Bioreactor cultivation method suitable for sunlight greenhouse production

A bioreactor and solar greenhouse technology, applied in the field of bioreactor cultivation, can solve the problems of fertilizer consumption, increase air humidity, increase production costs, etc., and achieve the effect of saving fertilizer and reducing air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

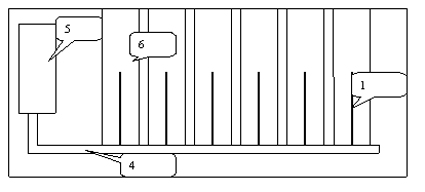

[0014] 1. Prepare rice straw or wheat straw or corn straw (6-10 tons / mu) before planting, special straw starter (30-40 kg / mu, special starter for Shandong Fulder straw), 20mm diameter line pipe (200-250 m / mu), 32mm diameter water pipe (80-100 m / mu), elbows, tees, 32 to 20 direct, urea (2-3 kg / mu).

[0015] 2. Open matrix groove 3 to soil 2, the groove depth is 40cm, the groove width is 110cm, and the groove length can be determined according to the span of the greenhouse (generally 5-6.5 meters).

[0016] 3. Use a baler to pack the prepared straw into straw bales with a specification of 40×40×110cm, and the straw bales need to be packed tightly (15-17 kg / piece).

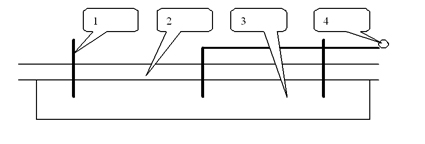

[0017] 4. Fill the packed grass bales neatly into the matrix groove 3, and then prepare the wire pipes with a diameter of 20cm according to the specifications and quantities of 3 per ridge and 35cm per ridge, and insert one in the front, middle and back of each ridge. When inserting, the lower part is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com