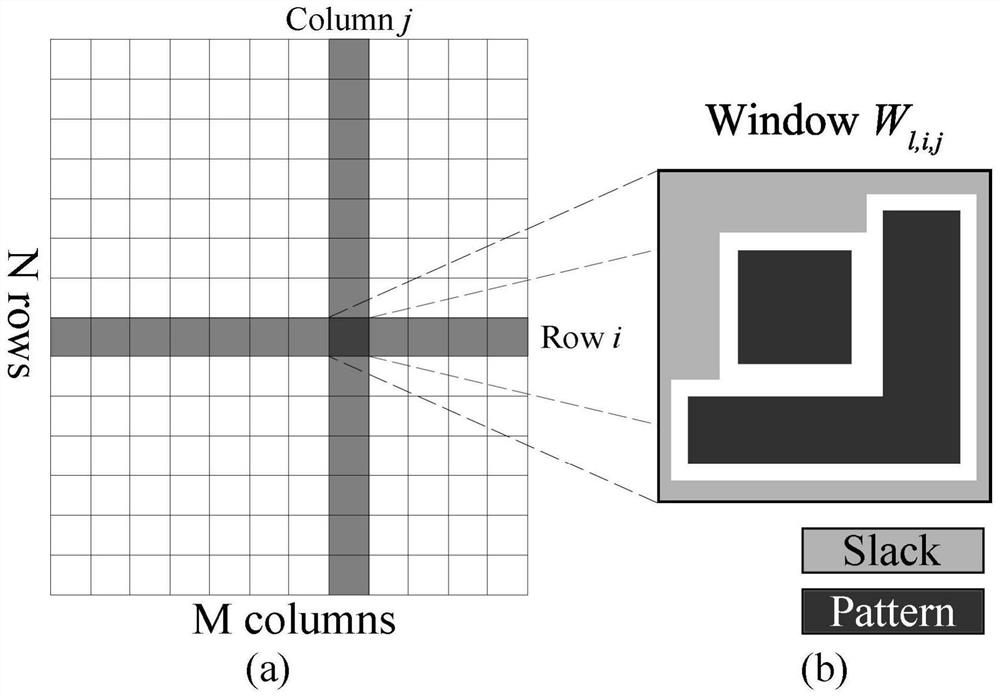

[0095] Adopt the dummy cell filling method proposed by the present invention, at first need to divide the whole layout, in this implementation example, divide the grid side length a=20 μ m, the minimum dummy cell width w m =32nm, the smallest dummy area a m =4800nm 2 , the distance between the smallest dummy and dummy or signal line s m =32nm, initial total filling amount search step size d=0.005.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com