Laser paint-removing system and method

A paint and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low effect accuracy, poor control of occupation, location and depth of paint removal, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

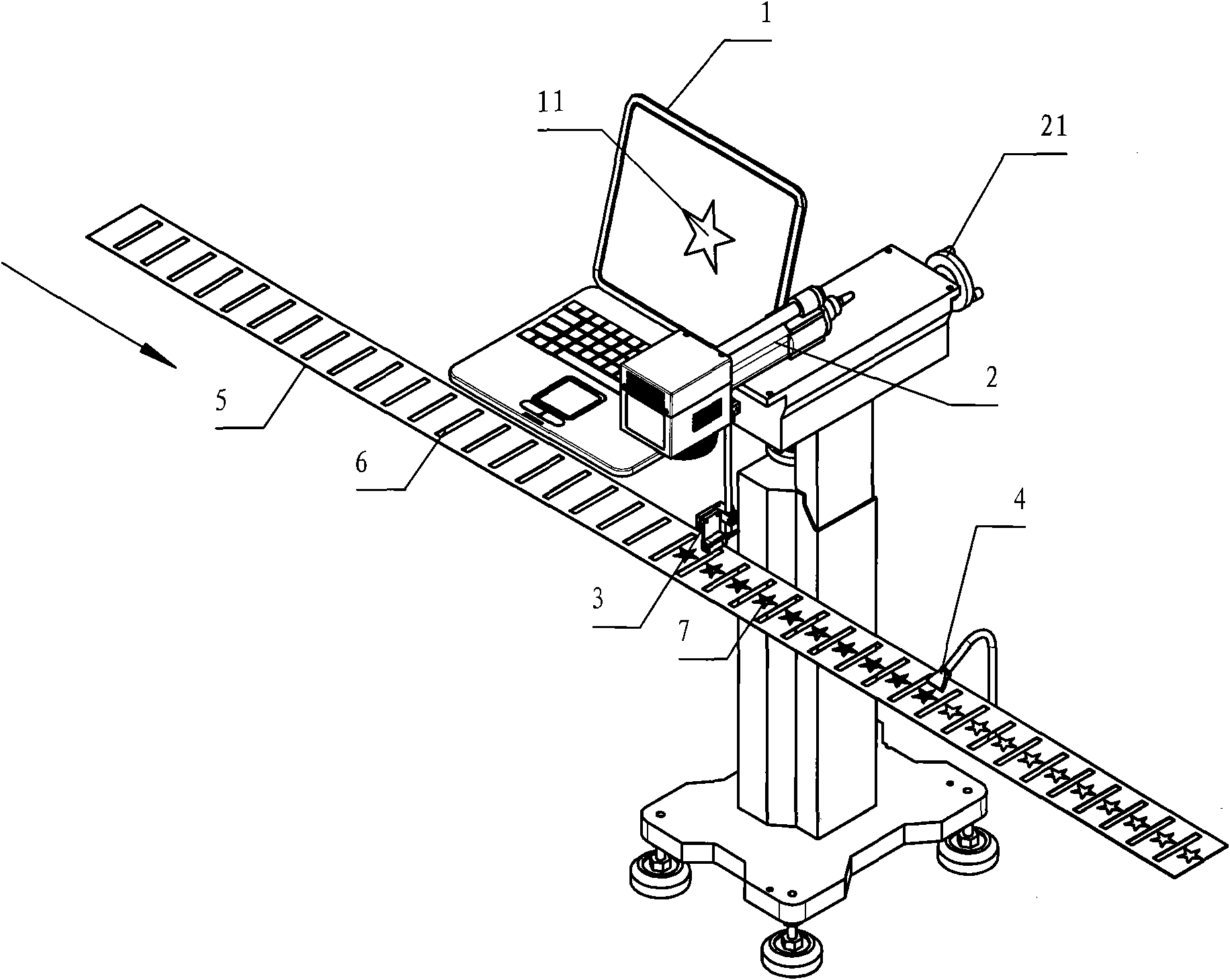

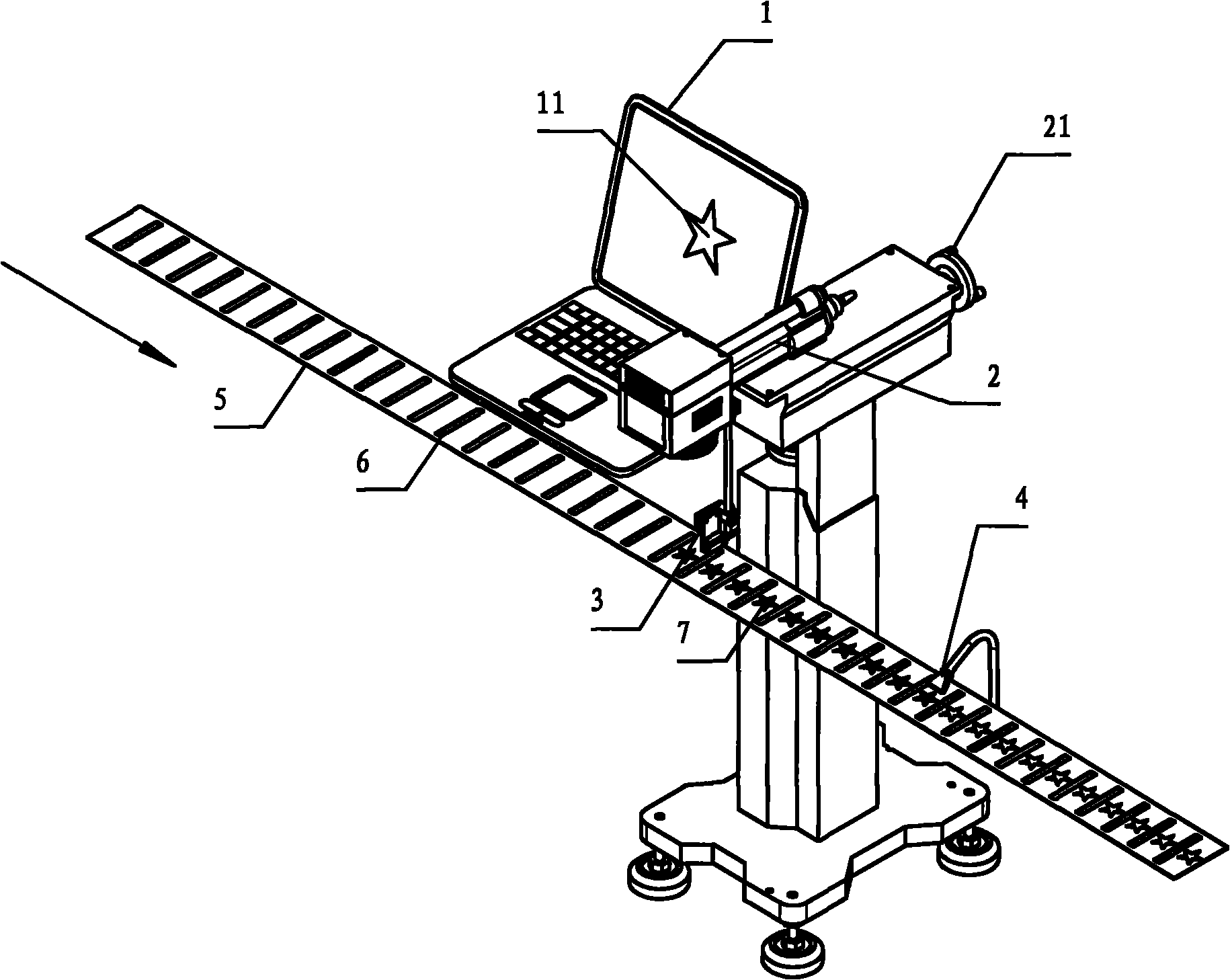

Examples

Embodiment 2

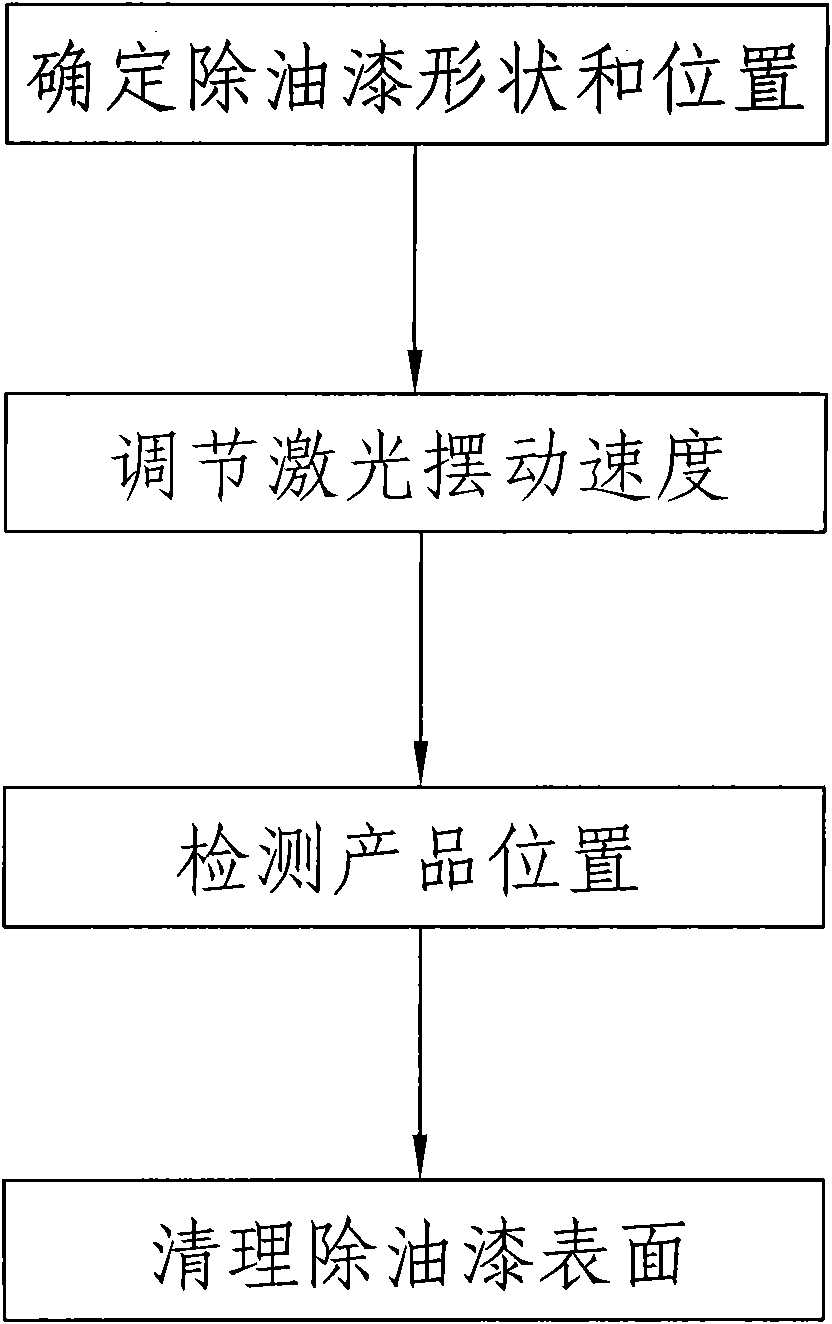

[0029] Example 2, reference 2. This embodiment has described the method that utilizes the laser paint removal system of above-mentioned embodiment to remove paint, and this method comprises the following steps:

[0030] (1) Determine the shape and position of paint removal, and utilize the laser marking software to edit the shape and position of paint removal on the control device 1;

[0031] (2) Adjust the laser swing speed. During the operation of the system, the laser marking machine 2 detects the movement speed of the assembly line 5 in real time, and compensates the laser swing speed to reach the product 6 moving on the assembly line 5 .

[0032] (3) Detect the position of the product. When the photoelectric switch 3 detects the product 6 to be depainted, the system triggers the laser marking machine 2 to emit laser light, and burns the surface of the product 6 to be depainted;

[0033] (4) Cleaning and removing the paint surface, the burnt product 6 continues to move to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com