Cold forging press machine with large rated tonnage point

A large nominal force and press technology, which is applied in the field of cold forging presses, can solve the problems of easy damage to the crankshaft and the large torque required to drive the crankshaft, and achieve the effects of ensuring forging accuracy, stable average speed, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

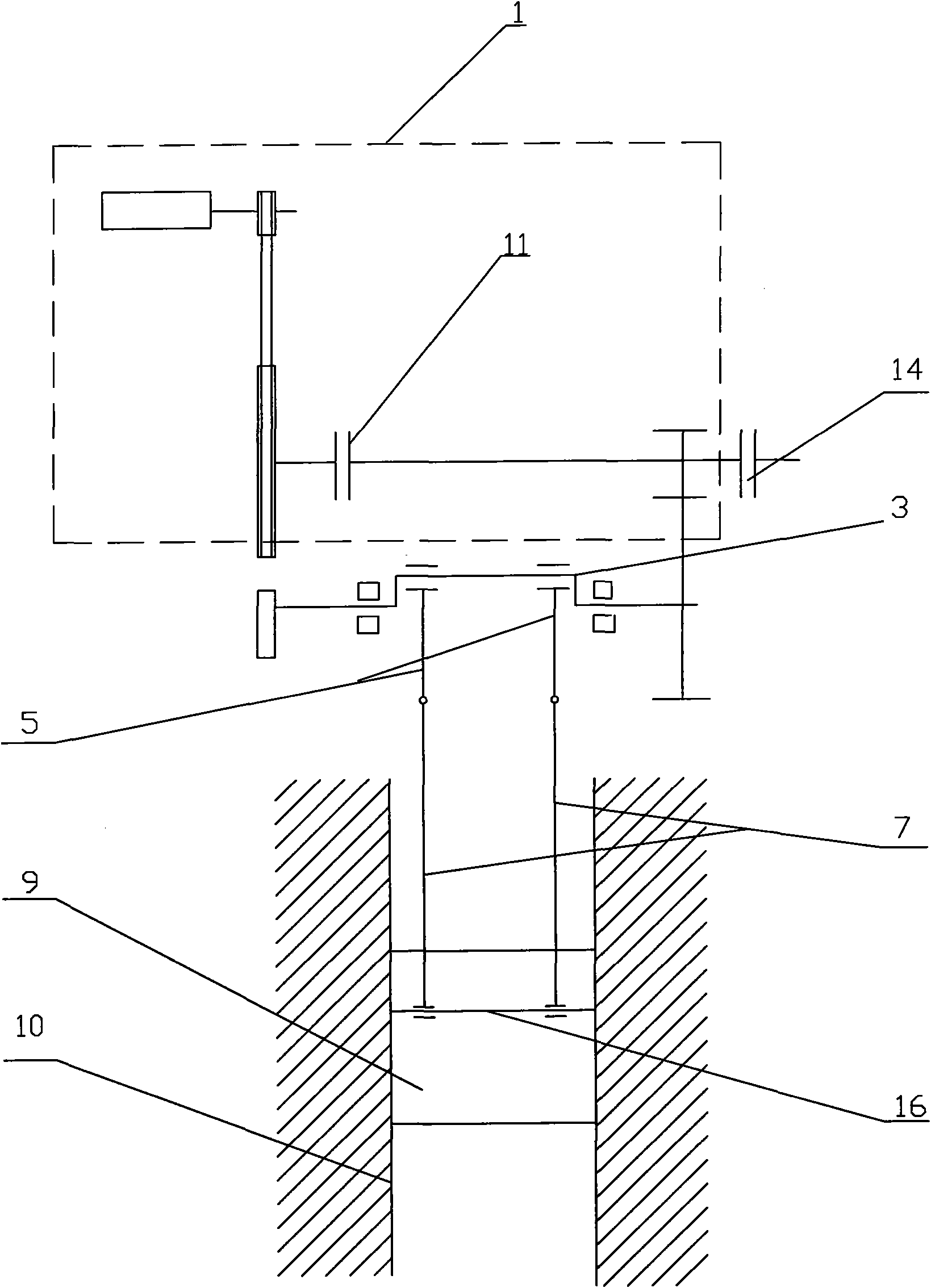

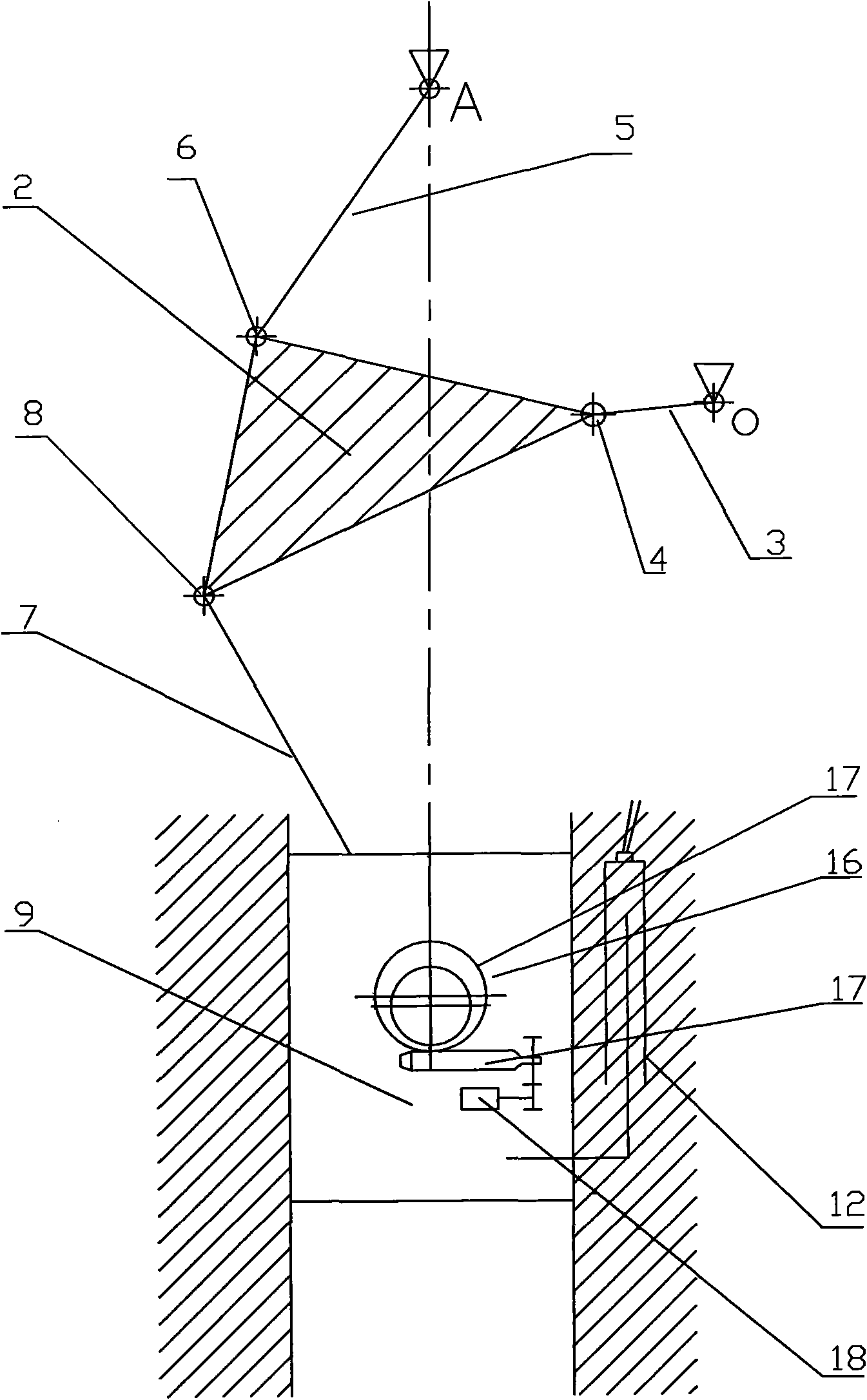

[0030] Such as figure 1 and figure 2 Shown, a kind of large nominal force stroke cold forging press of embodiment 1 comprises

[0031] Fuselage, driving device 1, multi-link mechanism, slide block 9, and guide rail 10, wherein said multi-link mechanism includes

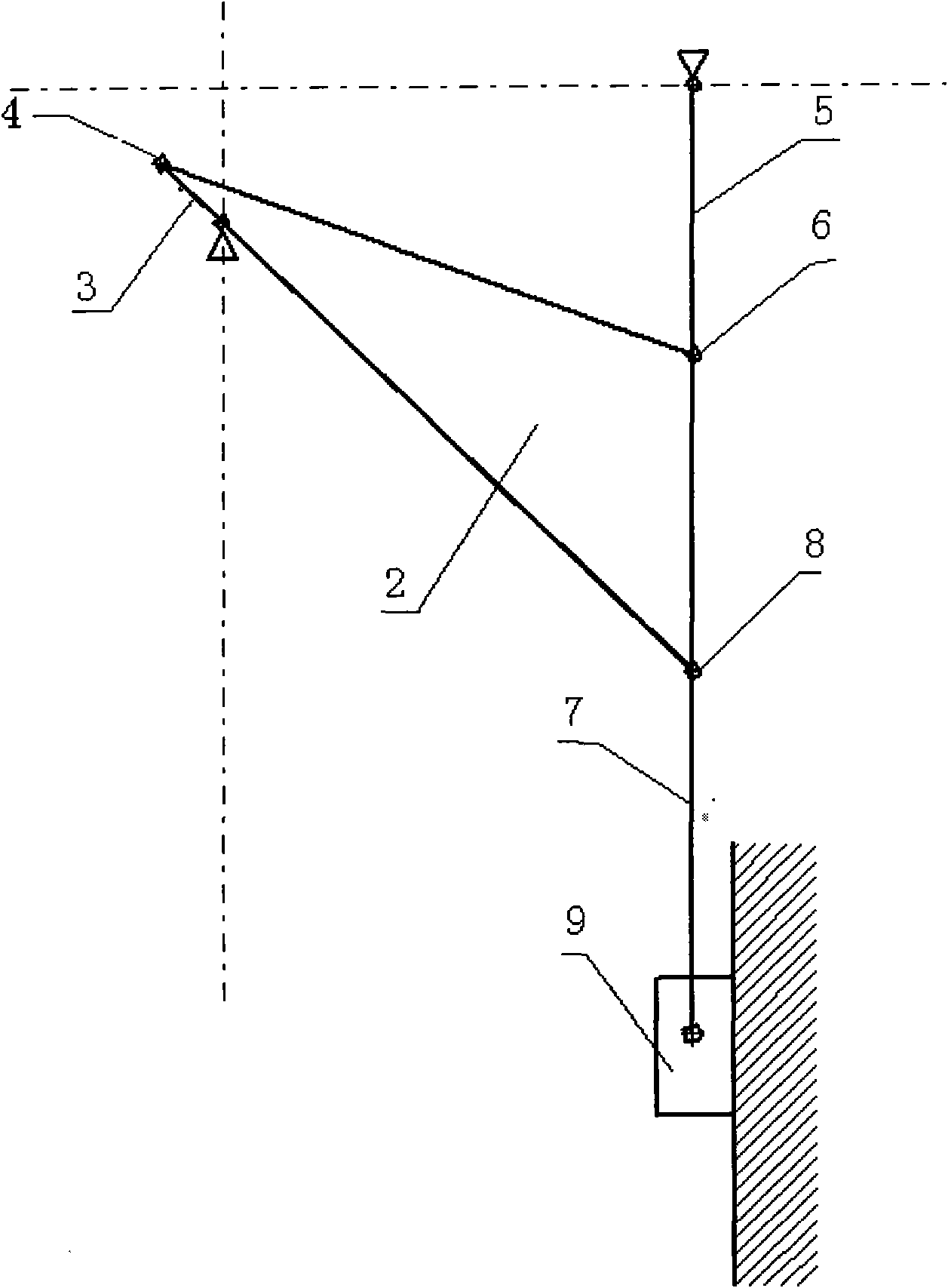

[0032] A triangular connecting rod 2, the triangular connecting rod 2 is in a triangular shape,

[0033] A rotating member, the rotating member includes a rotating shaft, and an eccentric part with the rotating shaft as the center of rotation, wherein the rotating shaft drives the eccentric part to rotate under the drive of the driving device 1, and the eccentric Part is hinged with the first apex 4 of the triangular connecting rod 2,

[0034] A rocker 5, one end of the rocker 5 is hinged on the fuselage, the hinge is the swing center of the rocker 5, and the other end is hinged with the second apex 6 of the triangular connecting rod 2,

[0035] Slider connecting rod 7, the upper end of said slider connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com