Metal gate and manufacturing method thereof

A manufacturing method and metal gate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting metal gate resistance, small process adjustment window, and affecting device performance, so as to improve device performance, Reduce the difficulty of filling and improve the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

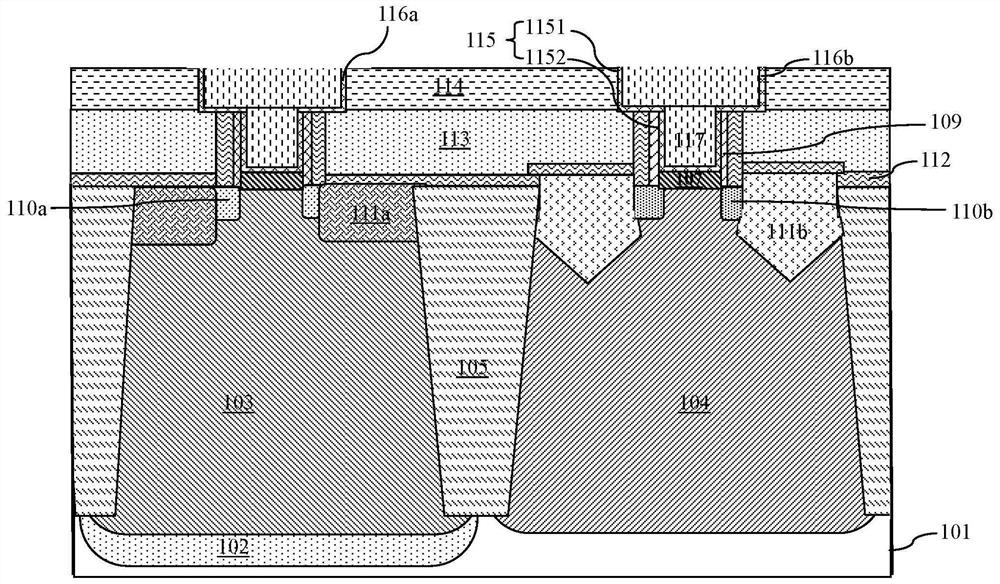

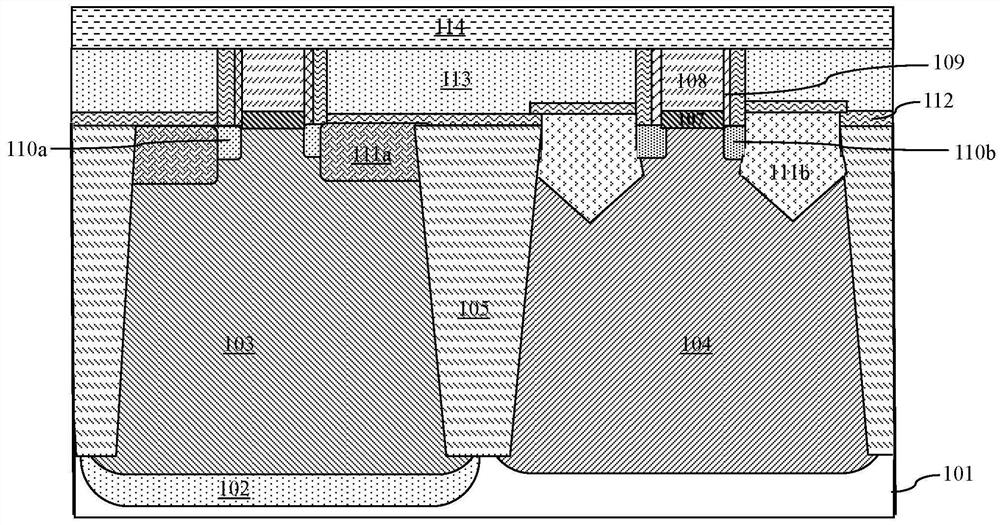

[0044] like figure 1 As shown, it is a schematic diagram of the structure of the metal gate according to the embodiment of the present invention; in the metal gate of the embodiment of the present invention, the gate structure formed by the superposition of the gate dielectric layer 107 and the metal gate is formed in the gate groove 115, and the gate groove The groove 115 is divided into a bottom groove 1152 and a top groove 1151 .

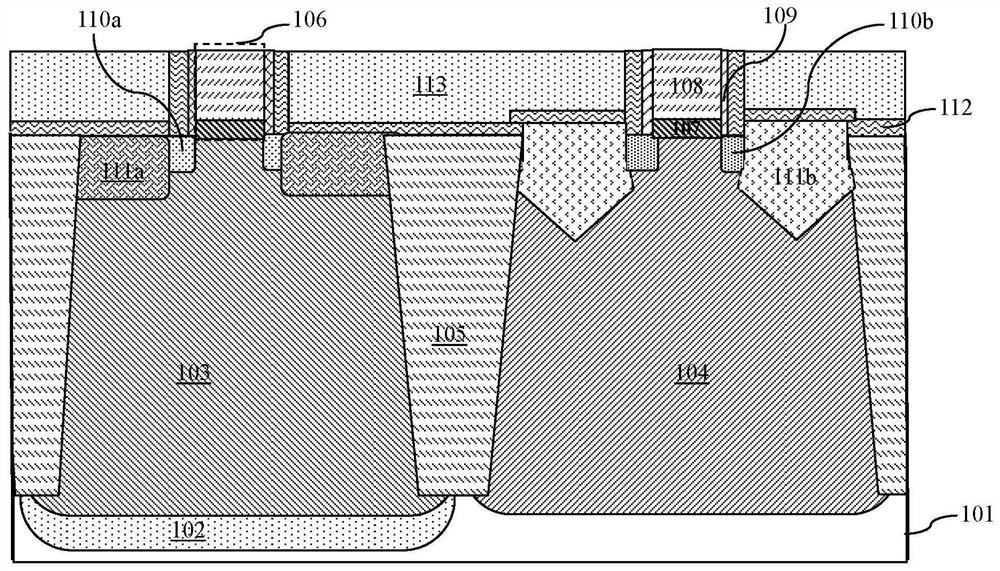

[0045] The bottom recess 1152 is composed of the removed area of the dummy gate structure 106 , please refer to the dummy gate structure 106 Figure 2A As shown, spacers 109 are formed on the sides of the dummy gate structure 106 , and a top surface of the semiconductor substrate 101 outside the spacers 109 is formed with a top surface that is the same as the top surface of the dummy gate structure 106 . The zeroth layer of the interlayer film 113, after the dummy gate structure 106 is removed, the inner sides of the sidewall spacers 109 form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com