Gear with at least two gearing stages, a linear actuator comprising such a gear and a table leg comrising such a linear actuator

A transmission device and actuator technology, which is applied in the field of raising columns, can solve problems such as power transmission and noise not being optimal, crown gear and helical gear tooth connection complex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

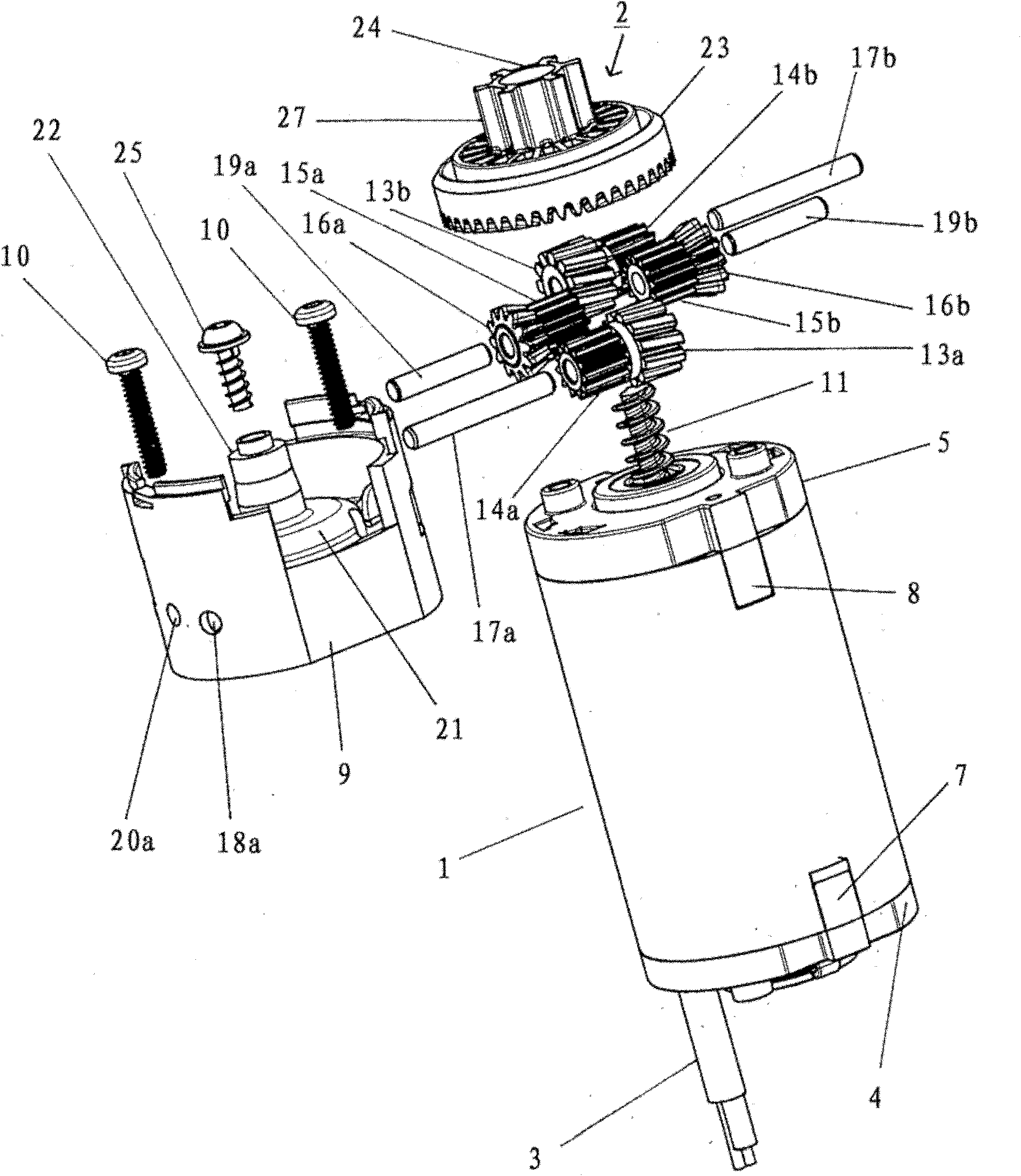

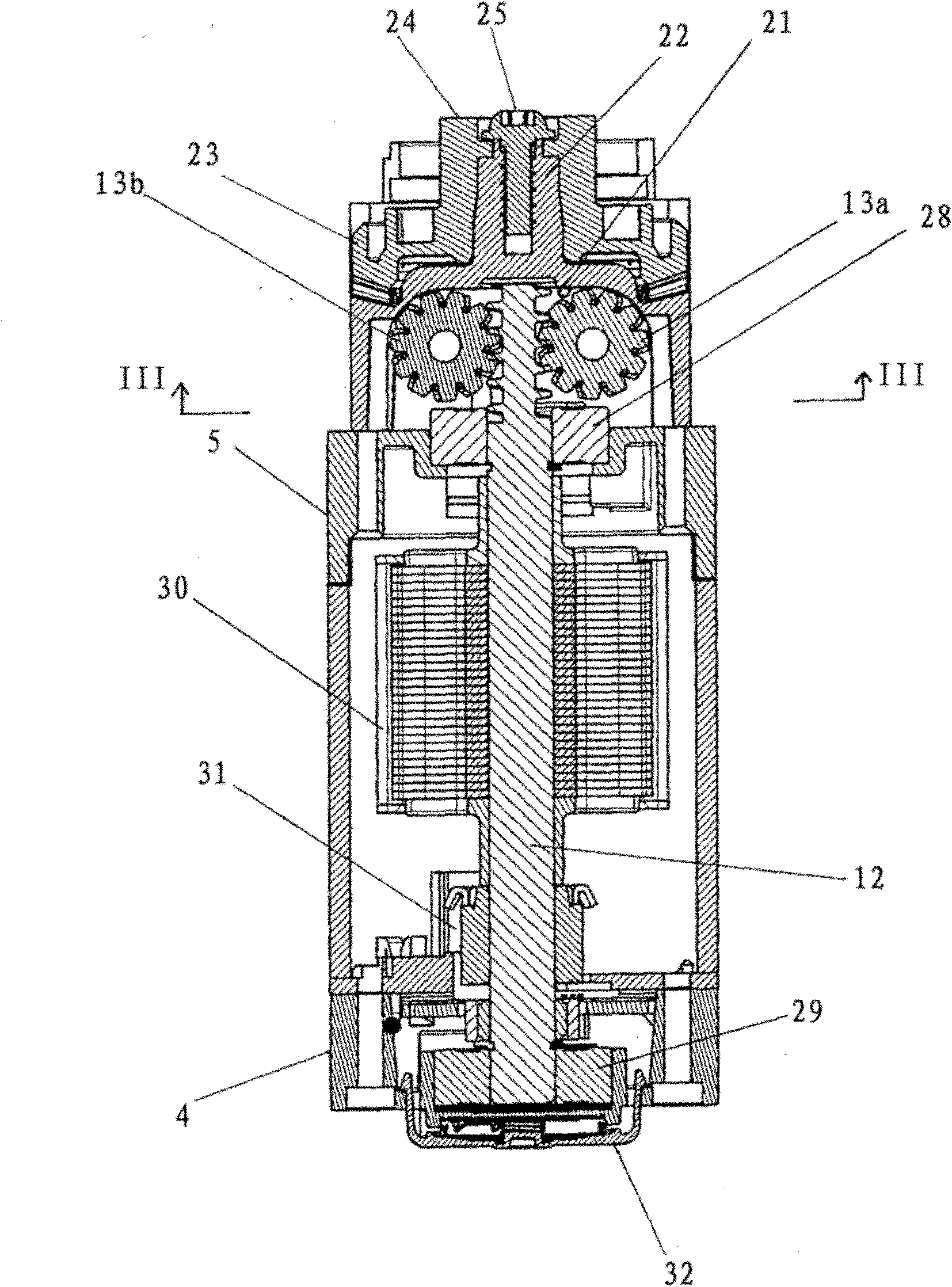

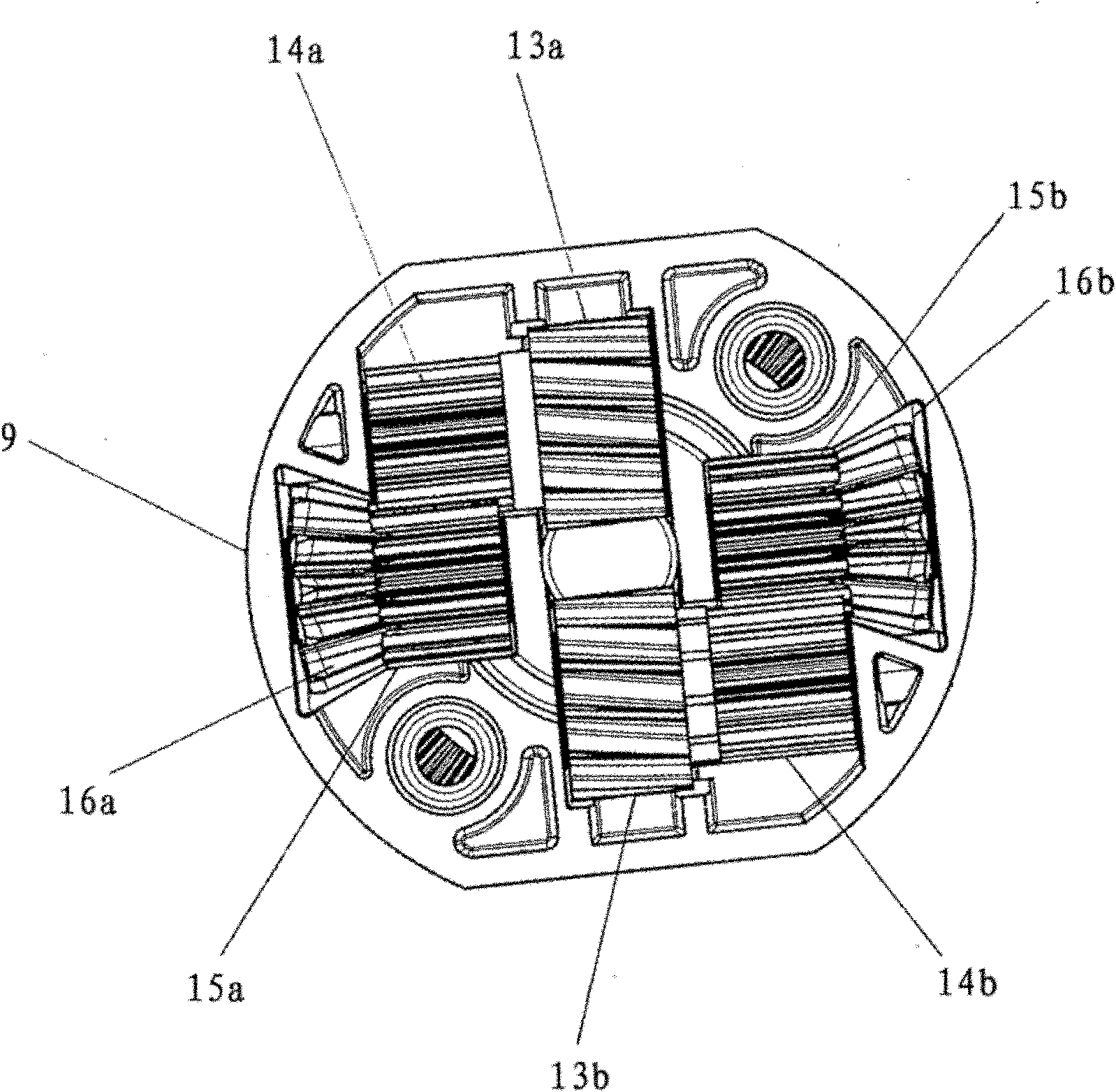

[0030] exist figure 1 An exploded view of a permanent magnet, low voltage motor 1 with an in-line front transmission 2 is shown in . The motor 1 is connected to a power source and a controller through a cable 3 . Furthermore, the motor 1 comprises a motor housing consisting of an outer cylindrical sheath and a rear cover 4 and a front cover 5 having snap locking legs 7, 8 for snapping Snaps on to the cylindrical sheath. The front transmission comprises a cylindrical transmission housing 9 which can be mounted on the front cover 5 by means of a pair of screws 10 . The transmission comprises a worm screw in the extension of the motor shaft 12 (cf. figure 2 ). The worm 11 meshes with a pair of diametrically positioned worm wheels 13a, 13b. The worm 11 is made of steel, while the worm wheels 13a, 13b are made of plastic for low noise levels. There are also spur gears 14a, 14b integral with the worm wheels 13a, 13b, which mesh with further corresponding spur gears 15a, 15b. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com