Method for enhancing lateral stiffness of multi-walled nanotube device by irradiation of electron beam

A technology of multi-walled nanotubes and electron beam irradiation, applied in the field of field emission nanotube devices, can solve problems such as nanotube probes with large lateral stiffness, and achieve the effects of good strength, good flexibility, and enhanced stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

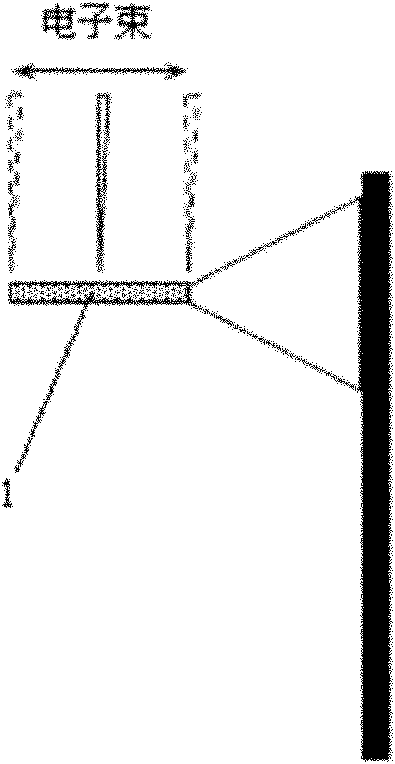

[0016] The basic principle diagram of embodiment 1 is shown in figure 2 : Use the same electron beam irradiation parameters to irradiate the nanotubes of the nanotube device as a whole, and 1 in the figure represents the multi-walled nanotubes whose overall stiffness is optimized after irradiation;

Embodiment 2

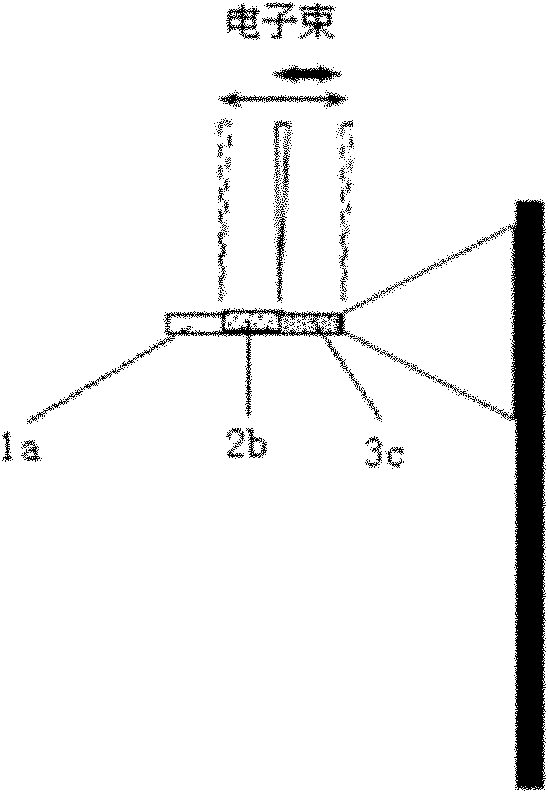

[0017] The basic principle diagram of embodiment 2 is shown in image 3 : Different electron beam irradiation parameters are used to irradiate different parts of the nanotube device. For the nanotube part of the nanotube device near the free end, that is image 3 In 1b, the electron beam with small beam current (100pA~1000pA) and low accelerating voltage (1kV~5kV) is used to irradiate it for 10s, and the irradiation intensity is reduced to ensure that the nanotube has good flexibility at this position; while in The position of the nanotube away from the dangling end and close to the substrate, that is, image 3 In 1c, the electron beam with large beam current (1nA~10nA) and high accelerating voltage (5kV~30kV) is used to irradiate it for 30s to increase the number of chemical bonds between layers and achieve the purpose of enhancing its stiffness;

[0018] 4. After reaching the expected parameters, stop the electron beam irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com